On-site metallographic film-coated test paper and preparation method and use method thereof

A technology of test paper and coating, which is applied in the field of on-site metallographic coating test paper, can solve the problems of easy explosion, acute/chronic poisoning, and easy production of poison, and achieve the effects of improving production efficiency, no toxic side effects, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

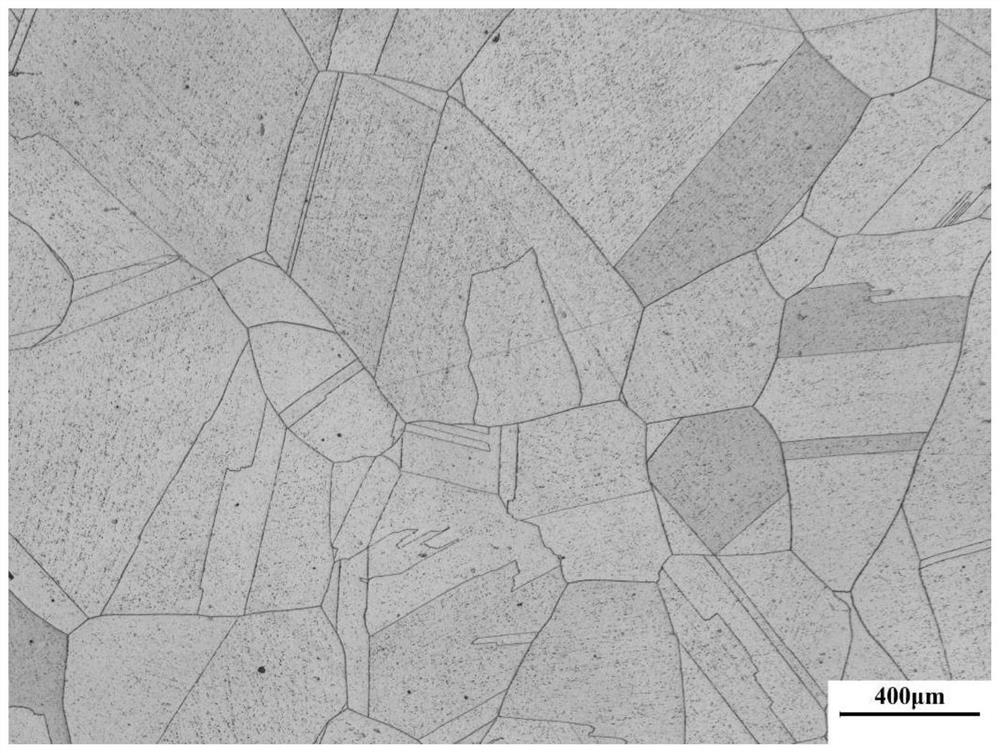

[0027] Sample selection of a nickel-based alloy

[0028] Formulation of coated test paper:

[0029] Ethylcellulose 40g

[0030] Methyl violet 0.5g

[0031] Absolute ethanol 500mL

[0032] Put absolute ethanol in the container at room temperature, add ethyl cellulose and methyl violet in sequence while stirring, and stir with a magnetic stirrer for 2 to 3 hours, after the ethyl cellulose and methyl violet are completely dissolved Let it stand for more than one day, so that the bubbles in the solution float up and the impurities sink, then pour the upper layer of clean solution into a dry and clean bottle, and skim off the lower layer of impurity solution for use.

[0033] Pour the prepared clean solution on a clean, flat and non-scratched surface. After paving, adjust the surface of the plate, cover the plate, and let it dry. After the ethanol evaporates, remove the test paper on the plate.

[0034] Sample processing procedure: coarse grinding→fine grinding→coarse polishing...

