Horizontal Mechanochemical Ball Mill and Its Forming Process Parameter Analysis Method

A mechanochemical and analytical method technology, applied in the field of horizontal mechanochemical ball milling device and its forming process parameter analysis, can solve the problems of only considering the collision, ignoring the collision between the ball and other contact surfaces, etc., so as to improve the structural strength and improve the collision energy. , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

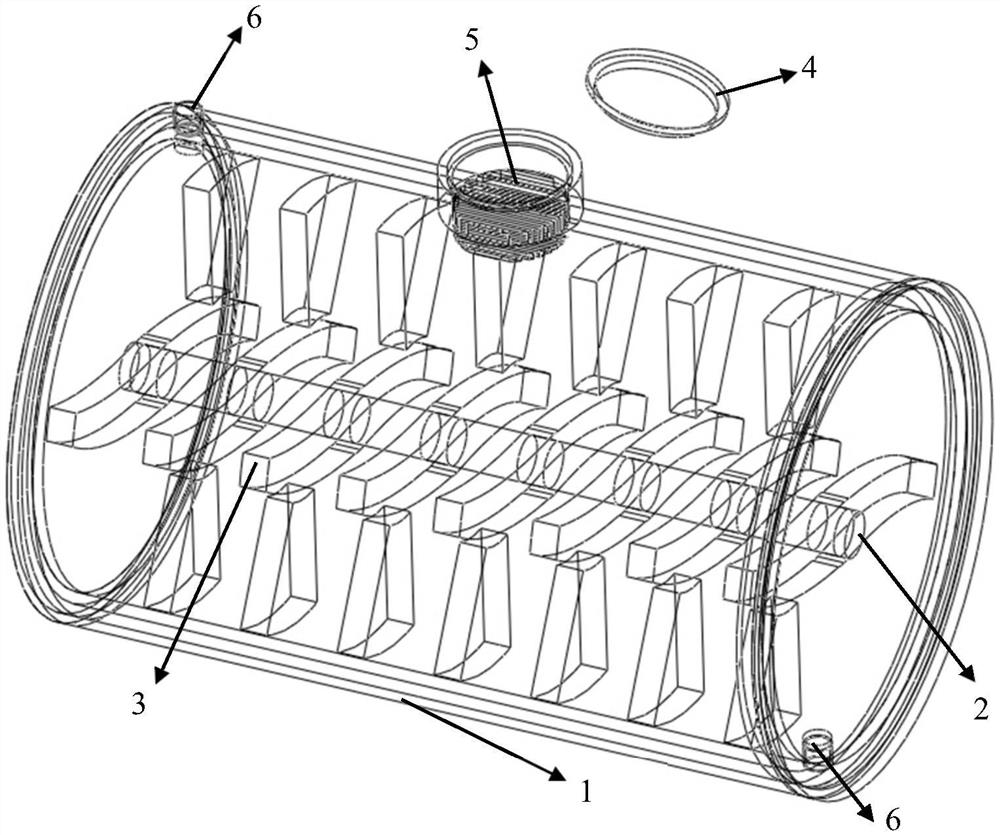

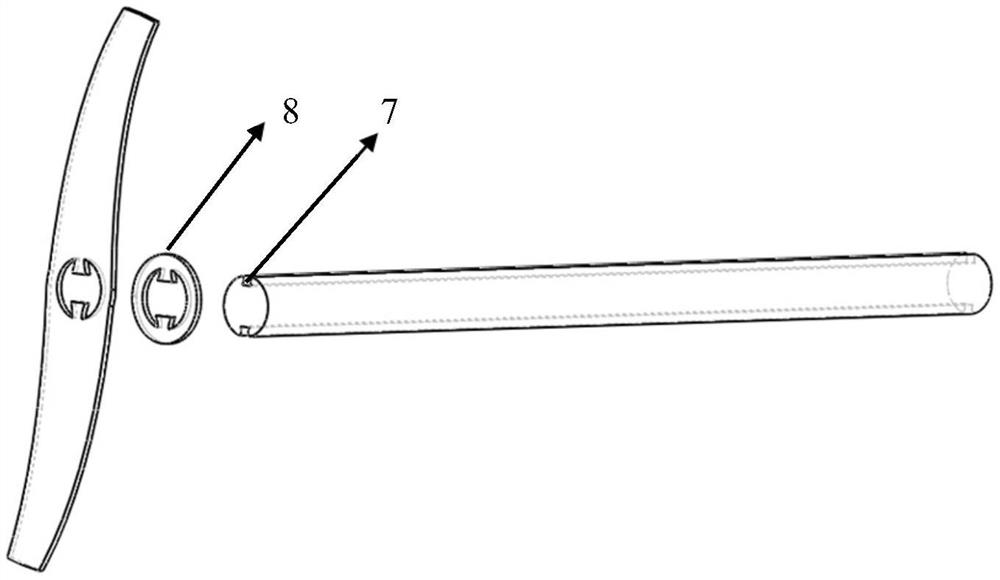

[0034] Use mechanical design software (Solidworks) to build a physical model, set the inner length of the cylinder to 1600mm, the inner diameter to 1000mm, the outer length to 1700mm, and the outer diameter to 1100mm; the length of the main shaft to 1700mm, and the diameter to 150mm; 150mm, all blades are installed on the main shaft.

