Silicification modified zero-valent iron and preparation method and application thereof

A zero-valent iron, modified technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc. The effect of fixed performance, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

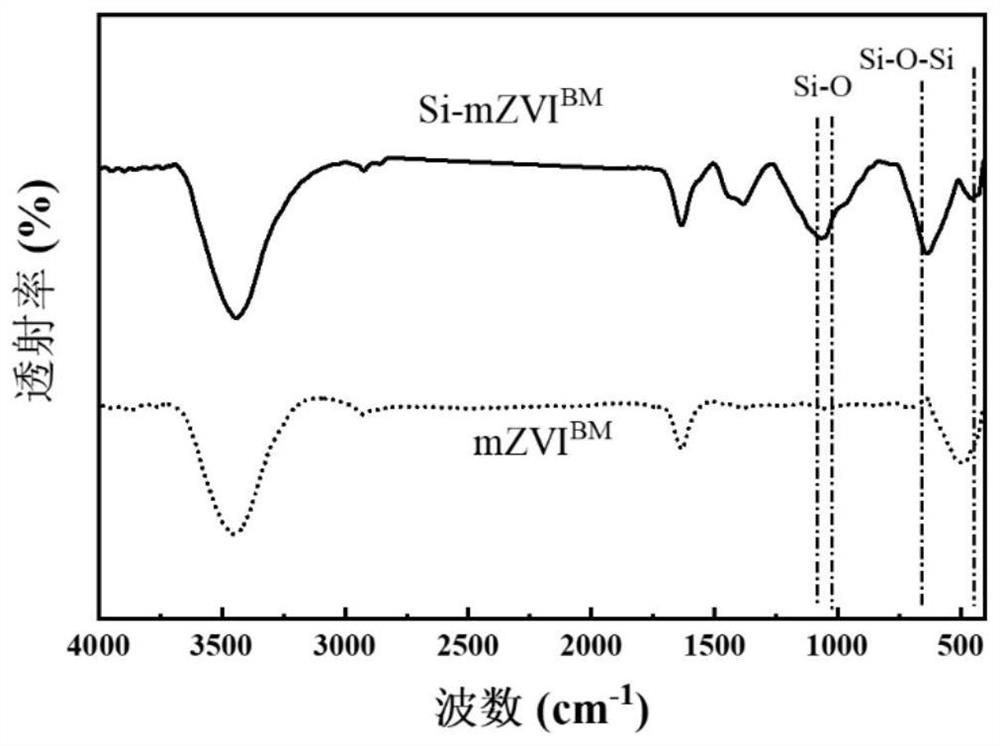

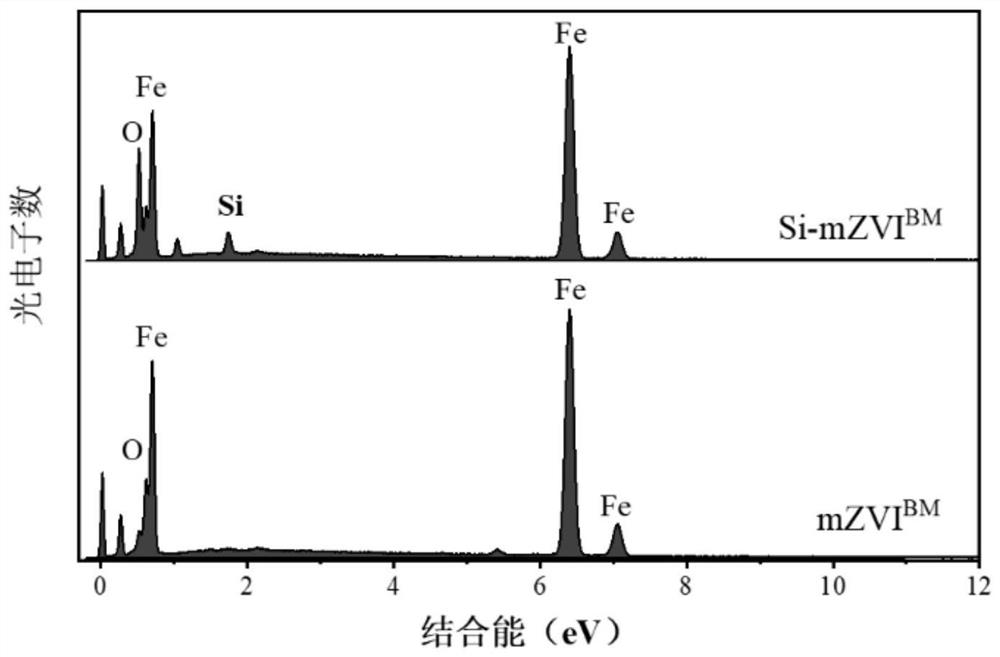

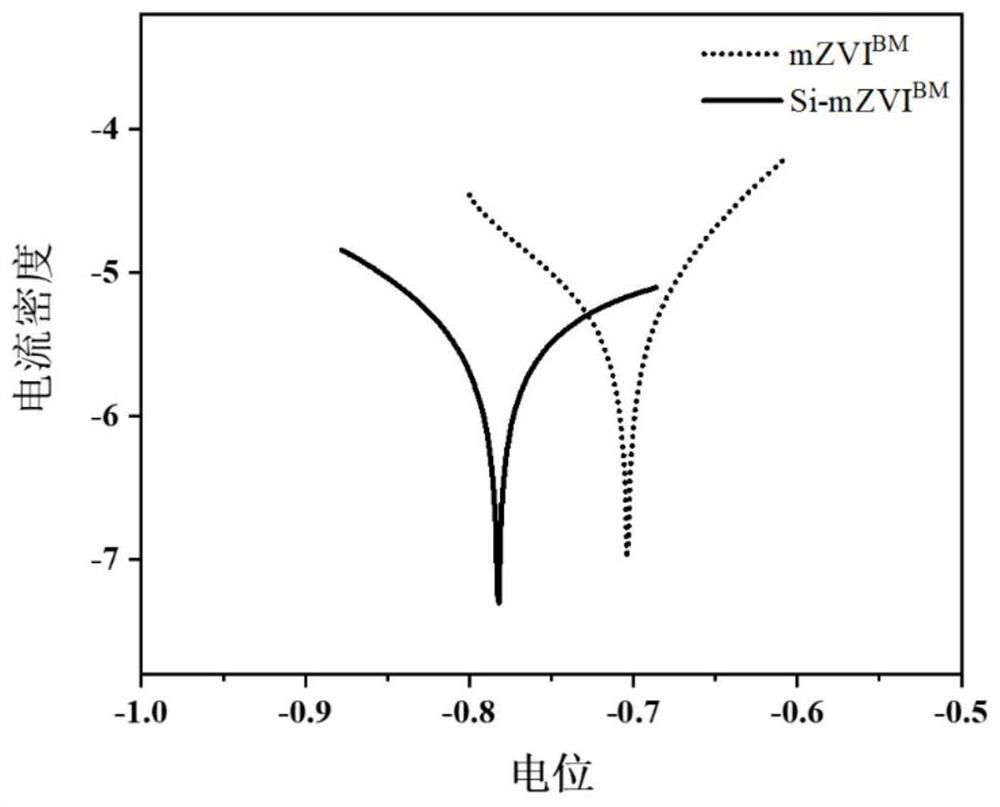

[0039] 5 g of reduced micron iron powder and 0.16 g of layered sodium disilicate were mixed and placed in a ball mill jar, ball milled for 4 hours under an argon atmosphere at a milling speed of 500 rpm / min, washed and dried.

[0040] Taking 100mL of simulated hexavalent chromium polluted water body with a concentration of 2.5g / L as the remediation object, add 0.2g of the above-mentioned prepared iron silicide sample (Si-mZVI BM ), under constant temperature conditions, the rotating speed is 200rpm / min shaker reaction, after regular sampling, measure the hexavalent chromium content with a spectrophotometer.

[0041] At the same time, unsilicified ball-ground iron (mZVI) was milled in the same way BM ) is a controlled test, see the results Figure 4 shown. After 100 minutes of reaction, the removal rate of hexavalent chromium in the silicified modified zero-valent iron system reached 100%, while the removal rate of hexavalent chromium in the non-silicided iron system was less...

Embodiment 2

[0043] Take 10 grams of reduced micron iron powder, add 0, 0.165, 0.33, 0.66, 1, 1.3 g of sodium silicate respectively, mix them in a ball mill jar, and ball mill for 5 hours under an argon atmosphere at a ball mill speed of 550 rpm / min, wash Drying, respectively marked as mZVI BM 、1#mZVI BM 、2#mZVI BM 、3#mZVI BM 、4#mZVI BM and 5#mZVI BM .

[0044] Taking 100mL of simulated hexavalent chromium-contaminated water body with a concentration of 2g / L as the restoration object, add 0.2g of the silicified modified zero-valent iron sample prepared above, and react on a shaking table at a constant temperature with a rotation speed of 200rpm / min. After sampling, the content of hexavalent chromium was measured with a spectrophotometer, and the results were as follows: Figure 5 shown. 3#mZVI after 60min reaction BM The removal rate of hexavalent chromium reaches 97%, 4#mZVI BM Secondly, the removal rate of hexavalent chromium is 72%, and the removal of hexavalent chromium by all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com