Extrusion production method of stony phosphogypsum product

A production method and technology of phosphogypsum, which is applied in the field of solid waste resource utilization and prefabricated building materials, can solve the problems of low strength, poor water resistance, and low proportion of gypsum, and achieve low preparation cost, easy preparation, and flexible production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

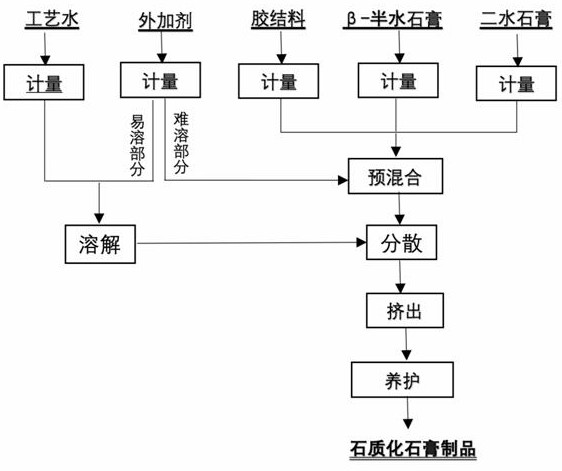

Method used

Image

Examples

Embodiment 1

[0036] Based on the total batching mass of 500kg, the amount of gypsum accounts for 96% of the main material mass, and the total weight of β-hemihydrate gypsum and dihydrate gypsum is 480kg according to the mass ratio of 1:3, and 20 kg of ordinary Portland P.I42.5 cement accounts for Ratio of 4%, respectively sent to the activated stirring tank by screw conveyor, and at the same time, add seeds according to the following ingredients: the sum of the addition amount of α gypsum seeds and the seeds prepared by the consolidated body is 0.4% of the mass of the main material ‰, the mass ratio of the two is 1:1, and the mass proportion of the added α-gypsum seeds with a particle size of less than 38 μm is 95%, and the mass proportion of the seeds with a particle size of less than 38 μm in the consolidated body is 97%; The consolidated body is obtained by cementing with the label P.I42.5. Weigh 250kg of process water according to the water-cement ratio of 0.50, and weigh 0.1kg of sodiu...

Embodiment 2

[0038] Based on the total batching mass of 500kg, the amount of phosphogypsum accounts for 91% of the mass of the main material, and the total weight of β-hemihydrate gypsum and dihydrate gypsum is 455kg according to the mass ratio of 1:0.5, and 45kg of ordinary portland cement clinker accounts for 9 %, respectively sent to the activated stirring tank by the screw conveyor, and at the same time add the crystal seeds according to the following ingredients: the sum of the addition amount of the α gypsum crystal seeds and the seeds prepared by the consolidated body is 0.6‰ of the mass of the main material, The mass ratio of the two is 1:1, and the mass of the added α-gypsum seeds with a particle size of less than 38 μm accounts for 98%, and the mass of the seeds prepared by the consolidated body has a particle size of less than 38 μm accounts for 97%; The consolidated body is obtained by solidifying clinker slurry; weigh 200kg of process water according to the water-cement ratio o...

Embodiment 3

[0040] Based on the total batching mass of 500kg, the amount of gypsum accounts for 93% of the mass of the main material, weighing 465kg of hemihydrate gypsum and dihydrate gypsum according to the mass ratio of 1:1, and 35kg of ordinary portland cement clinker accounting for 7%, respectively Send it into the agitated tank that has been started by a screw conveyor, and add seeds according to the following ingredients at the same time: the sum of the addition amount of α-gypsum seeds and the seeds prepared by the consolidated body is 0.2‰ of the mass of the main material, and the mass of the two The ratio is 1:1, and the mass of the added α-gypsum seed crystals with a particle size less than 38 μm accounted for 98%, and the mass of the seed crystals prepared by the consolidated body accounted for 95%; the consolidated body Obtained from clinker net slurry consolidation; Weigh 225kg of process water according to the water-cement ratio of 0.45, weigh the main material 0.2‰ sodium l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com