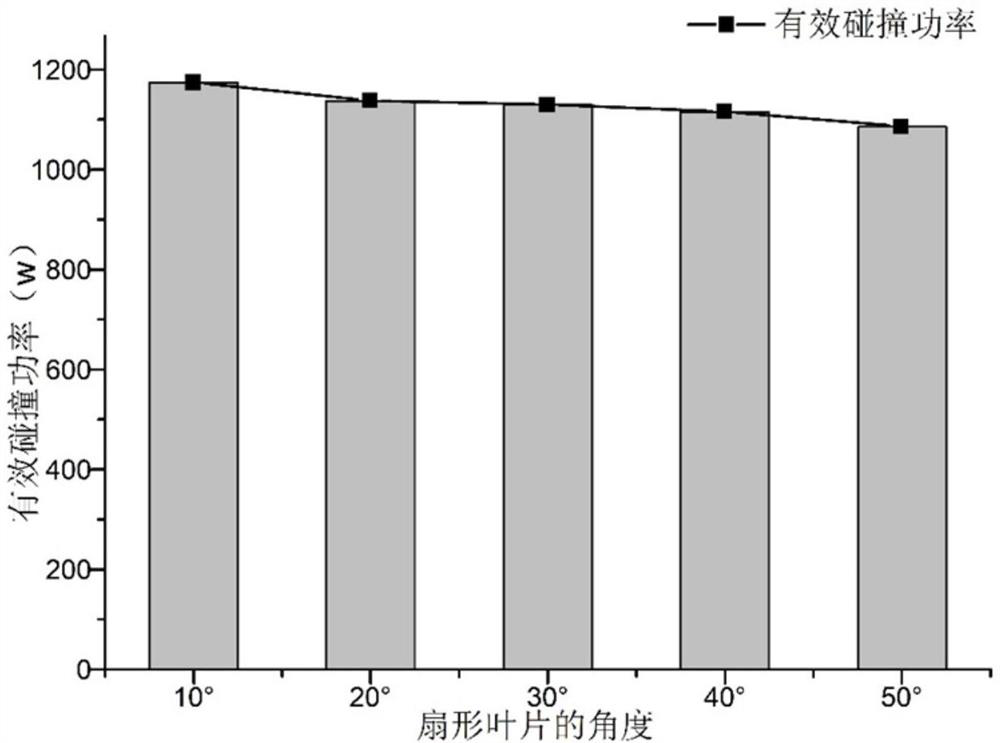

[0035] Among them, the number of blade groups is 48 groups, the total filling rate is 5%, and the blade width is 10mm. Gradient change blade fan ring angle 10°-50°, respectively import the built model into the discrete element software (DEM) to generate 3000 stainless steel grinding balls, the diameter of the grinding ball is 30mm, the spindle speed is 250mm, set the running time 0-6s, and complete the simulation After the process, output the relative velocity v of the normal phase between the ball and the ball, the ball and the blade, and the ball and the inner wall of the cylinder N and the collision frequency N, so as to calculate the total ...

Embodiment 2

[0038] Use mechanical design software (Solidworks) to build a physical model, set the inner length of the cylinder to 1600mm, the inner diameter to 1000mm, the outer length to 1700mm, and the outer diameter to 1100mm; the length of the main shaft to 1700mm, and the diameter to 150mm; 150mm, all blades are installed on the main shaft.

[0039] Among them, the blade fan ring angle is 30°, the blade filling rate is set to 2.5%, 5%, 10%, and 15%, respectively, and the number of blade groups is set to 16, 24, 32, and 48 under each group of filling rate. The built model is imported into the discrete element software (DEM) to generate 3000 stainless steel balls, the diameter of the grinding ball is 30mm, the spindle speed is 250rpm, and the running time is set to 0-6s. After the simulation process is completed, the output of balls and balls, balls and blades, balls and cylinders The normal phase relative velocity v of the wall N and the collision frequency N, so as to calculate the ...

Embodiment 3

[0050] The traditional horizontal ball mill installs all the blades on the main shaft, and relies on the rotation of the main shaft to drive the blades to drive the balls. In this example, the operation mode of the traditional horizontal ball mill is used as the control group, and some blades are installed on the cylinder wall to realize the independent movement of the cylinder wall and the main shaft. The simulation simulates the following three operation modes: ① all blades are installed on the main shaft, and only the main shaft rotates; ② half of the blades are installed on the cylinder, the cylinder remains stationary, and only the main shaft rotates; ③ half of the blades are installed on the cylinder, and both the cylinder and the main shaft rotate , and the speed is the same and the direction is opposite. The shape of the blade, the number of groups and the filling rate are all the same as in Example 2, and 16 groups of physical models are imported into the discrete ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com