Ultra-precise deterministic scribing processing system and method for secondary clamping of high-hardness and high-brittleness material

A technology of secondary clamping and processing system, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problem of large installation error and the inability of secondary clamping to determine the starting point and end point of the scribing path. and other problems to achieve the effect of reducing requirements and improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

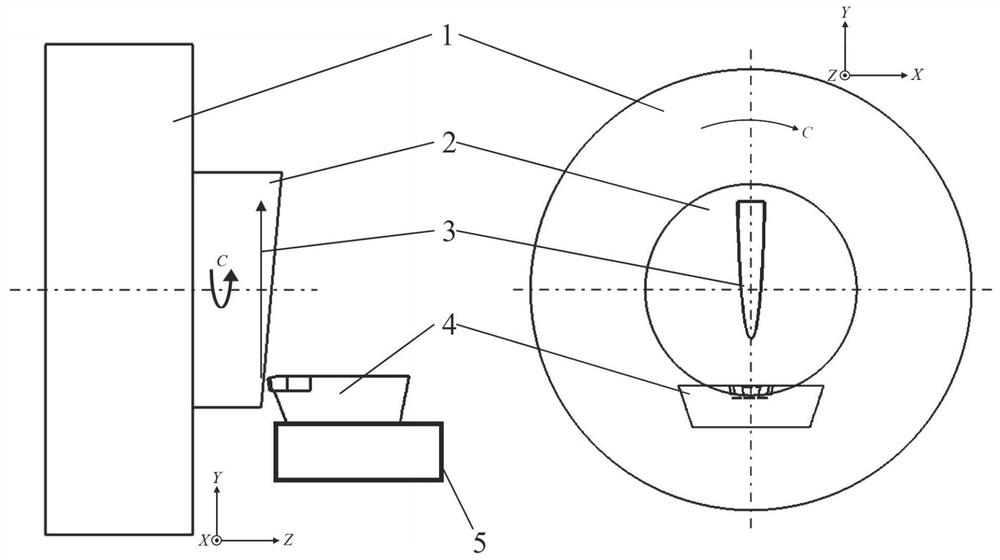

[0045] Firstly, the workpiece 2 is pre-processed on the surface and clamped on the vacuum chuck 1 of the machine tool. During the clamping process, you can choose to stick or mechanically tighten it. The geometric center of the workpiece surface should coincide with the spindle center as much as possible. The tool 4 is installed on the dynamometer. The force signal is collected on the sensor 5, and the sensor 5 is installed on the linear axis of the machine tool.

