Production method of anti-mildew and anti-sticking feed

A production method and feed technology applied in the field of anti-mildew and anti-sticking feed, which can solve the problems of energy consumption, loss of fermented soybean meal, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

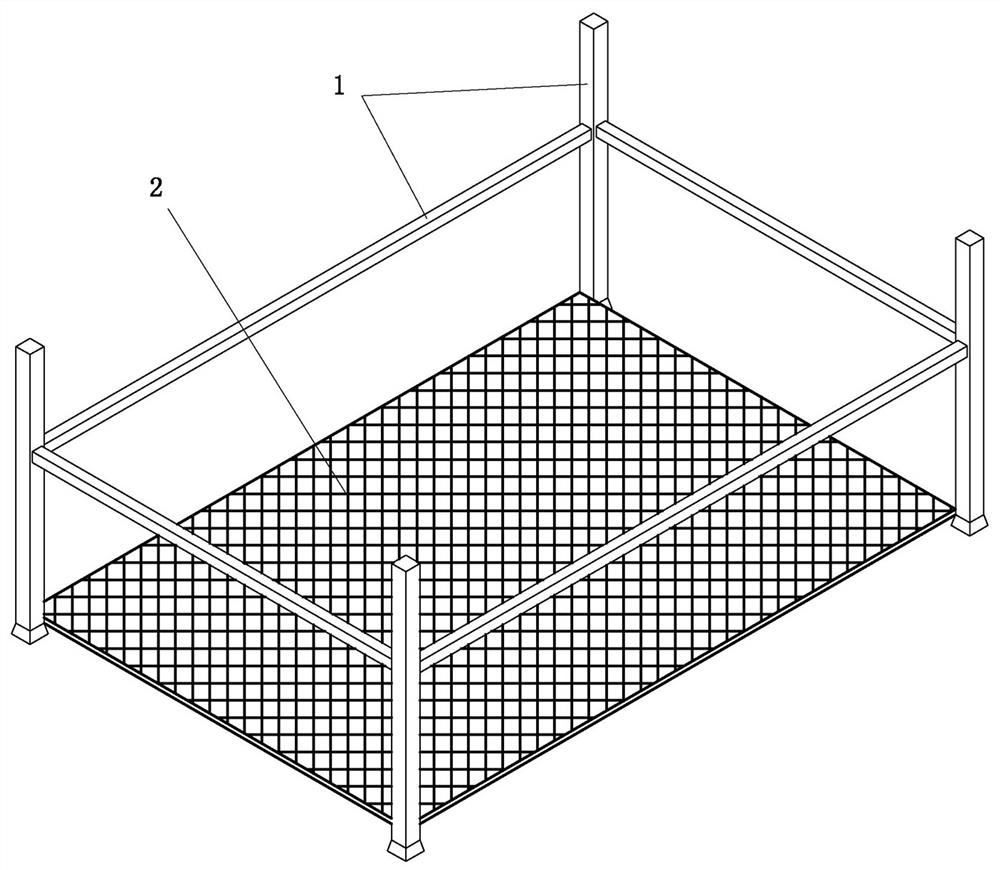

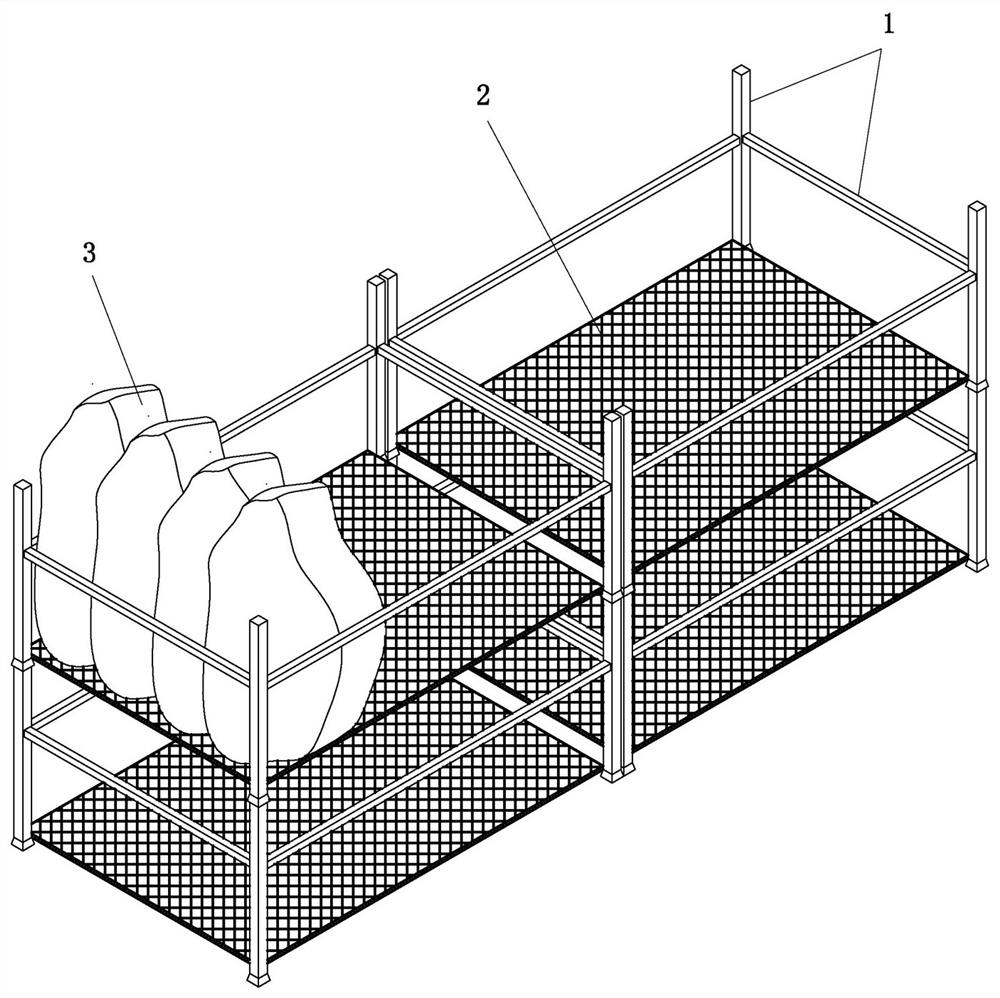

Image

Examples

Embodiment 1

[0053] The site was selected for trial operation in Hunan Liangping Biotechnology Co., Ltd., Changsha City, Hunan Province. The soybean meal raw material was obtained from Hunan Liangping Agriculture and Animal Husbandry Development Co., Ltd. Specific steps are as follows:

[0054] S1, preparation bacterial enzyme, concrete operation is as follows:

[0055] 1) Obtain the required fermentation strains: Take 1g each of Baiyunbian distillery koji, vegetable garden soil, and Baiyunbian distillery pit mud in a 100mL Erlenmeyer flask, add PDA medium for enrichment and culture for 12 hours, dilute and spread, pick For a single colony, add 1% milk powder or 1% soluble starch to the plate, and screen the strains with transparent circles around the colonies, which are strains with high protease or amylase production respectively, and its 28ITS DNA is verified as Aspergillus oryzae (MQ) by PCR amplification and sequencing , Aspergillus niger (HQ), yeast (YT) strains.

[0056] 2) Prepar...

Embodiment 2

[0089] The site was selected for trial operation in Hubei Liangping Biological Fermentation Technology Co., Ltd. The raw material of soybean meal was taken from Hubei Liangping Biological Fermentation Technology Co., Ltd. Specific steps are as follows:

[0090] S1, preparation bacterial enzyme, concrete operation is as follows:

[0091] 1) Obtain the required fermentation strains: Take 1g each of Baiyunbian distillery koji, vegetable garden soil, and Baiyunbian distillery pit mud in a 100mL Erlenmeyer flask, add PDA medium for enrichment and culture for 12 hours, dilute and spread, pick For a single colony, add 1% milk powder or 1% soluble starch to the plate, and screen the strains with transparent circles around the colonies, which are strains with high protease or amylase production respectively, and its 28ITS DNA is verified as Aspergillus oryzae (MQ) by PCR amplification and sequencing , Aspergillus niger (HQ), yeast (YT) strains.

[0092] 2) Prepare the medium required...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com