Nursing product water-based printing ink and preparation method thereof

A technology for nursing products and printing inks, applied in the field of functional polymers, can solve the problems of manufacturers and merchants who dare not make reasonable inventory, passive loss of economic benefits due to shortage of stock, short shelf life of diaper products, etc., to meet market environmental protection and high-end exquisite printing. , Improve product shelf life and ensure the effect of ink printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

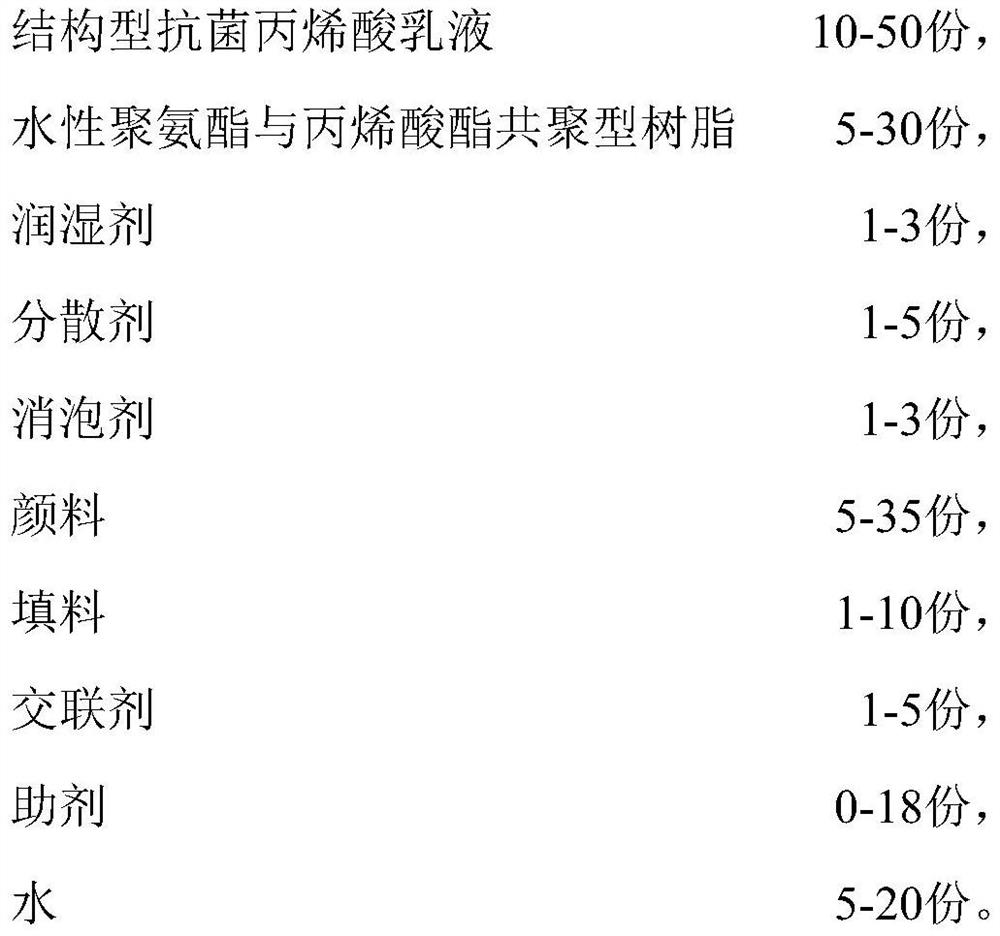

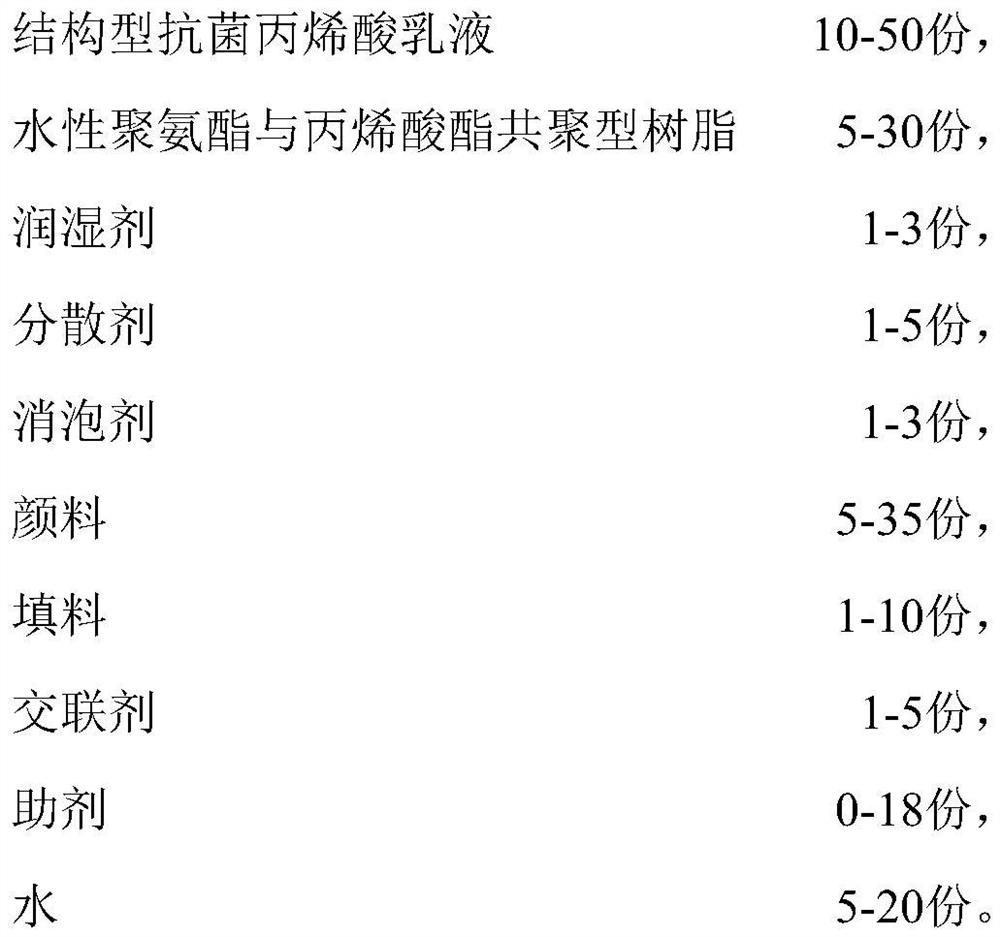

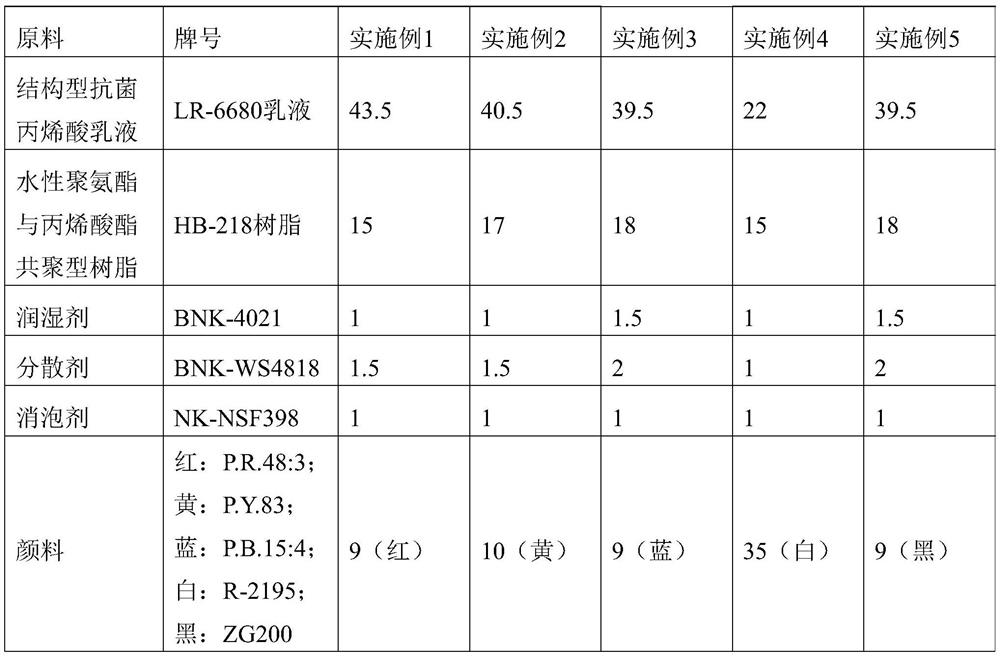

[0042] The present embodiment provides a water-based printing ink for care products, comprising the following raw material components in parts by weight:

[0043] 43.5 parts of structural antibacterial acrylic emulsion, 15 parts of water-based polyurethane and acrylate copolymer resin, 1 part of wetting agent, 1.5 parts of dispersing agent, 1 part of defoamer, 9 parts of pigment, 5 parts of filler, 2 parts of crosslinking agent, 3 parts of disinfectant, 2 parts of wax emulsion, 3 parts of adhesion promoter, 2 parts of anti-blocking agent, 8 parts of deionized water.

