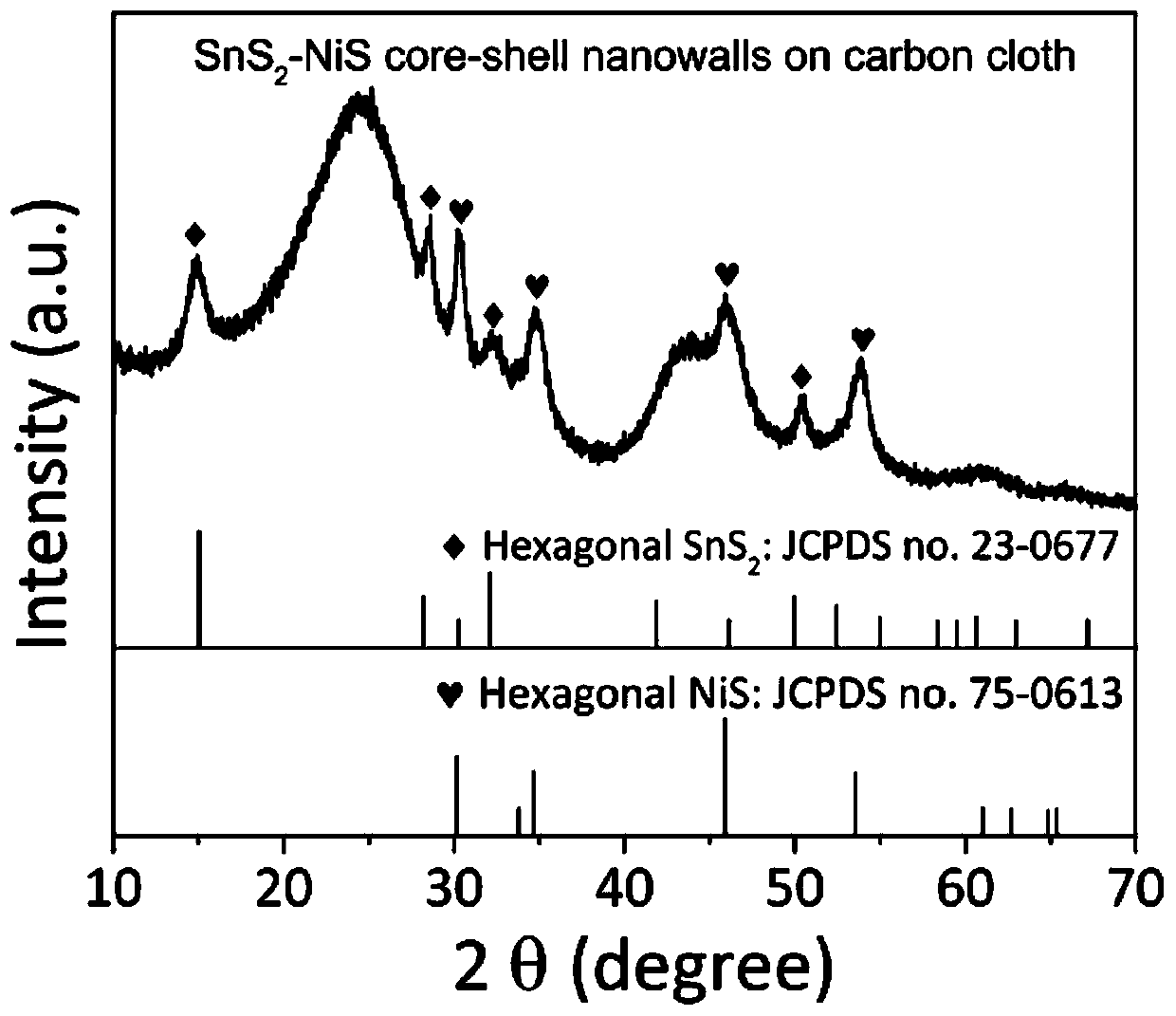

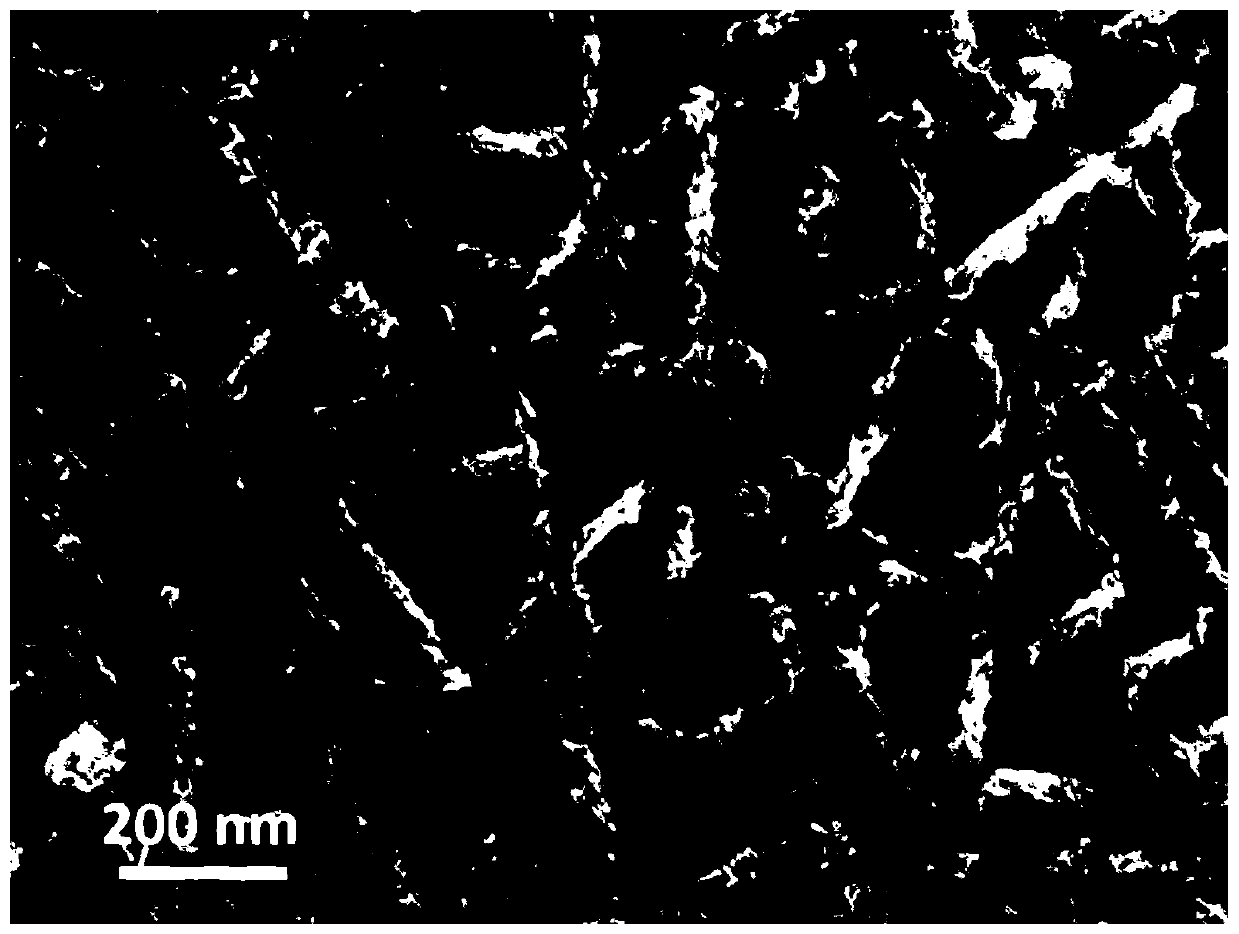

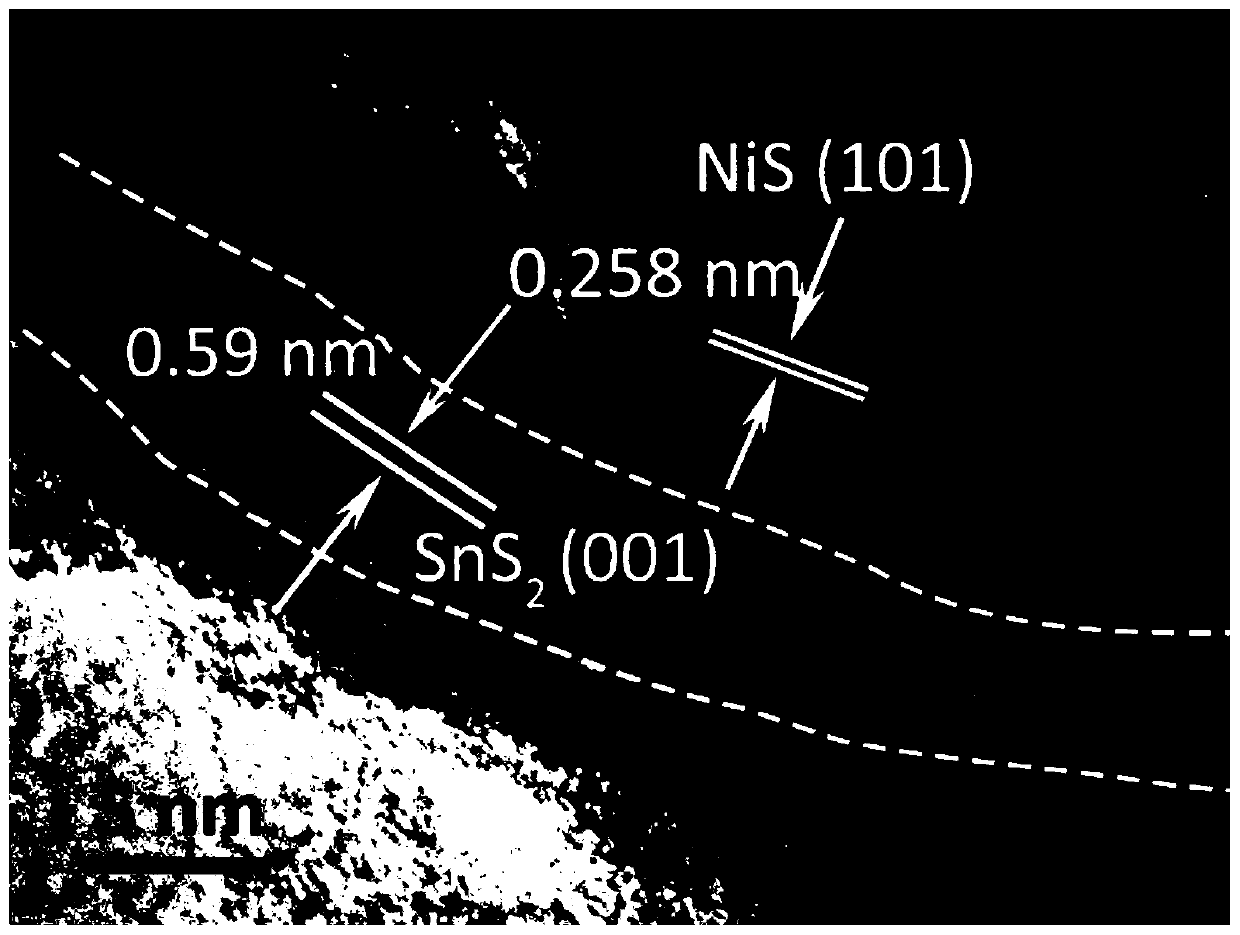

Conductive substrate loaded tin disulfide-nickel sulfide core-shell heterogeneous porous nano wall array structure and preparation method thereof

A tin disulfide, array structure technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., to achieve the effects of improving cycle stability, high product yield, and simple and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the tin disulfide-nickel sulfide core-shell heterogeneous porous nano-wall array structure supported by the conductive substrate of the present invention comprises the following steps and contents:

[0033] (1) First, dissolve tin tetrachloride and thioacetamide in absolute ethanol in a beaker; then, transfer to an autoclave, and place