Super capacitor positive electrode material based on conductive polymer, and preparation method thereof

A technology of supercapacitors and conductive polymers, applied in the field of electrochemical materials, can solve the problems of reduced specific capacitance and poor cycle performance, and achieve the effects of increasing specific capacitance, avoiding damage, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of supercapacitor cathode material based on conductive polymer, concrete steps are as follows:

[0043] (1) Dissolve 137.9g (2mol) of lithium nitrate and 211.6g (1mol) of strontium nitrate in 1103.2g of water, then add 469.5g (8mol) of nickel foam, ultrasonically oscillate, and hydrothermally react to obtain the precursor;

[0044] (2) Then the precursor is heat-treated in an air atmosphere to obtain a metal oxide composite material;

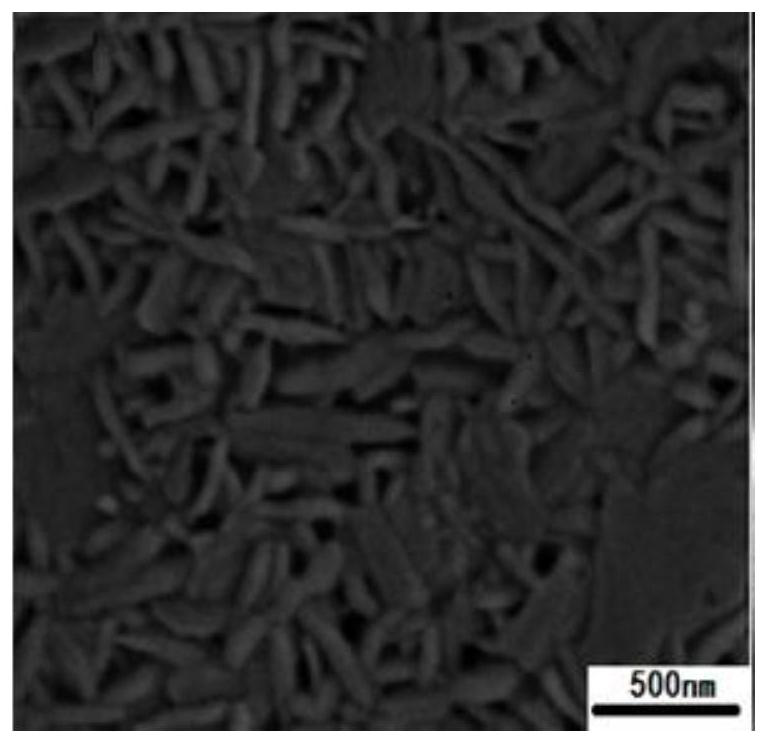

[0045] (3) Finally, the metal oxide composite material and α-naphthylamine monomer and 3-(4-fluorophenyl) thiophene monomer are used as raw materials for polymerization reaction to obtain a supercapacitor positive electrode material based on conductive polymer ( SEM image see figure 1 );

[0046]Among them, the metal oxide composite material is modified before participating in the polymerization reaction. The specific method is: crush 1g of the metal oxide composite material to a particle size below 10μm, ...

Embodiment 2

[0064] A kind of preparation method of supercapacitor cathode material based on conductive polymer, concrete steps are as follows:

[0065] (1) Dissolve 137.9g (2mol) of lithium nitrate and 211.6g (1mol) of strontium nitrate in 1379g of water, then add 469.5g (8mol) of nickel foam, ultrasonically oscillate, and hydrothermally react to obtain the precursor;

[0066] (2) Then the precursor is heat-treated in an air atmosphere to obtain a metal oxide composite material;

[0067] (3) Finally, the metal oxide composite material and α-naphthylamine monomer and 3-(4-fluorophenyl)thiophene monomer are used as raw materials for polymerization reaction to obtain a supercapacitor positive electrode material based on conductive polymer;

[0068] Among them, the metal oxide composite material is modified before participating in the polymerization reaction. The specific method is: crush 1g of the metal oxide composite material to a particle size below 10μm, pour it into 5g of water contai...

Embodiment 3

[0086] A kind of preparation method of supercapacitor cathode material based on conductive polymer, concrete steps are as follows:

[0087] (1) Dissolve 137.9g (2mol) of lithium nitrate and 211.6g (1mol) of strontium nitrate in 1200g of water, then add 469.5g (8mol) of nickel foam, ultrasonically oscillate, and react hydrothermally to obtain the precursor;

[0088] (2) Then the precursor is heat-treated in an air atmosphere to obtain a metal oxide composite material;

[0089] (3) Finally, the metal oxide composite material and α-naphthylamine monomer and 3-(4-fluorophenyl)thiophene monomer are used as raw materials for polymerization reaction to obtain a supercapacitor positive electrode material based on conductive polymer;

[0090] Among them, the metal oxide composite material is modified before participating in the polymerization reaction. The specific method is: crush 1 g of the metal oxide composite material to a particle size below 10 μm, pour it into 6 g of water con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com