A rapid pretreatment method for detecting monoalcohol tetraesters in fermented grains

A technology of pretreatment and fermented grains, applied in the field of winemaking, can solve the problems of low sample detection accuracy, complex operation process of pretreatment technology, and long cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

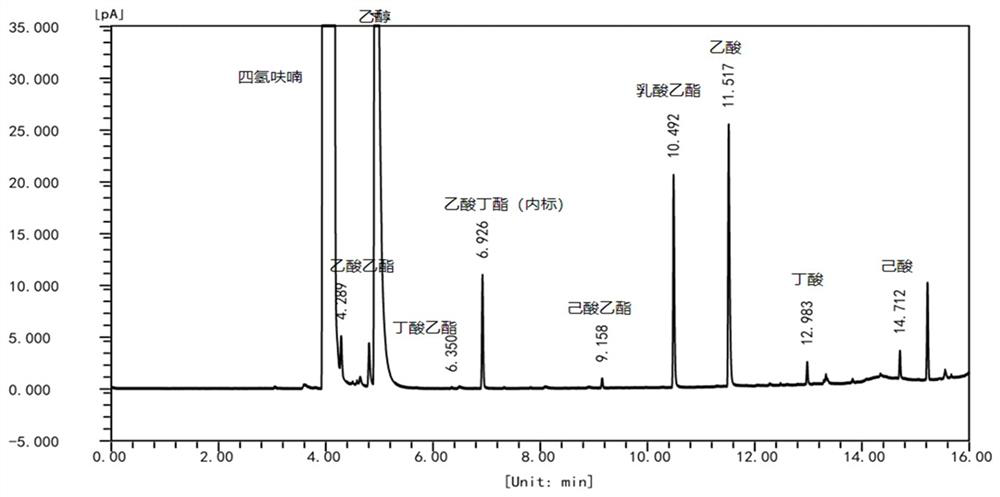

[0024] Take 12 parts of cellar distiller's grains with a weight of 5 g that have been fermented for 90 days and mixed uniformly in 12 centrifuge tubes, and each 3 centrifuge tube samples are used as a group, a total of 4 groups, and each group is added with different extraction agents tetrahydrofuran, ethanol, After 20ml of ethyl acetate and chloroform, seal it with plastic wrap and let it stand for 15 minutes ( figure 1 It is a graphical representation of the color change of the extraction solution after adding four different extraction solutions to the distiller's grain sample in Example 1 and standing for 15 minutes. It can be seen from the figure that the color of the extraction solution is tetrahydrofuran, ethanol, and ethyl acetate from dark to light. esters and chloroform, which indirectly shows that the tetrahydrofuran extraction solution has a better infiltration effect on distiller's grain samples than other extraction solutions. ), then centrifuge the centrifuge tub...

Embodiment 2

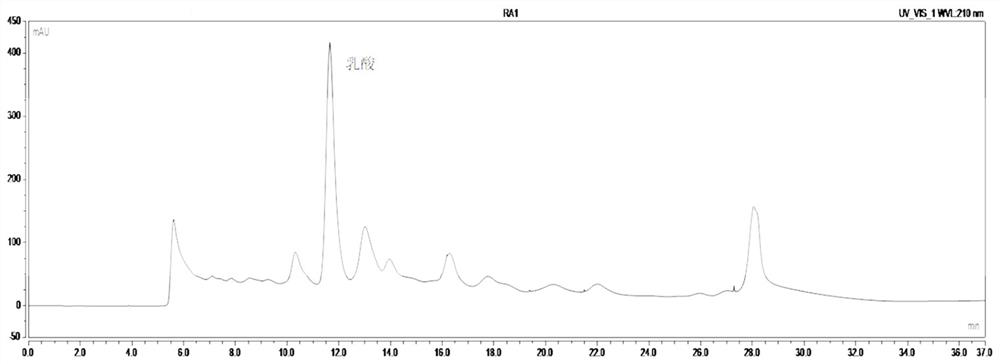

[0033] Take 6 parts of 5g cellar distiller's grains that have been fermented for 90 days and have been mixed uniformly in 6 centrifuge tubes, and each 3 centrifuge tube samples are taken as a group, a total of 2 groups. After adding 20ml of tetrahydrofuran to each centrifuge tube, seal the junction of the centrifuge tube cap and the tube body with plastic wrap and place it on the centrifuge tube stand for 10 minutes, 15 minutes and 30 minutes respectively. After centrifugation at 10,000 rpm for 5 minutes, take 5ml of the supernatant in a 25ml centrifuge tube and use the same solvent as the extraction agent to make up the volume. Take 10ml of the liquid after the volume down and add 5g of anhydrous magnesium sulfate in advance. After putting in the 50ml centrifuge tube, seal the junction of the centrifuge tube cap and the tube body with plastic wrap, and place it on the centrifuge tube stand for about 45 minutes, then filter it with a 0.22 micron organic filter membrane, and con...

Embodiment 3

[0039] Take 9 portions of 5g of problem cellar distiller's grains that have been fermented for 90 days and mixed uniformly in 9 centrifuge tubes, and each 3 centrifuge tube samples are taken as a group, a total of 3 groups. After adding 20ml of tetrahydrofuran to each centrifuge tube, seal the junction of the centrifuge tube cap and the tube body with plastic wrap and place it on the centrifuge tube stand for 15 minutes. Centrifuge for 5 minutes under the same conditions, filter through qualitative filter paper, and take vacuum filtration. After the operation, take 5ml of supernatant in 25ml centrifuge tubes and use the same solvent as the extraction agent to fix the volume. After adding 5g of anhydrous magnesium sulfate into a 50ml centrifuge tube, seal the junction of the centrifuge tube cap and the tube body with plastic wrap, and place it on a centrifuge tube stand for about 45 minutes before filtering with a 0.22 micron organic filter membrane , the obtained clear liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com