Acetamiprid microcapsule suspending agent

A microcapsule suspension, acetamiprid technology, applied in the direction of insecticides, biocides, animal repellents, etc., can solve the problems of long-term residual time of pesticides, high toxicity, environmental hazards, etc., and achieve excellent controlled release and slow Effects of release performance and excellent formulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

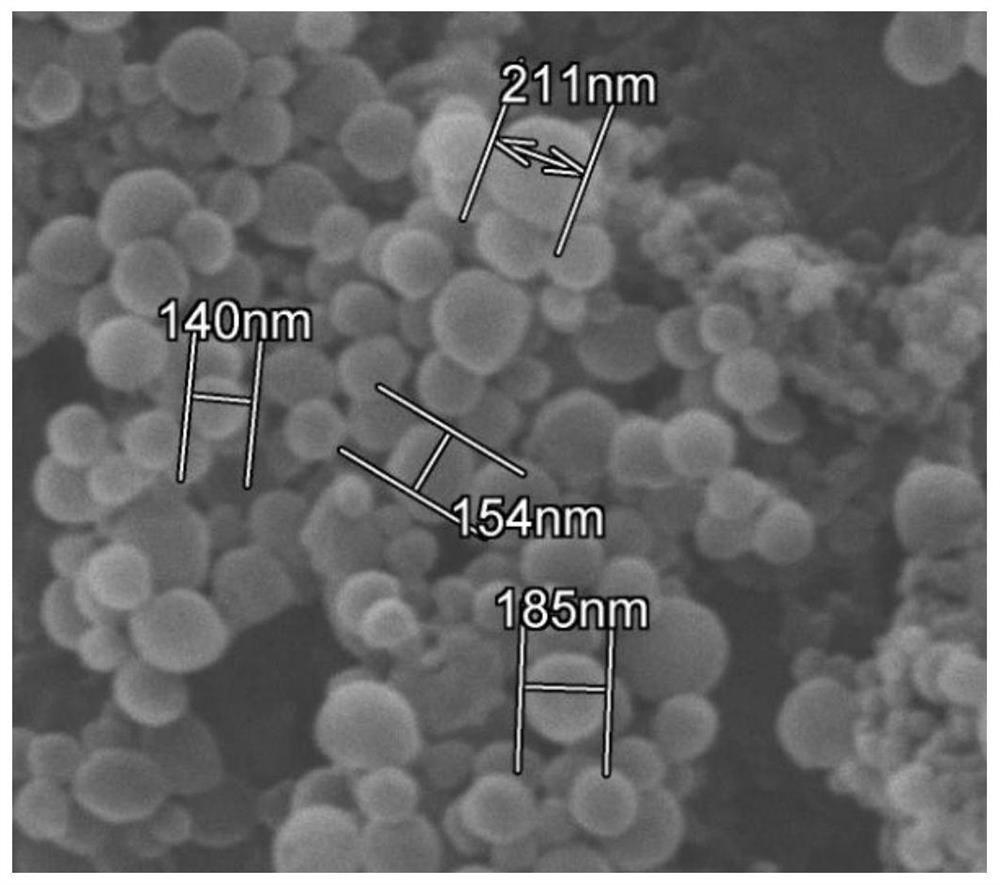

[0038] Example 1 5% acetamiprid microcapsule suspension

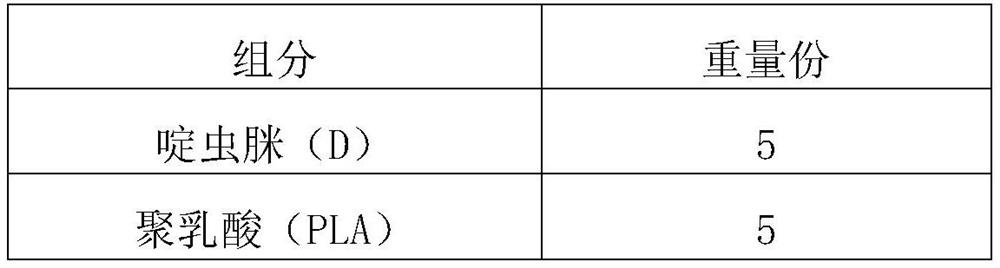

[0039] Table 1 5% acetamiprid microcapsule suspension formula

[0040] components parts by weight Acetamiprid (D) 5 Polylactic acid (PLA) 5 Polyvinyl alcohol (PVA) 1.5 1,4-dioxane 20 Alkylphenol polyoxyethylene ether phosphate 3 Farm milk 500 2 Sodium naphthalenesulfonate formaldehyde condensate 2 Ethylene glycol 3 Silicone 2 xanthan gum 1.5 Deionized water Make up 100 copies

