A preparation method and application of magnetic iron ferric oxide nanoparticles-ph responsive imprinted material

A technology of ferric tetroxide and nanoparticles, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc. Effects of pH-responsive performance, increasing specific adsorption sites, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

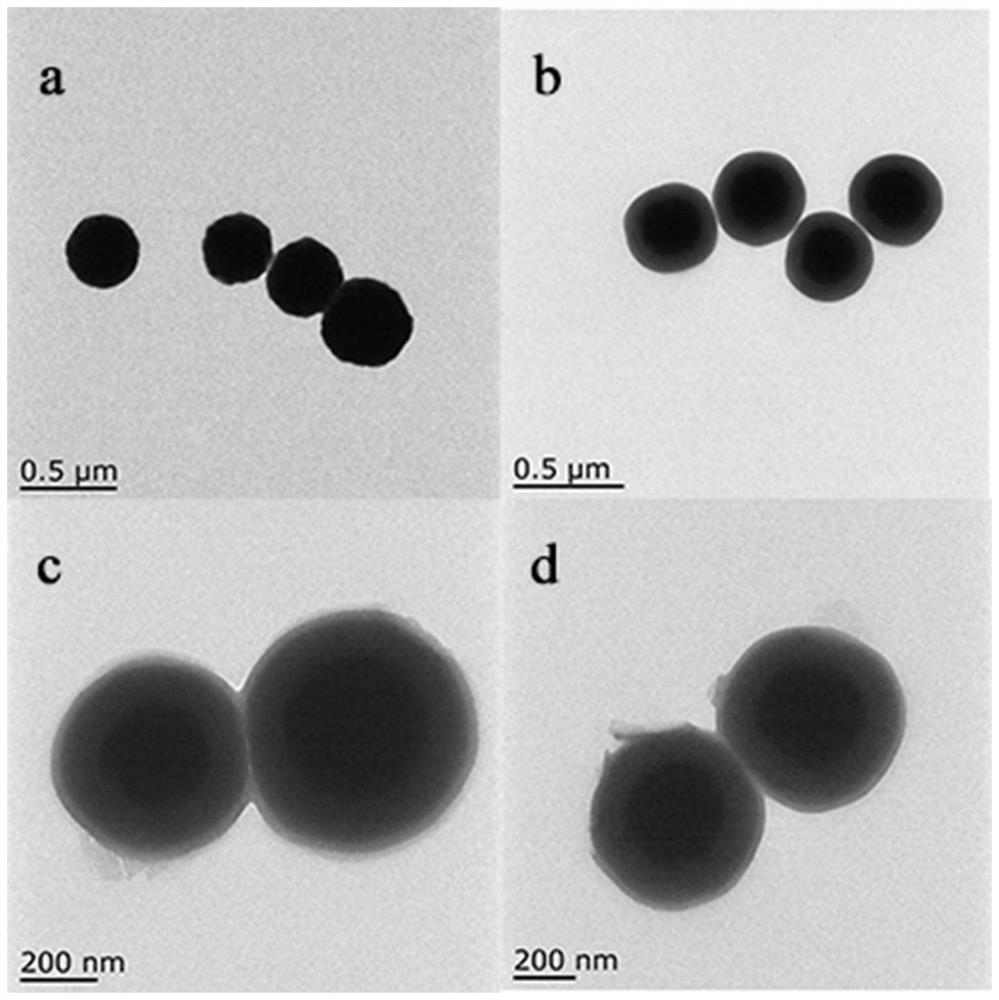

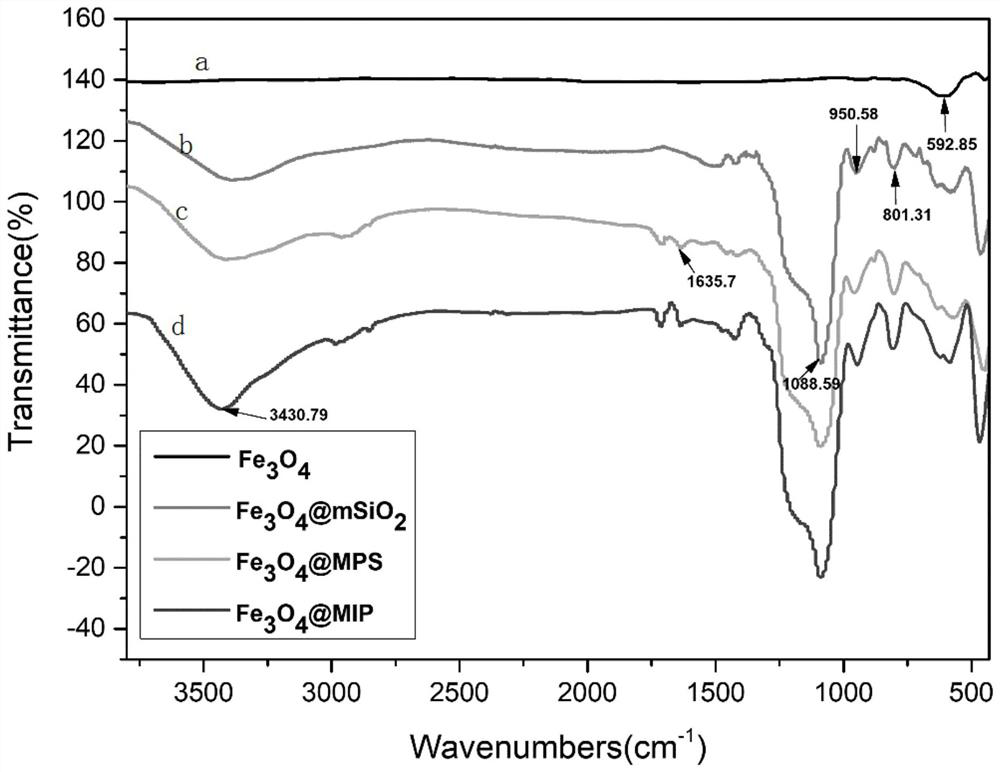

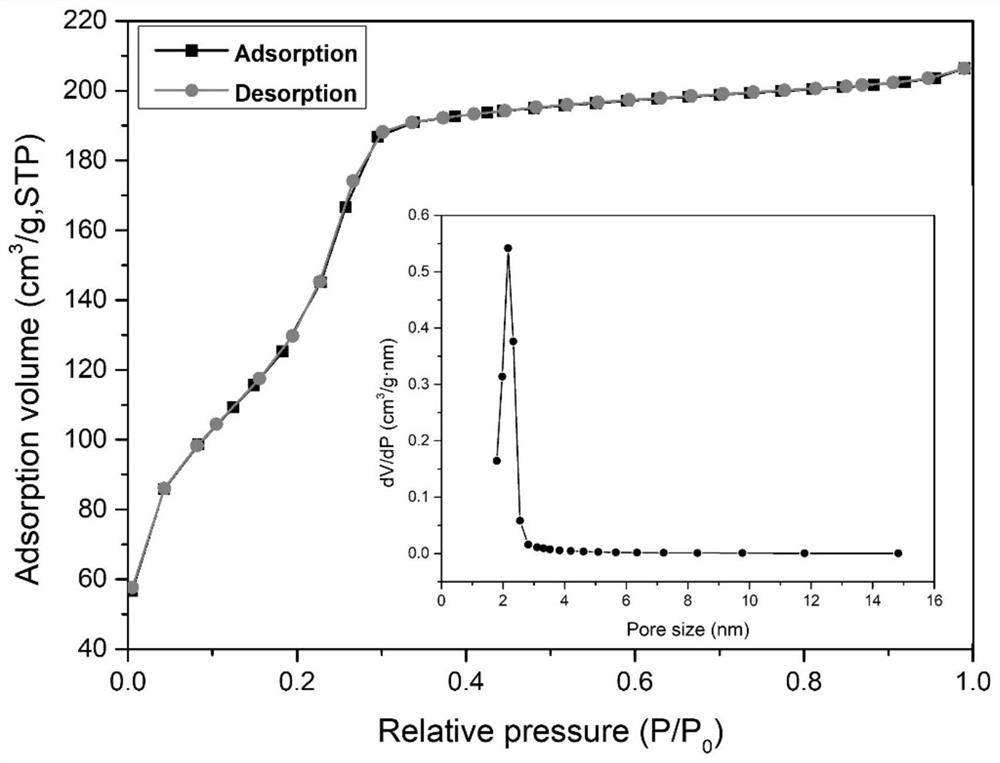

[0036] Step 1, Fe 3 o 4 Preparation of nanoparticles: 1.2g FeCl 3 ·6H 2 O was added to 50mL of ethylene glycol, and stirred for 20min until the solution was clear, followed by adding 3.2g of sodium acetate (NaAc), 0.5g of trisodium citrate (NaAc 3 Cit) and 0.7g polyethylene glycol, after being magnetically stirred for 40min, the mixed solution was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, reacted at a high temperature of 180°C for 8h, and then naturally cooled to room temperature; finally, a black precipitate The material was washed with distilled water and ethanol, and dried in vacuum at 60 °C to obtain Fe 3 o 4 Nanoparticles;

[0037] Step 2, the Fe obtained in step 1 3 o 4 Add 0.25 g of nanoparticles to a mixed solution containing 0.5 g of cetyltrimethylammonium bromide (CTAB), 2.5 mL of ammonia water, 60 mL of ethanol and 15 mL of deionized water. After ultrasonication for 10 min, 2.5 mL of orthosilicic acid Tetraethyl ester (TE...

Embodiment 2

[0042] Step 1, Fe 3 o 4 Preparation of nanoparticles: 1.35g FeCl 3 ·6H 2 O was added to 60mL of ethylene glycol, and stirred for 30min until the solution was clear, followed by adding 3.6g of sodium acetate (NaAc), 0.72g of trisodium citrate (NaAc 3 Cit) and 1g polyethylene glycol; after magnetic stirring for 50min, the mixed solution was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, and after a high temperature reaction at 200°C for 10h, it was naturally cooled to room temperature; finally, a black precipitate Wash with distilled water and ethanol respectively, and dry in vacuum at 65 °C to obtain Fe 3 o 4 Nanoparticles;

[0043] Step 2, the Fe obtained in step 1 3 o 4 Add 0.3 g of nanoparticles to a mixed solution containing 0.6 g of cetyltrimethylammonium bromide (CTAB), 3 mL of ammonia water, 80 mL of ethanol and 20 mL of deionized water. After ultrasonication for 15 min, 3 mL of tetraethylorthosilicate Ester (TEOS) was slowly added...

Embodiment 3

[0048] Step 1, Fe 3 o 4 Preparation of nanoparticles: 1.5g FeCl 3 ·6H 2 O was added to 80mL of ethylene glycol, and stirred for 40min until the solution was clear, followed by adding 3.9g of sodium acetate (NaAc), 0.89g of trisodium citrate (NaAc 3 Cit) and 1.2g polyethylene glycol; after magnetic stirring for 60min, the mixed solution was transferred to a stainless steel autoclave lined with polytetrafluoroethylene. After reacting at a high temperature of 220°C for 12 hours, it was naturally cooled to room temperature. Finally, the black precipitate was washed with distilled water and ethanol, and dried in vacuum at 75°C to obtain Fe 3 o 4 Nanoparticles;

[0049] Step 2, the Fe obtained in step 1 3 o 4 Add 0.35 g of nanoparticles to a mixed solution containing 0.7 g of cetyltrimethylammonium bromide (CTAB), 5 mL of ammonia water, 100 mL of ethanol and 25 mL of deionized water. After ultrasonication for 30 min, 3.5 mL of orthosilicate Ethyl ester (TEOS) was slowly add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com