Fructose diphosphate sodium reverse osmosis concentrated solution and preparation method thereof

A technology of sodium fructose diphosphate and reverse osmosis concentrate, applied in the field of medicine, can solve the problems of complicated preparation process, need to be studied, affecting the safety of use and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

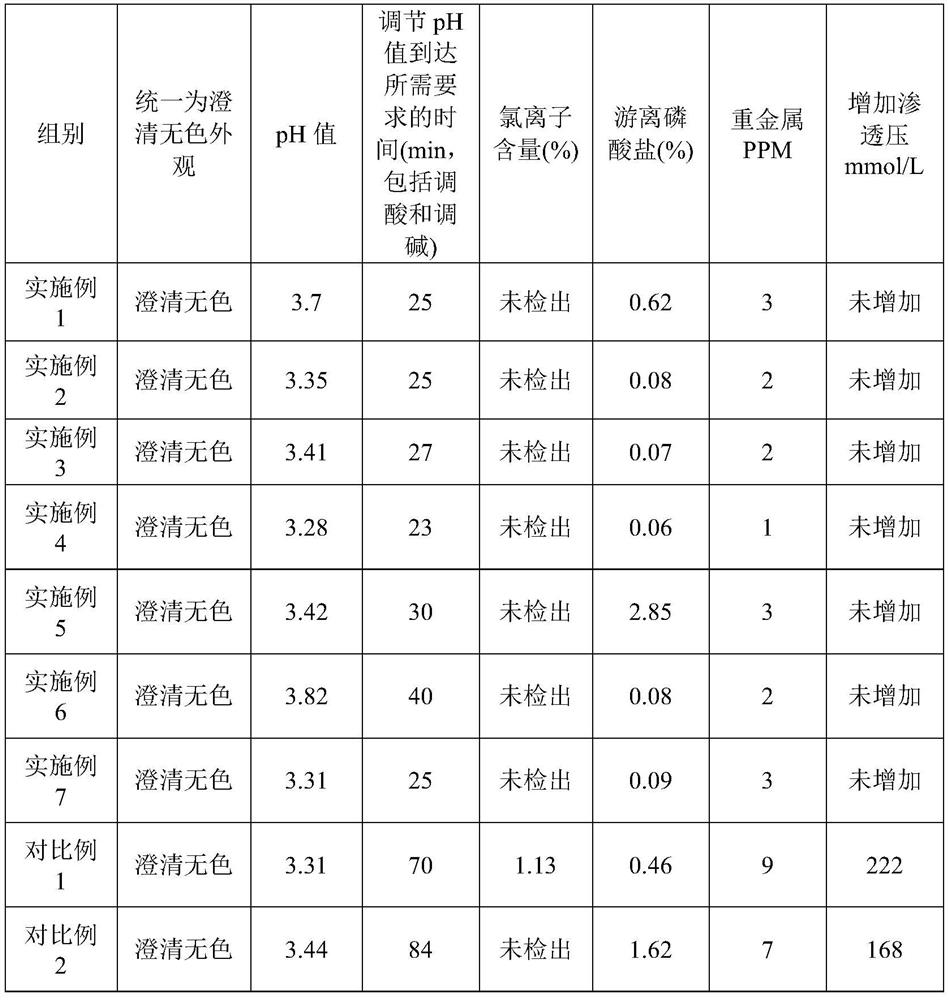

Examples

Embodiment 1

[0033] Add 2000L of purified water into the configuration tank, add 125kg of sodium fructose diphosphate raw material powder under stirring, then add purified water to 2250L, continue stirring for 30 minutes, and the pH of the solution is 5.7. D001 strong acidic cation exchange resin was used as the pH regulator to adjust the pH value to 3.2-3.5, the elution rate was 15L / h, and 2200L of the effluent was collected. Then, use about 200L of purified water to push the liquid medicine in the liquid distribution tank and the titanium rod filter into the decolorization tank. The decolorized filtrate is passed through a microporous filter to remove a small amount of carbon residue and then poured into the circulation tank. Then, use about 200L of purified water to push the liquid medicine in the decolorization tank and microporous filter into the circulation tank. Start the reverse osmosis machine to concentrate the liquid medicine in the circulation tank by 10 times. Start the spra...

Embodiment 2

[0035] Add 2000L of purified water into the configuration tank, add 125kg of sodium fructose diphosphate raw material powder under stirring, then add purified water to 2250L, continue stirring for 30 minutes, and the pH of the solution is 5.7. D001 strong acidic cation exchange resin was used as the pH regulator to adjust the pH value to 3.2-3.5, the elution rate was 15L / h, and 2200L of the effluent was collected. Add 1.1 kg of activated carbon for injection, stir evenly, and decolorize for 30 minutes under stirring. After filtering and decarburizing through a titanium rod filter, the decolorized filtrate circulates for 3-5 minutes, and then collects the decolorized filtrate into the decolorization tank. Now record the pH value of the decolorized filtrate to be 2.9, then adjust the pH of the decolorized solution with D201 type strongly basic anion exchange resin, the elution flow rate is 25L / h, then record the pH value of the eluent to be 3.3. Then, use about 200L of purified...

Embodiment 3

[0037] Add 2000L of purified water into the configuration tank, add 125kg of sodium fructose diphosphate raw material powder under stirring, then add purified water to 2250L, continue stirring for 30 minutes, and the pH of the solution is 5.5. D001 strong acidic cation exchange resin was used as the pH regulator to adjust the pH value to 3.2-3.5, the elution rate was 16L / h, and 2200L of the effluent was collected. Add 1.5 kg of activated carbon for injection, stir evenly, and decolorize for 30 minutes under stirring. After filtering and decarburizing through a titanium rod filter, the decolorized filtrate circulates for 3-5 minutes, and then collects the decolorized filtrate into the decolorization tank. Now record the pH value of the decolorized filtrate to be 2.8, then adjust the pH of the decolorized solution with D201 type strongly basic anion exchange resin, the elution flow rate is 18L / h, then record the pH value of the eluent to be 3.4. Then, use about 200L of purified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com