Separated heating wide-range oxygen sensor

An oxygen sensor, a separate technology, applied in the field of high-precision wide-area sensors, can solve the problems of difficult to control the consistency of sintering shrinkage, small diffusion cavities and ceramic cracks, and current easily polluted or interfered. , to enhance the overall reliability, the effect of high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0039] technical features

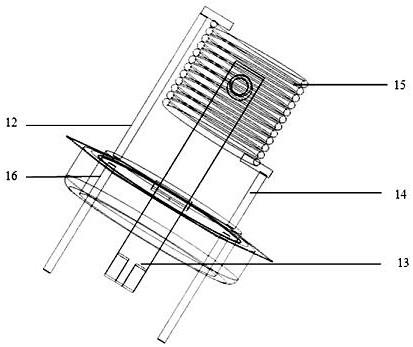

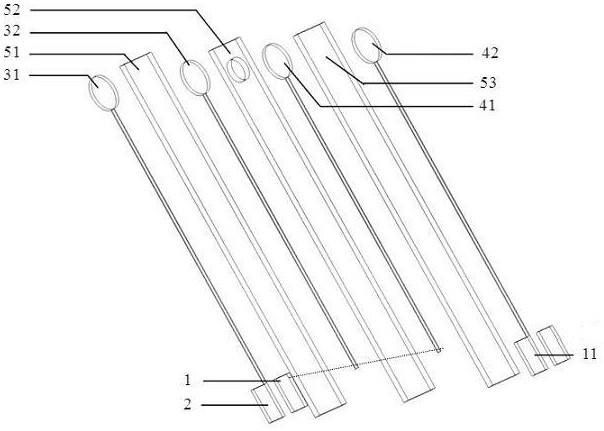

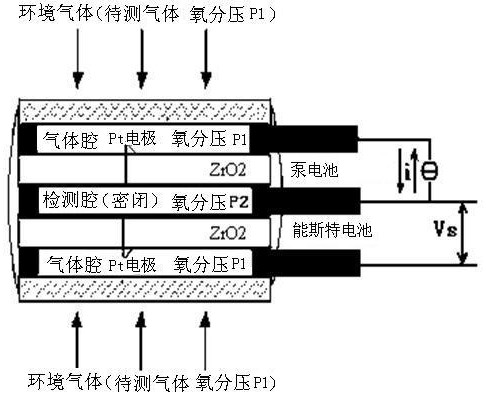

[0040] The novel high-precision wide-range oxygen sensor of the invention belongs to the oxygen sensor based on zirconia. Unlike most wide-area oxygen sensors, it has an external heater, no diffusion barrier flow-limiting design, and does not require a reference gas, and can be automatically tested and recalibrated in normal ambient air. The accuracy of oxygen measurement is as high as 4%, and the range of oxygen measurement is ultra-wide (l=0.1~∞). The oxygen sensor in this invention uses a zirconia ceramic substrate, referred to as a zirconium plate. The heater is made of iron chromium alloy.

[0041] Technical solutions

[0042] 2.1 Sensor design

[0043] 2.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com