Preparation method of pressureless sintering micro-nano mixed silicon carbide granulated powder

A technology of micro-nano mixing and silicon carbide, which is applied in the field of preparation of silicon carbide granulated powder, can solve the problems of inability to achieve uniform dispersion and easy agglomeration of nanoparticles, and achieve good dispersion effect, safe preparation process and low risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] Specific embodiment one: the present embodiment is a kind of preparation method of pressureless sintering micro-nano mixed silicon carbide granulated powder, it is carried out according to the following steps:

[0033] 1. Powder pretreatment:

[0034] The silicon carbide micropowder, silicon carbide nanopowder and sintering aid are respectively placed in an oven and dried at a constant temperature to obtain pretreated silicon carbide micropowder, pretreated silicon carbide nanopowder and pretreated sintering aid;

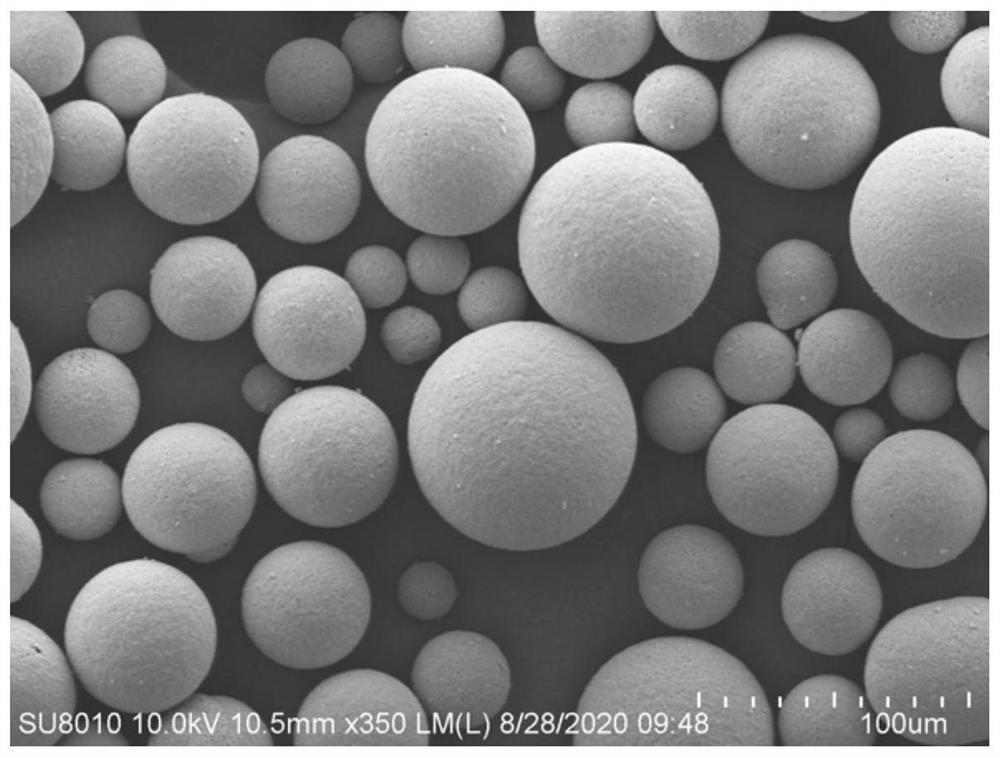

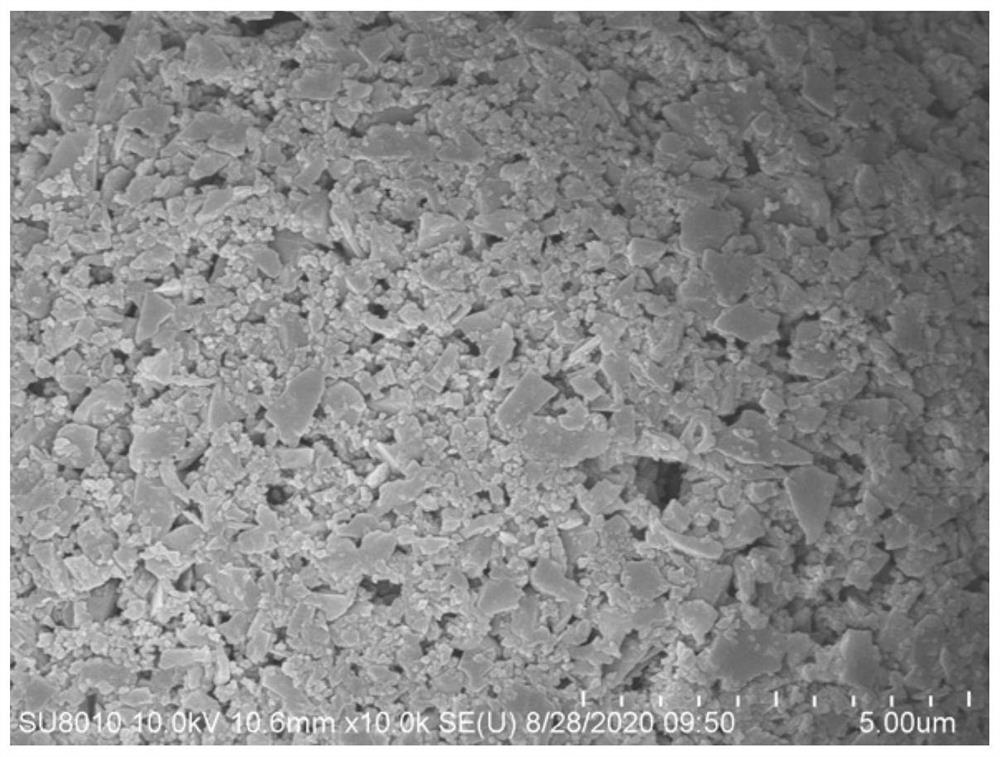

[0035] The particle size of the silicon carbide micron powder is 0.3 μm to 10 μm; the particle size of the silicon carbide nano powder is 1 nm to 200 nm;

[0036] 2. High energy processing:

[0037] The pretreated silicon carbide nanopowder is blended with a surfactant, then spread flat, and subjected to surface modification treatment for 5s to 1200s under the irradiation conditions of infrared light, ultraviolet light or electromagnetic waves with a frequen...

specific Embodiment approach 2

[0057] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the sintering aid described in step 1 is a mixture of one or more of carbon, boron and boron carbide; the constant temperature described in step 1 Drying is carried out at a drying temperature of 60° C. to 120° C. for 2 hours to 24 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0058] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the surfactant described in step two is a kind of in silane coupling agent, N-acyl glutamate and polycarboxylate or a mixture of several of them. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com