Embodiment 2

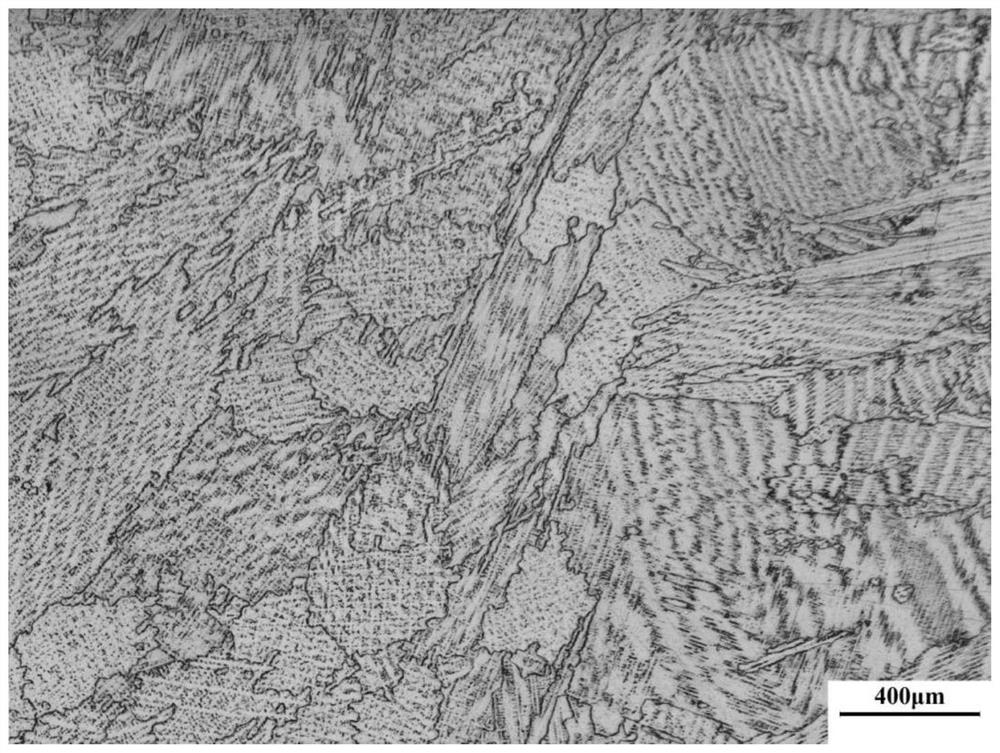

[0036] The sample is selected from a nickel-based alloy butt weld

[0037] Formulation of coated test paper:

[0038] Ethyl cellulose 50g

[0039] Methyl violet 0.1g

[0040] Absolute ethanol 500mL

[0041] Put absolute ethanol in the container at room temperature, add ethyl cellulose and methyl violet in sequence while stirring, and stir with a magnetic stirrer for 2 to 3 hours, after the ethyl cellulose and methyl violet are completely dissolved Let it stand for more than one day, so that the bubbles in the solution float up and the impurities sink, then pour the upper layer of clean solution into a dry and clean bottle, and skim off the lower layer of impurity solution for use.

[0042] Pour the prepared clean solution on a clean, flat and non-scratched surface. After paving, adjust the surface of the plate, cover the plate, and let it dry. After the ethanol evaporates, remove the test paper on the plate.

[0043] Sample processing procedure: coarse grinding→fine grindi...

Embodiment 3

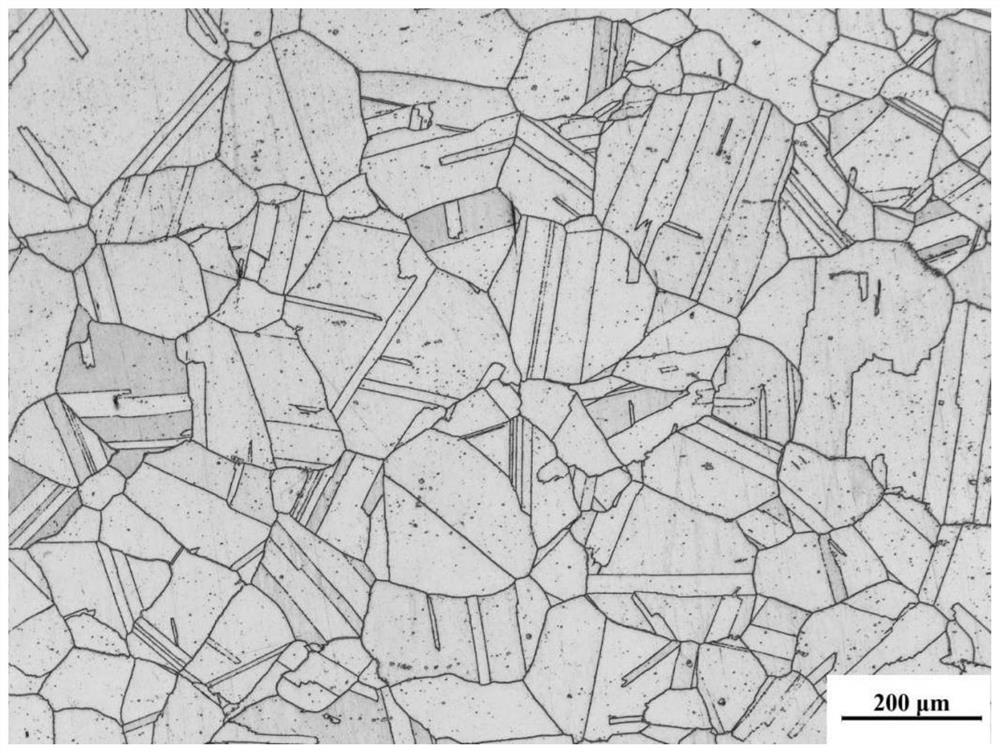

[0045] The sample selection material is a nickel-based alloy.

[0046] Formulation of coated test paper:

[0047] Ethyl cellulose 80g

[0048] Methyl violet 0.1g

[0049] Absolute ethanol 500mL

[0050] Put absolute ethanol in the container at room temperature, add ethyl cellulose and methyl violet in sequence while stirring, and stir with a magnetic stirrer for 2 to 3 hours, after the ethyl cellulose and methyl violet are completely dissolved Let it stand for more than one day, so that the bubbles in the solution float up and the impurities sink, then pour the upper layer of clean solution into a dry and clean bottle, and skim off the lower layer of impurity solution for use.

[0051] Pour the prepared clean solution on a clean, flat and non-scratched surface. After paving, adjust the surface of the plate, cover the plate, and let it dry. After the ethanol evaporates, remove the test paper on the plate.

[0052] Sample processing procedure: coarse grinding→fine grinding→c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com