a piece of clean conductive substrate vertically. Seal the reaction kettle and put it into an electric furnace, then heat it from room temperature to 140-180°C at a rate of 5-25°C / min, and keep it warm for 4-12 hours. After naturally cooling to room temperature, open the reaction kettle, take out the substrate, alternately rinse with deionized water and alcohol for 3-5 times, and dry at 50-80°C for 8-12 hours to obtain the conductive substrate-supported tin disulfide nanoparticles. slice samples.

[0034] (2) In a beaker, nickel chloride is dissolved in absolute ethanol to obtain a uniform solution; after being ...

Embodiment 1

[0041] Example 1: First, in a 100 mL beaker, 0.631 g of tin tetrachloride pentahydrate and 0.270 g of thioacetamide were dissolved in 60 mL of absolute ethanol. Then, it was transferred into a 100mL autoclave, and a piece of pre-cleaned carbon cloth (3.7×5cm 2 ). The reaction kettle was sealed and placed in an electric furnace, then heated from room temperature to 160°C at a rate of 15°C / min, and kept for 6 hours. After naturally cooling to room temperature, the reactor was opened, the carbon cloth was taken out, rinsed four times with deionized water and alcohol alternately, and dried at 60°C for 12 hours to obtain the carbon cloth-supported tin disulfide nanosheet sample.

[0042] In another 50mL beaker, dissolve 0.143g of nickel chloride tetrahydrate in 30mL of absolute ethanol to obtain a uniform solution; after transferring to a 50mL autoclave, put a piece of carbon cloth obtained in the above steps vertically The tin disulfide nanosheet sample (2.5×3.7cm 2 ). The rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com