A preparation method and application of a photoresponsive imprinted material based on magnetic iron ferric oxide nanoparticles

A technology of ferric tetroxide and nanoparticles, applied in chemical instruments and methods, analytical materials, material separation, etc., can solve the problem of difficulty in directly coating the molecularly imprinted polymer layer, achieve good light response performance, increase specificity. Adsorption site, the effect of improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

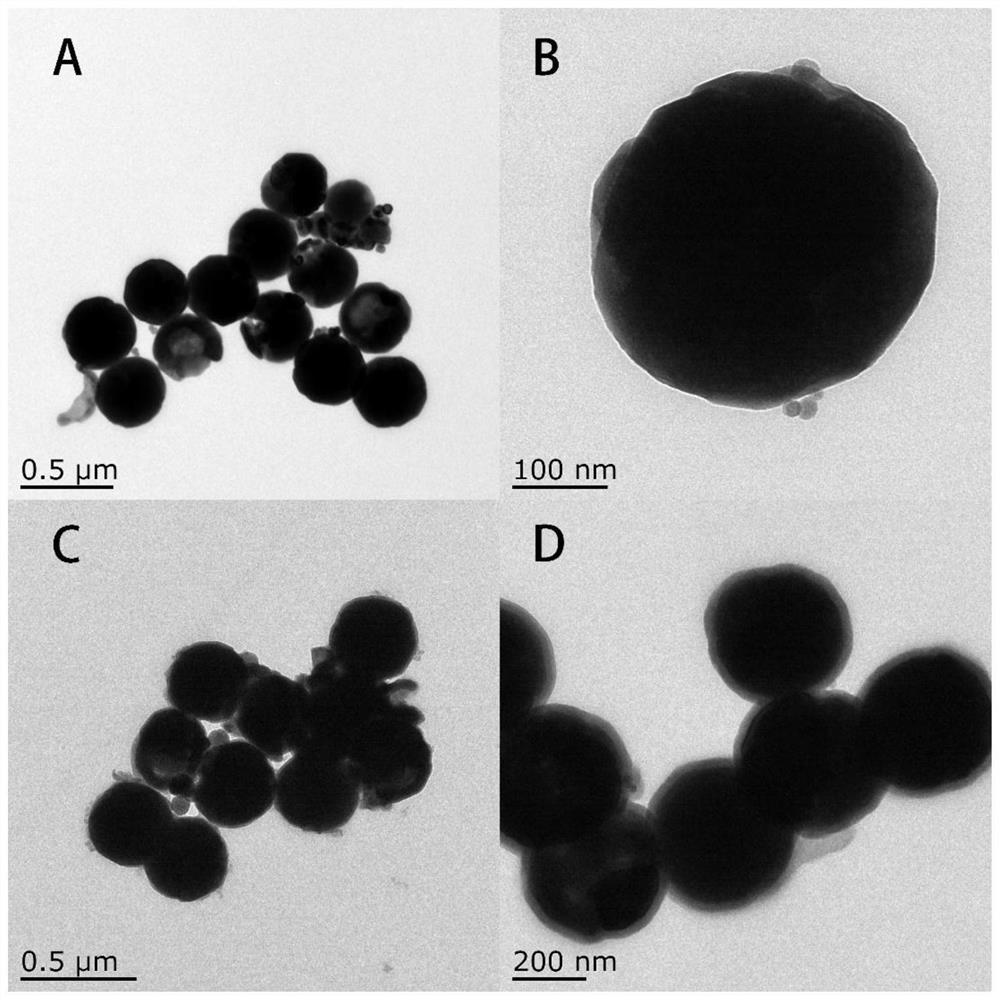

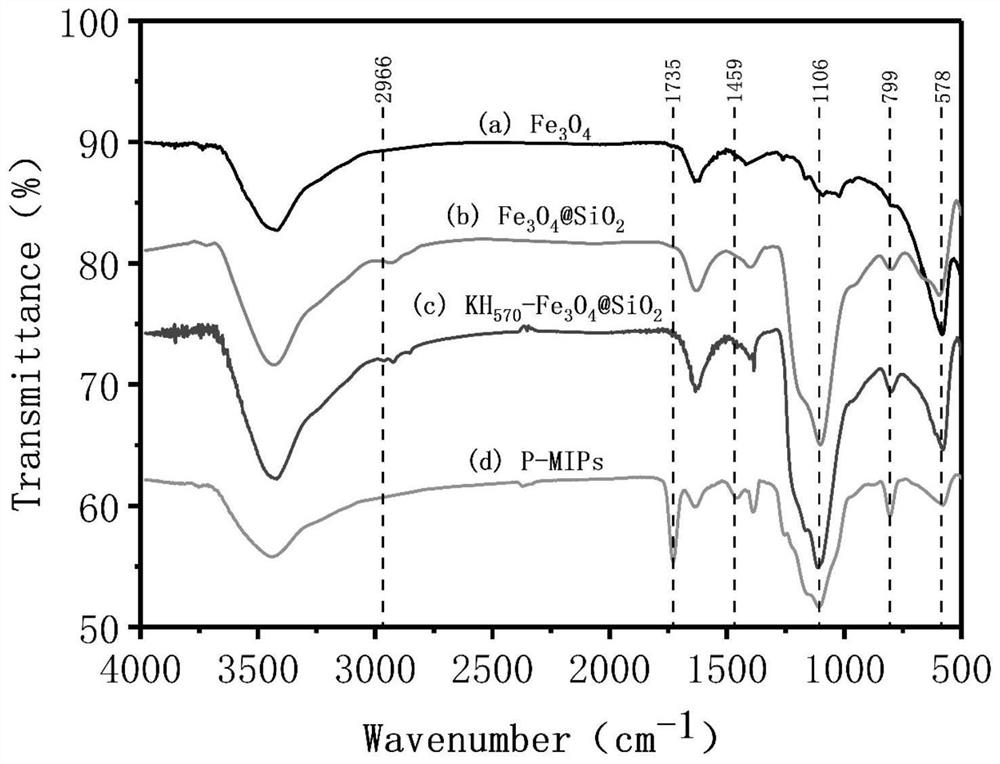

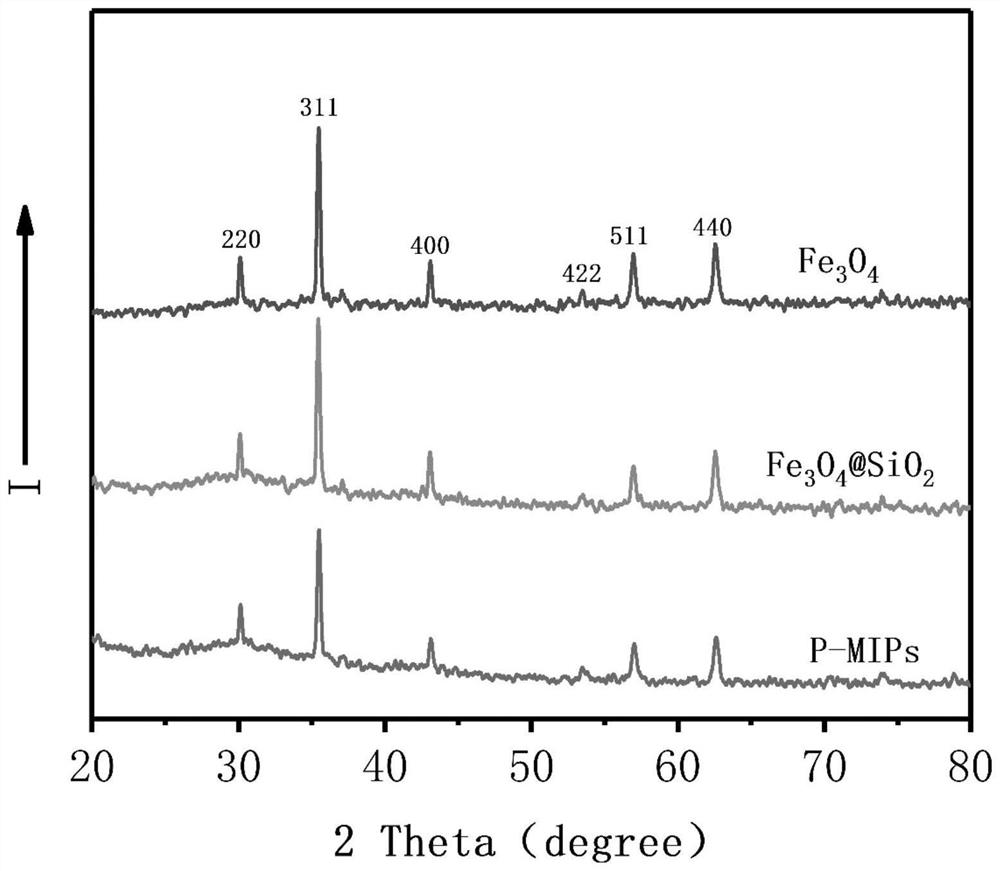

Image

Examples

Embodiment 1

[0048] Step (1) synthesis of p-hydroxyazobenzenesulfonic acid (MAPASA): add 12g p-aminobenzenesulfonic acid successively in there-necked flask, 10g K 2 CO 3 and water, stirring to dissolve completely. Placed in a low-temperature constant temperature water tank at -6°C, mechanically stirred, and 8g NaNO 2 Dissolve in 10mL of water, slowly drop into the three-necked flask, then slowly add 10mL of hydrochloric acid dropwise into the there-necked flask, and keep the temperature at 0°C for 0.5h. (Record the reaction solution as A) Add 7g phenol, 17g K 2 CO 3 and 10 mL of distilled water (record the reaction solution as B). Put it in a low-temperature constant temperature water tank, turn on the mechanical stirring, slowly add the reaction liquid A to the liquid B dropwise, maintain a suitable temperature, and continue to stir for 2 hours. After the reaction is completed, the temperature is naturally raised to room temperature, the mixed solution is adjusted to pH=2 with HCl, f...

Embodiment 2

[0056] Step (1), the synthesis of p-hydroxyazobenzenesulfonic acid (MAPASA): in there-necked flask, add 14g p-aminobenzenesulfonic acid successively, 11g K 2 CO 3 and water, stirred to dissolve completely; placed in a low-temperature constant temperature water tank at -5°C, mechanically stirred, and 8.3g NaNO 2Dissolve in 15mL of water, slowly drop into the three-necked bottle, then slowly add 15mL of hydrochloric acid dropwise into the three-necked bottle, and keep the temperature at 3°C for 1h. (Record the reaction solution as A) Add 8g phenol, 18g K 2 CO 3 Mixed solution with 15mL distilled water (record the reaction solution as B); place it in a low-temperature constant temperature water tank, turn on the mechanical stirring, slowly add the reaction solution A to the solution B, maintain a suitable temperature, and continue to stir for 2.5h. After the reaction is completed, the temperature is naturally raised to room temperature, the mixed solution is adjusted to pH =...

Embodiment 3

[0064] Step (1), the synthesis of p-hydroxyazobenzenesulfonic acid (MAPASA): in there-necked flask, add 15g p-aminobenzenesulfonic acid successively, 12g K 2 CO 3 and water, stirring to dissolve completely. Placed in a low-temperature constant temperature water tank at -4°C, mechanically stirred, and 9g NaNO 2 Dissolve in 20mL of water, slowly drop into the three-necked bottle, then slowly add 20mL of hydrochloric acid dropwise into the there-necked bottle, and keep the temperature at 10°C for 2h. (Record the reaction solution as A) Add 9g phenol, 19g K 2 CO 3 and 20mL of distilled water (denote the reaction solution as B); place it in a low-temperature constant temperature water tank, turn on the mechanical stirring, slowly add the reaction solution A to the B solution, maintain a suitable temperature, and continue to stir for 3h; after the reaction is completed, Let the temperature rise to room temperature naturally, adjust the pH of the mixture to 4 with HCl, filter, wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com