Preparation process of LMPET/PET sheath-core type composite elastic fiber

A composite elastic fiber and preparation technology, applied in fiber processing, filament/thread forming, conjugated synthetic polymer artificial filament, etc., can solve the problem of increasing spinning difficulty, crystallization performance, thermal stability and melt fluidity Change and other problems, to achieve the effect of easy replacement and maintenance, good laminar flow, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

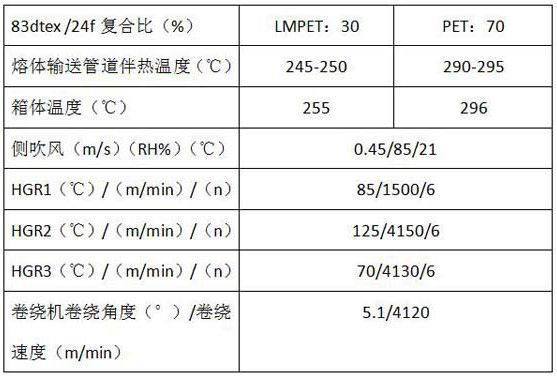

[0028] A kind of LMPET / PET sheath-core type composite elastic fiber preparation process of the present invention, it comprises the following steps,

[0029] (1) Transport the LMPET melt and PET melt to the composite spinning box through the melt delivery pipeline and the metering pump respectively, and install a filter and a booster pump on the melt delivery pipeline, wherein the LMPET melt delivery pipeline is heated The temperature is controlled at 246°C, the heating temperature of the PET melt conveying pipeline is controlled at 292°C, and the composite spinning box includes LMPET spinning box, PET spinning box and spinning component box, and the temperature of LMPET spinning box is 255°C. The temperature of the PET spinning box is 296°C;

[0030] (2) Extrusion through skin-core spinneret, cooling by side blowing, cluster oiling, pre-netting, drafting, netting, and winding. The drafting includes three hot rollers, which are HGR1 and HGR2 respectively And HGR3, the temperat...

Embodiment 2

[0038] A kind of LMPET / PET sheath-core type composite elastic fiber preparation process of the present invention, it comprises the following steps,

[0039] (1) The LMPET melt and PET melt are transported to the composite spinning box through the melt delivery pipeline and the metering pump respectively, and a filter and a booster pump are installed on the melt delivery pipeline, and the LMPET melt delivery pipeline is heated The temperature is controlled at 248°C, the heating temperature of the PET melt conveying pipeline is controlled at 293°C, and the composite spinning box includes LMPET spinning box, PET spinning box and spinning component box, and the temperature of LMPET spinning box is 255°C. The temperature of the PET spinning box is 296°C;

[0040] (2) Extrusion through skin-core spinneret, side blowing cooling, cluster oiling, pre-netting, drafting, netting, and winding. The drafting includes three hot rollers, which are HGR1 and HGR2 respectively And HGR3, the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com