[0041] Preparation method: first prepare D solution, PLA solution, and PVA solution respectively: stir and dissolve D with a certain amount of 1,4-dioxane; add PLA to a certain amount of 1,4-dioxane, and magnetic stirrer 90°C, 900rpm, until dissolved; add PVA to a certain amount of deionized water, stir and dissolve in a 90°C water bath. Secondly, after fully mixing D solution and PLA solution by ultrasonic vibration, stir in a magnetic stirrer at 300rpm, quickly ...

Embodiment 2

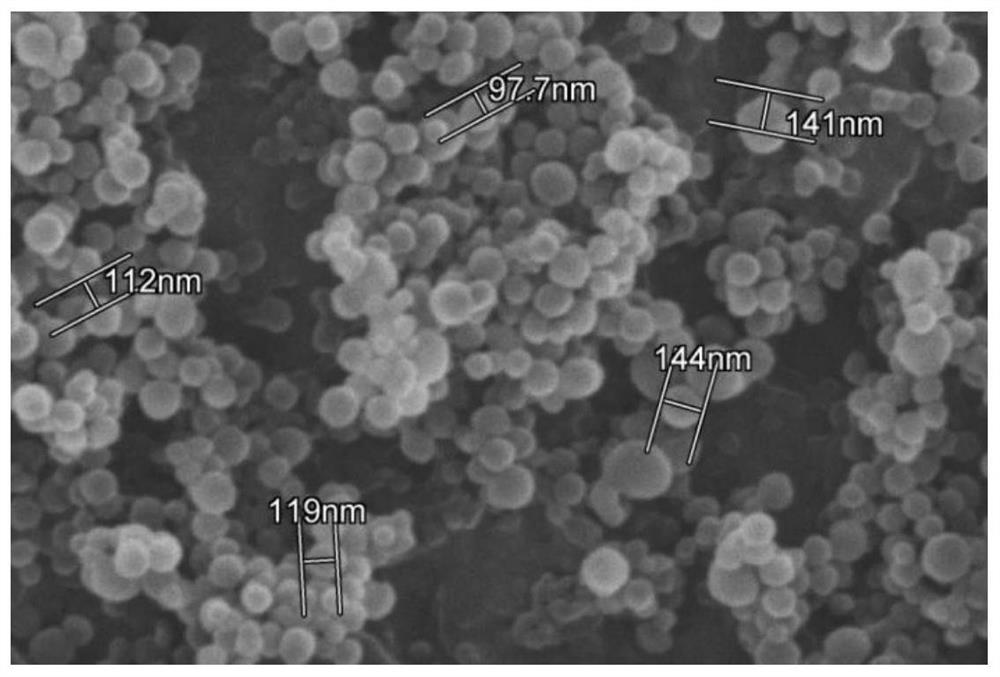

[0042] Example 2 1.5% acetamiprid microcapsule suspension

[0043] Table 2 1.5% acetamiprid microcapsule suspension formula

[0044] components parts by weight Acetamiprid (D) 1.5 Polylactic acid (PLA) 1 Polyvinyl alcohol (PVA) 1 1,4-dioxane 15 Sodium dodecyl sulfate 1.5 Farm milk 600 3 Sodium naphthalenesulfonate formaldehyde condensate 2 Propylene Glycol 3 Silicone 1.5 carboxymethyl cellulose 1 Deionized water Make up 100 copies

[0045] Preparation method: first prepare D solution, PLA solution, and PVA solution respectively: stir and dissolve D with a certain amount of 1,4-dioxane; add PLA to a certain amount of 1,4-dioxane, and magnetic stirrer 90°C, 900rpm, until dissolved; add PVA to a certain amount of deionized water, stir and dissolve in a 90°C water bath. Secondly, after fully mixing D solution and PLA solution by ultrasonic vibration, stir in a magnetic stirrer at 300rpm, quickly po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com