[0044] The structural antibacterial acrylic emulsion is LR-6680 antibacterial emulsion produced by Guangdong Henghe Yongsheng Industrial Co., Ltd. The waterborne polyurethane and acrylic acid copolymer resin is HB-218 resin produced by Zhongshan Huijute New Material Co., Ltd. The wetting agent is BNK-4021 fluorocarbon surfactant; the dispersant is BNK-WS4818 water-based hyperdispersant; the defoamer is NK-NSF398...

Embodiment 2

[0054] The present embodiment provides a water-based printing ink for care products, comprising the following raw material components in parts by weight:

[0055] 40.5 parts of structural antibacterial acrylic emulsion, 17 parts of water-based polyurethane and acrylate copolymer resin, 1 part of wetting agent, 1.5 parts of dispersing agent, 1 part of defoamer, 10 parts of pigment, 4 parts of filler, 2 parts of crosslinking agent, 3 parts of disinfectant, 2 parts of wax emulsion, 3 parts of adhesion promoter, 2 parts of anti-blocking agent, 8 parts of deionized water.

[0056] In this embodiment, the pigment is the P.Y.83 yellow pigment of BASF; the rest of the raw material components are the same as in Example 1.

[0057] A preparation method of water-based printing ink for nursing products, comprising the following steps:

[0058] (1) Pre-mix the disinfectant solution, 30% deionized water of the total amount and 30% of the filler of the total amount and let it stand for more...

Embodiment 3

[0064] The present embodiment provides a water-based printing ink for care products, comprising the following raw material components in parts by weight:

[0065] 39.5 parts of structural antibacterial acrylic emulsion, 18 parts of water-based polyurethane and acrylate copolymer resin, 1.5 parts of wetting agent, 2 parts of dispersing agent, 1 part of defoamer, 9 parts of pigment, 5 parts of filler, 1 part of crosslinking agent, 4 parts of disinfectant, 3 parts of wax emulsion, 3 parts of adhesion promoter, 2 parts of anti-blocking agent, 10 parts of deionized water.

[0066] In this embodiment, the pigment is the P.B.15:4 blue pigment of BASF of BASF, the filler is calcium carbonate with a fineness≤3000 μm, and the disinfectant is CHANGHUI-DISI003 produced by Shenzhen Changhui Company Disinfectant, the adhesion promoter is a BNK-6065 accelerator; all the other raw material components are the same as in Example 1.

[0067] A preparation method of water-based printing ink for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com