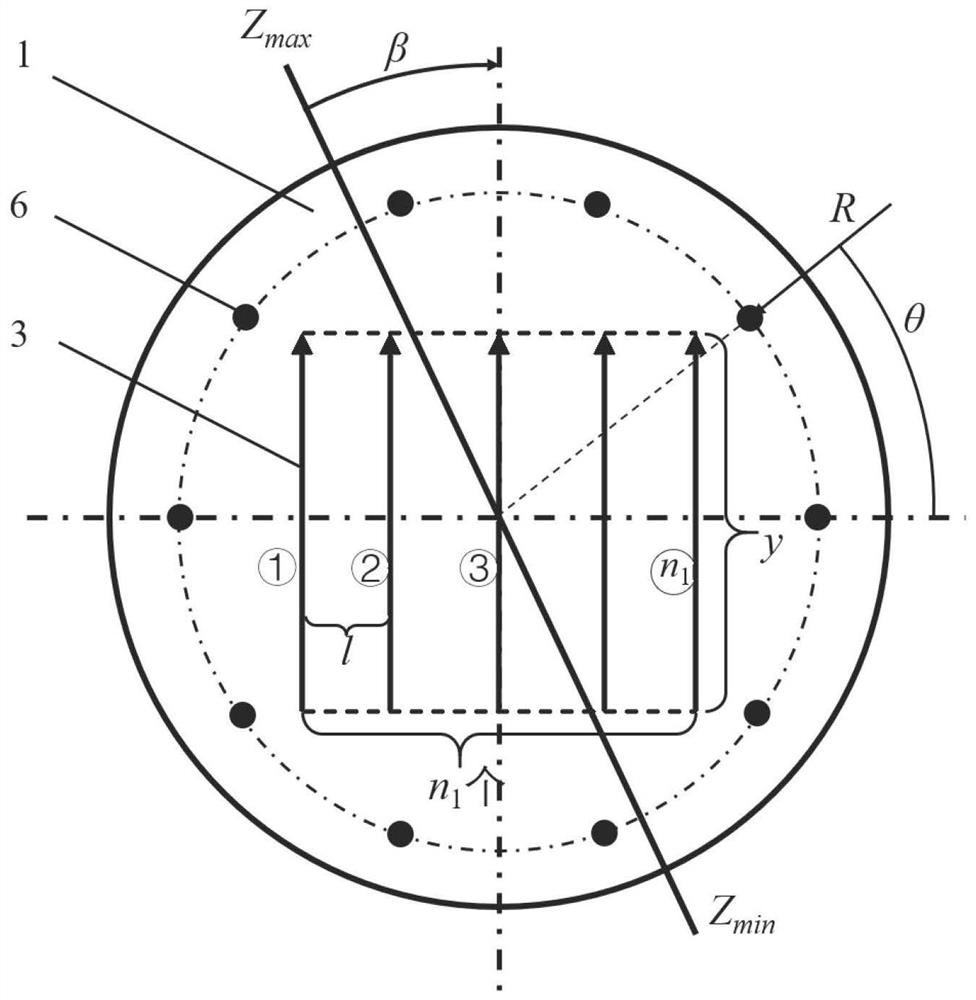

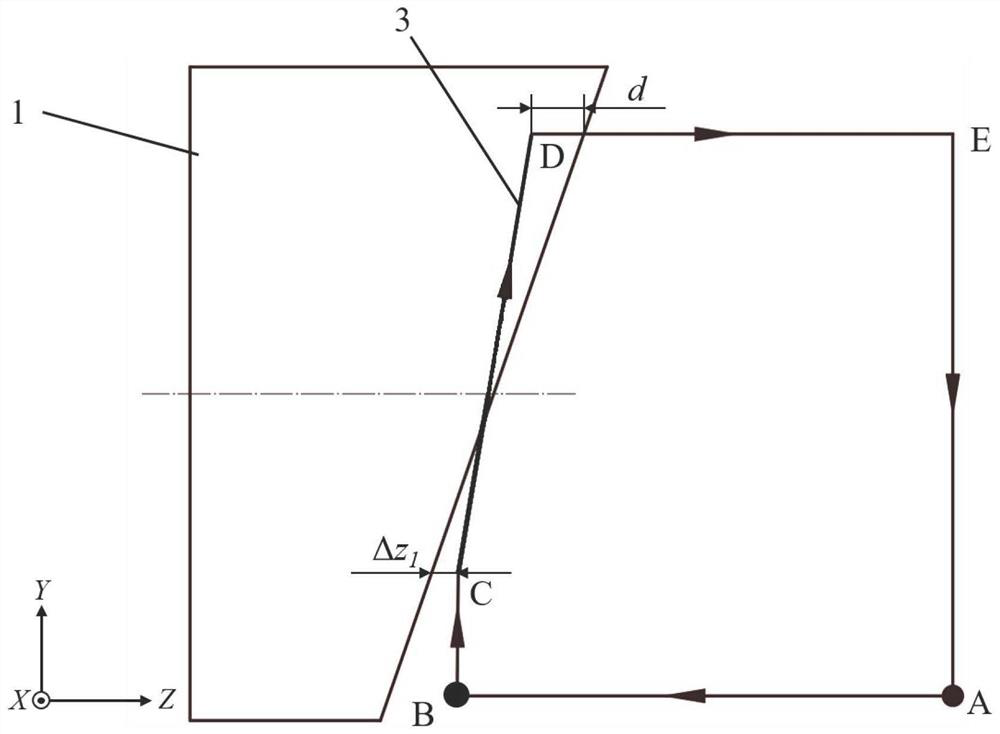

[0046] Then use the tool setting method to calculate the inclination and inclination direction of the workpiece surface. Such as figure 2 As shown, adjust the tool position so that the tool tip coincides with the center of the spindle, fix the workpiece spindle, position the C-axis position at the zero starting point here, and move the tool so that the tool tip position moves a distance of R in the positive direction of the X-axis. The circle with radius is all contained in the surface of the workpiece, and R shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com