A method for high-pressure olefin polymerization

An olefin polymerization, high-pressure technology, applied in the field of high-pressure olefin polymerization, can solve problems such as pipeline ethylene decomposition, high ethylene conversion rate, and blockage of outlet pipelines, so as to ensure sufficient decomposition and avoid the risk of ethylene decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

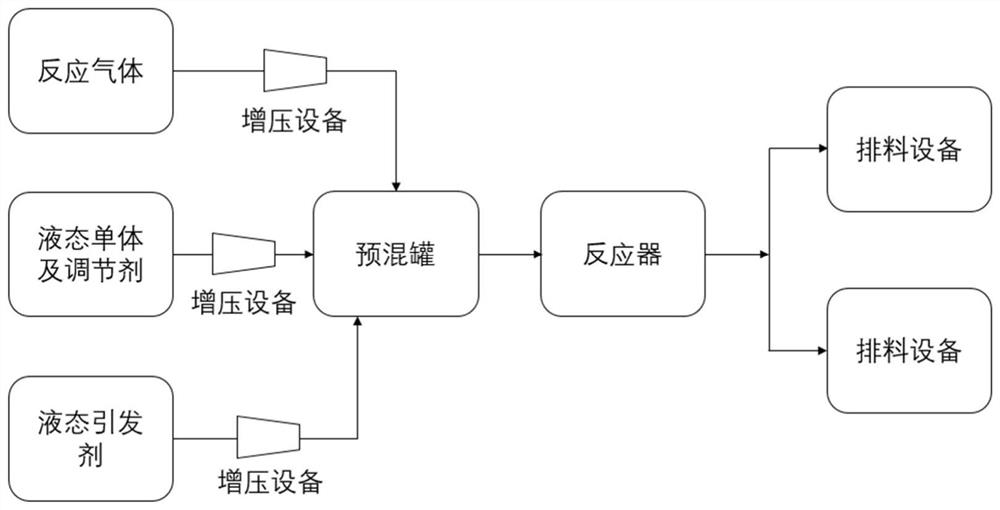

Method used

Image

Examples

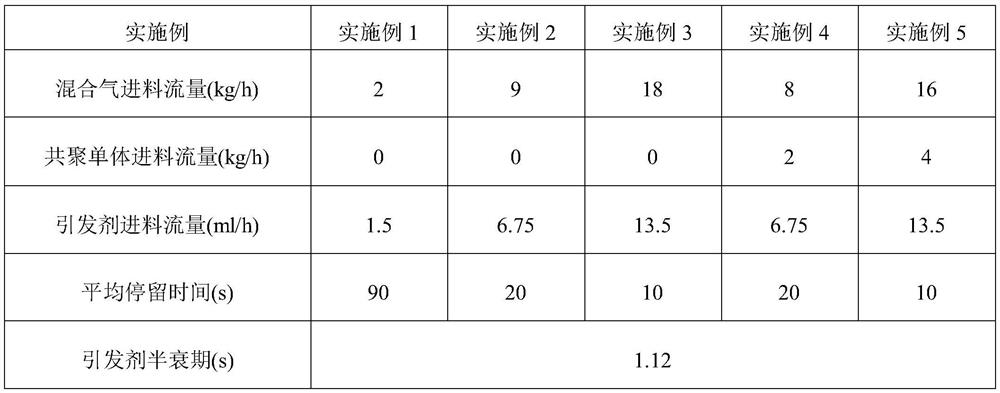

Embodiment 1-5

[0030] Ethylene and ethane are uniformly mixed in the gas distribution tank with a mass flow ratio of 0.98:0.02. The mixed gas is pressurized to 2000bar by a multi-stage compressor, and vinyl acetate is injected into the 50°C premix tank through a diaphragm metering pump. At the same time, TBPB is Isododecane is configured as a solvent to form an initiator solution with a mass concentration of 25%, which is introduced into the premix tank through a syringe pump, and the mass fraction of effective oxygen content in the reaction system is controlled to be 2.5×10 -5 . The reaction kettle has a volume of 0.1 L, and the reaction is carried out at a temperature of 250° C. and a pressure of 2000 bar, and the reaction time is 1 h. The feed flow rate of each component adopts the conditions shown in Table 1 below.

[0031] Under the experimental conditions of this example, the density of ethylene is about 500kg / m 3 , the density of vinyl acetate is about 1000kg / m 3 , The specific hea...

Embodiment 1

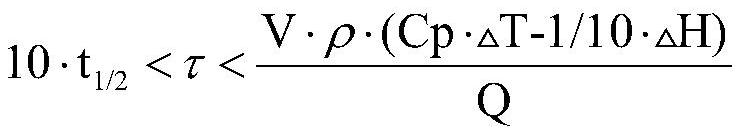

[0036] Taking Example 1 as an example,

[0037] Calculated according to the experimental conditions of this embodiment, the range of the average residence time needs to be kept at 11.2<τ<60s.

[0038] (according to 10·t 1 / 2 Available )

Embodiment 2

[0039] In Example 2 and Example 4, during the reaction process of 1 hour, polyethylene and its copolymer were successfully prepared, and no abnormal phenomenon occurred. In Example 1, during the reaction process of 1 hour, after the reaction was carried out for 30 minutes, an abnormal temperature rise was detected in the kettle. After the reaction was stopped, the situation in the kettle was checked, and it was found that there were some polymers sticking to the wall. During the reaction process of Example 3 and Example 5, an abnormal temperature rise was detected at the pipeline from the outlet to the storage tank at the initial stage of the reaction. The reason was that the residual amount of the initiator in the outlet material was too high, and there was still a reaction in the pipeline. Keep exothermic.

[0040] By strictly controlling the average residence time of the reactor, the present invention avoids excessive residual undecomposed initiator in the outlet material c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com