Method for preparing acrylic thick plate through water bath cooling

An acrylic and water bath technology, which is applied in applications, flat products, household appliances, etc., can solve the problems of insufficient toughness and light transmission, which affect the use of acrylic products, and achieve good electrical insulation, mechanical strength, and good transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method of the present invention will be further described below in conjunction with the examples, but the present invention is not limited thereto.

[0020] A method for preparing acrylic thick plates by cooling in a water bath, characterized in that: the steps include:

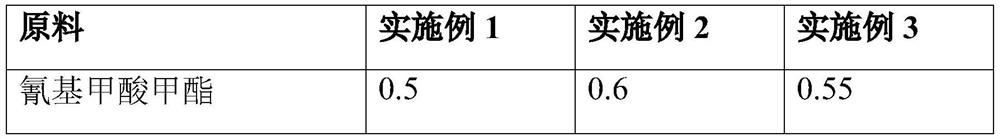

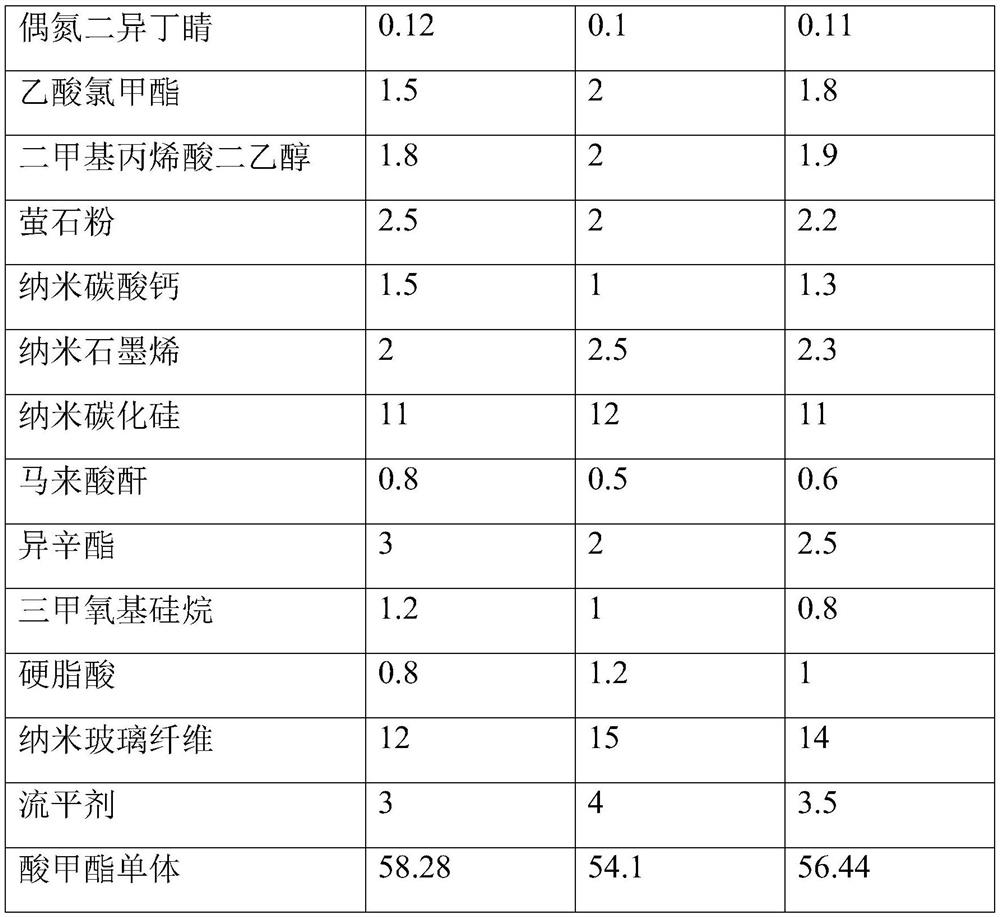

[0021] 1) Pre-polymerization pulping: Add methyl cyanoformate, chloromethyl acetate, diethyl alcohol dimethacrylate, azobisisobutyronitrile, isooctyl ester, and methyl methacrylate monomers into the reactor, Heat to keep the temperature at 100-110°C, increase the pressure to 1MPA, and stir for 1-2 hours; mix fluorite powder, nano-calcium carbonate, nano-graphene, nano-silicon carbide, maleic anhydride, trimethoxysilane, stearic acid, and nano-glass Add fiber and leveling agent into the reaction kettle, and stir continuously for at least 2 hours at 150-160°C and 3-5MPa pressure;

[0022] 2) Degassing: after the reaction is finished, put it into a degassing tank for vacuuming and degassing;

[0023...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap