A preparation method and application of polymethyl methacrylate nanosphere-molecularly imprinted fluorescent material

A technology of polymethyl methacrylate and methyl methacrylate, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of limited application and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

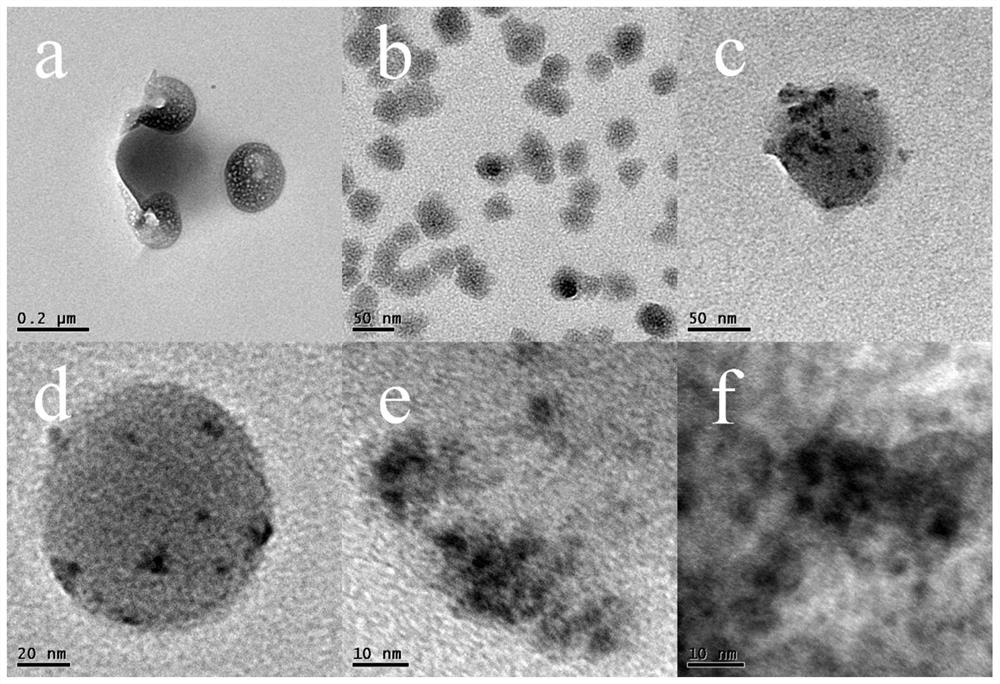

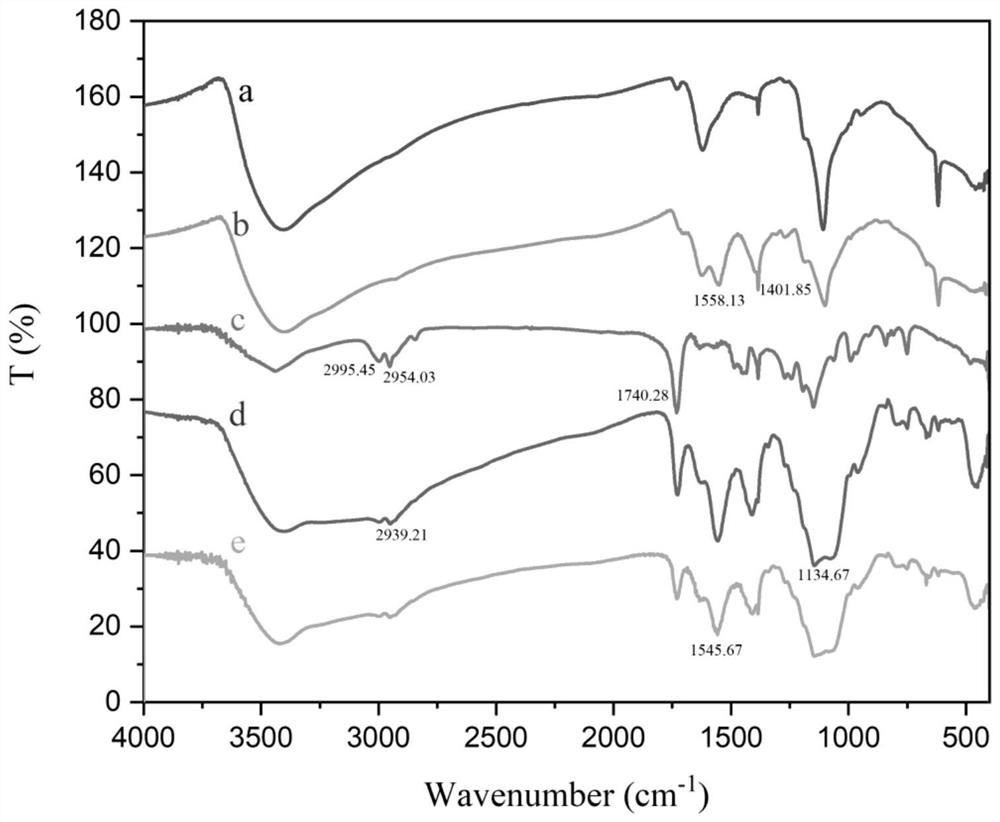

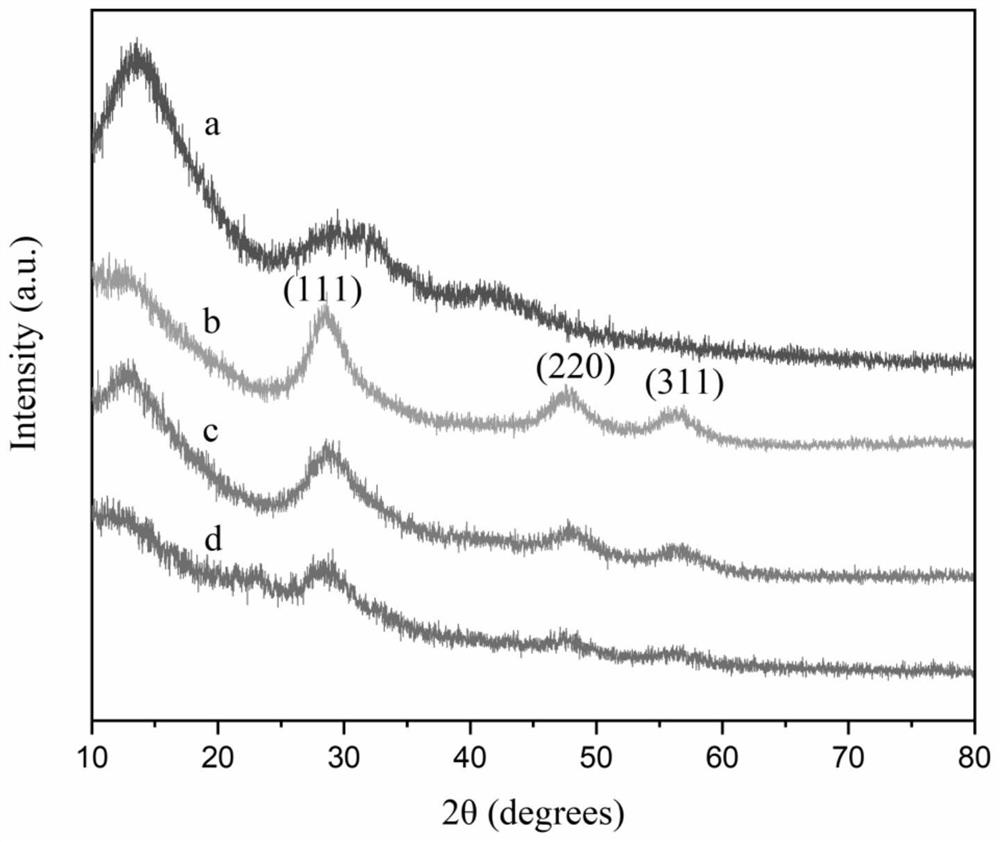

Image

Examples

Embodiment 1

[0038] Step 1. Synthesis of PMMA nanoparticles: prepared by soap-free polymerization method, 5 mL of MMA was added to a 250 mL three-necked flask containing 70 mL of ethanol, stirred for 10 min under nitrogen atmosphere; then, 0.01 g of SDBS was added and reacted for 20 min; Subsequently, 20 mL of 0.1 g of K was added dropwise 2 S 2 o 8 , the temperature was raised to 85°C, stirred and reacted for 3 hours, and a mixed solution was obtained after the reaction; then anhydrous calcium chloride solution equal to the volume of the mixed solution was added to precipitate with 1M saturated anhydrous calcium chloride, and after centrifugation at 8000rmp, a solid product was obtained, which was washed with ethanol and water After washing, dry in a vacuum oven at 55°C for 12 hours to obtain PMMA nanoparticles, which are referred to as PMMANs;

[0039] Step 2, the synthesis of the manganese-doped zinc sulfide quantum dots modified by mercaptopropionic acid:

[0040] 11mmol of ZnSO 4 ...

Embodiment 2

[0045] Synthesis of step 1, PMMA nanoparticles:

[0046] Prepared by soap-free polymerization method, 10mL of MMA was added to a 250mL three-necked flask containing 80mL of ethanol, stirred for 20min under nitrogen atmosphere; then, 0.049g of SDBS was added and reacted for 30min; then, 20mL of 0.26g of MMA was added dropwise K 2 S 2 o 8 , the temperature was raised to 85°C, and the reaction was stirred for 4 hours. After the reaction, an equal volume of 2M saturated anhydrous calcium chloride solution was added for precipitation. After centrifugation at 8000rmp, a solid product was obtained. After washing with ethanol and water, put Dry in a vacuum oven at 55°C for 12 hours to obtain PMMA nanoparticles, which are referred to as PMMANs;

[0047] Step 2, the synthesis of the manganese-doped zinc sulfide quantum dots modified by mercaptopropionic acid:

[0048] 12.5mmol of ZnSO 4 ·7H 2 O and 1 mmol MnCl 2 4H2O was added to 40mL of twice distilled water, stirred for 10min u...

Embodiment 3

[0053] Synthesis of step 1, PMMA nanoparticles

[0054] Prepared by soap-free polymerization method, 15mL of MMA was added to a 250mL three-neck flask containing 90mL of ethanol, stirred for 30min under nitrogen atmosphere; then, 0.08g of SDBS was added and reacted for 30min; then, 15mL of 0.3g of MMA was added dropwise K 2 S 2 o 8 , the temperature was raised to 85°C, and the reaction was stirred for 6 hours; after the reaction, a mixed solution was obtained, and a 3M saturated anhydrous calcium chloride solution equal to the volume of the mixed solution was added for precipitation. After washing with water, dry in a vacuum oven at 55°C for 12 hours to obtain PMMA nanoparticles, which are referred to as PMMANs;

[0055] Step 2. Synthesis of manganese-doped zinc sulfide quantum dots modified by mercaptopropionic acid

[0056] 13mmol of ZnSO 4 ·7H 2 O and 1.5 mmol of MnCl 2 4H 2 O was added to 50 mL of double-distilled water, and stirred under nitrogen atmosphere for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com