Method for preparing high-solubility full-ingredient lonicera japonica extract

A technology of honeysuckle extract and high solubility, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, functions of food ingredients, etc. , limit the scope of application, etc., to avoid the enrichment of aroma resin, good water solubility, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

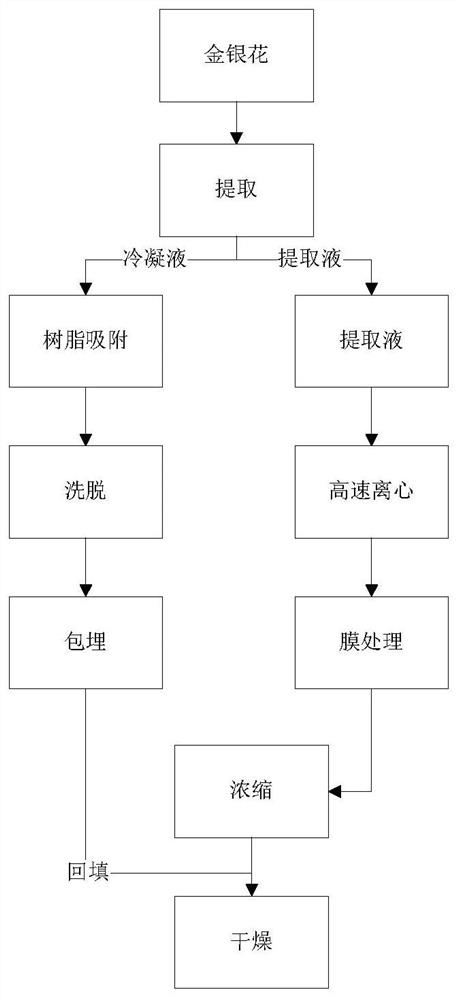

[0030] refer to figure 1 The flow process of a kind of highly soluble full-component honeysuckle extract preparation method comprises the following steps:

[0031] (1) Extraction: take 10Kg of pulverized honeysuckle raw materials, pass through a 30-mesh sieve, add 20 times the volume of pure water for extraction, extract three times, each time for 3 hours, the extraction temperature is 95 ° C, and combine the extracts.

[0032] (2) Disc centrifugation: use a disc centrifuge to centrifuge the above extract, and collect the centrifugate.

[0033] (3) Membrane filtration: the above centrifugal liquid is filtered by a ceramic membrane with a pore size of 1.4 μm.

[0034] (4) Concentration: The above-mentioned filtrate is concentrated under reduced pressure to a solid content of 61.3%, and the concentration temperature is required to be 40-75°C.

[0035] (5) Resin adsorption: The condensate in the extraction process of step (1) is returned to the extraction tank through XDA-8G re...

Embodiment 2

[0041] A preparation method of a highly soluble full-component honeysuckle extract, comprising the steps of:

[0042] (1) Extraction: Get 10Kg of pulverized honeysuckle raw materials, pass through a 30 mesh sieve, add 15 times the volume of 30% ethanol to heat and reflux for extraction, extract three times, each time for 2 hours, and combine the extracts.

[0043] (2) Disc centrifugation: use a disc centrifuge to centrifuge the above extract, and collect the centrifugate.

[0044] (3) Membrane filtration: the above centrifugal liquid is filtered by a ceramic membrane with a pore size of 0.05 μm.

[0045] (4) Concentration: the above-mentioned filtrate is concentrated under reduced pressure to a solid content of 68.5%, and the concentration temperature is required to be 40-75°C.

[0046] (5) Resin adsorption: the condensate in the extraction process of step (1) is returned to the extraction tank through XDA-8G resin to enrich and recover the aroma components in the condensate,...

Embodiment 3

[0052] A preparation method of a highly soluble full-component honeysuckle extract, comprising the steps of:

[0053] (1) Extraction: Get 10Kg of pulverized honeysuckle raw materials, pass through a 30 mesh sieve, add 8 times the volume of 50% ethanol to heat and reflux for extraction, extract three times, each time for 1 to 3 hours, and combine the extracts.

[0054](2) Disc centrifugation: use a disc centrifuge to centrifuge the above extract, and collect the centrifugate.

[0055] (3) Membrane filtration: the above centrifuge is filtered by a ceramic membrane with a pore size of 0.02.

[0056] (4) Concentration: The above-mentioned filtrate is concentrated under reduced pressure to a solid content of 70.3% or more, and the concentration temperature is required to be 40-75°C.

[0057] (5) Resin adsorption: The condensate in the extraction process of step (1) is returned to the extraction tank through LX-3020 resin to enrich and recover the aroma components in the condensate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com