Grouting material prepared from steel slag as well as preparation method and application of grouting material

A grouting material and steel slag technology, applied in the field of grouting material and its preparation, can solve problems such as being unsuitable for large-scale popularization, unsuitable for highly corrosive marine environment, and general corrosion resistance, and achieve good early strength and hydration Speed, self-expansion without shrinkage, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

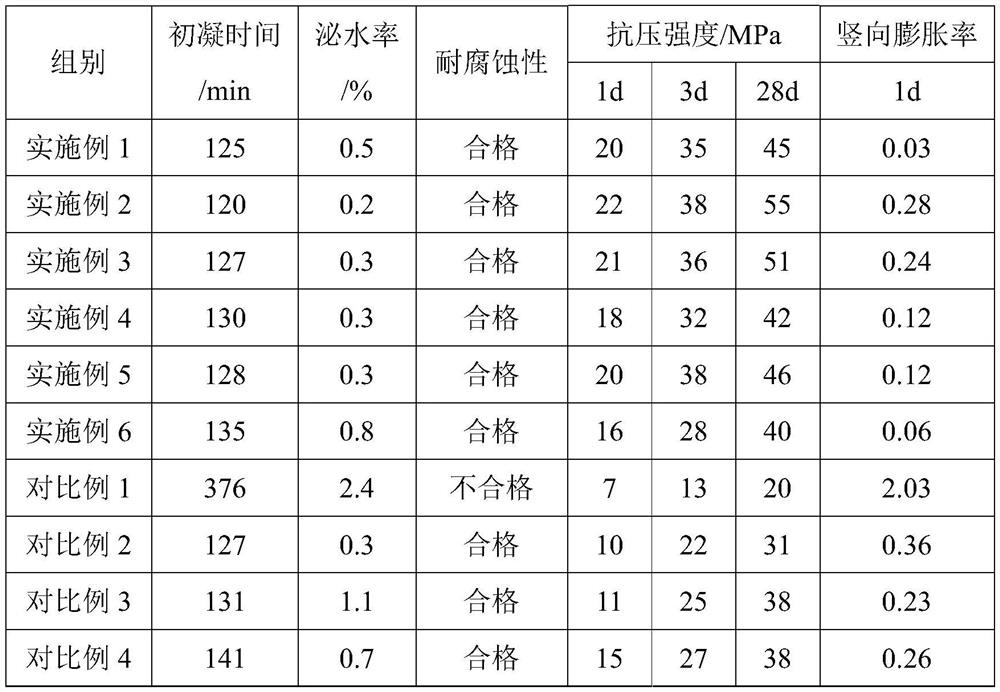

Examples

Embodiment 1

[0048] This embodiment provides a grouting material prepared by using steel slag and its preparation method. In parts by mass, the grouting material includes: 40 parts of steel slag powder, 60 parts of steel slag fine aggregate, 0.1 part of polycarboxylate superplasticizer, 0.2 part of sodium hydroxide as an activator, 0.1 part of a silicone defoamer, and 12 parts of water;

[0049] Described preparation method comprises the steps:

[0050] (1) The steel slag powder is obtained by crushing and grinding the open hearth furnace steel slag, and the specific surface area of the steel slag powder is >400m 2 / kg; open hearth furnace steel slag is crushed, screened and magnetically separated to obtain the steel slag fine aggregate, the particle size of the steel slag fine aggregate is divided into three ranges, respectively 30-50 mesh, 60-80 mesh And 100-120 mesh, and the mass ratio of 30-50 mesh, 60-80 mesh and 100-120 mesh is 1:1:1;

[0051] (2) According to the proportioning b...

Embodiment 2

[0053] This embodiment provides a grouting material prepared by using steel slag and its preparation method. In parts by mass, the grouting material includes: 60 parts of steel slag powder, 40 parts of steel slag fine aggregate, 1 part of polycarboxylate superplasticizer, 5 parts of sodium hydroxide as activator, 1 part of silicone defoamer, 20 parts of water;

[0054] Described preparation method comprises the steps:

[0055] (1) The steel slag powder is obtained by crushing and grinding the converter steel slag, and the specific surface area of the steel slag powder is >400m 2 / kg; the steel slag fine aggregate is obtained after the converter steel slag is crushed, screened and magnetically separated. And 100-120 mesh, and the mass ratio of 30-50 mesh, 60-80 mesh and 100-120 mesh is 1:2:2;

[0056] (2) According to the proportioning by mass, weigh 60 parts of steel slag powder prepared in step (1), 40 parts of steel slag fine aggregate prepared in step (1), 1 part of pol...

Embodiment 3

[0058] This embodiment provides a grouting material prepared by using steel slag and a preparation method thereof. In parts by mass, the grouting material includes: 50 parts of steel slag powder, 50 parts of steel slag fine aggregate, and 0.5 part of lignin superplasticizer, as 2.5 parts of calcium hydroxide as activator, 0.5 parts of polyether defoamer, 16 parts of water;

[0059] Described preparation method comprises the steps:

[0060] (1) The steel slag powder is obtained by crushing and grinding the open hearth furnace steel slag, and the specific surface area of the steel slag powder is >400m 2 / kg; open hearth furnace steel slag is crushed, screened and magnetically separated to obtain the steel slag fine aggregate, the particle size of the steel slag fine aggregate is divided into three ranges, respectively 30-50 mesh, 60-80 mesh And 100-120 mesh, and the mass ratio of 30-50 mesh, 60-80 mesh and 100-120 mesh is 1:1.5:1.5;

[0061] (2) According to the proportionin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com