Preparation method of light fireproof composite material

A composite material, lightweight technology, used in chemical instruments and methods, flat products, synthetic resin layered products, etc., can solve the problems of large smoke generation, limited application, not environmental protection, etc., achieve high structural strength, excellent fire resistance The effect of flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] This scheme also provides a preparation method of lightweight fireproof composite material, the operation steps include:

[0018] (1) Material equipment: prepare the mold to be used, and prepare the resin glue;

[0019] (2) Molding preparation: brush the phenolic resin mixture containing the curing agent on the mold, and then lay a layer of fiber fabric cut according to the requirements on it, and squeeze the fabric with a brush, press or scraper to make it evenly impregnated. After gluing and removing air bubbles, paint the epoxy resin mixture, spread the second layer of fiber fabric and flame retardant, make it evenly dipped in glue and remove air bubbles, then paint the phenolic resin mixture containing the curing agent, and then coat it Lay a layer of fiber fabric that has been cut according to the requirements, so that it can be evenly dipped in glue and remove air bubbles;

[0020] (3) Curing: under a certain pressure, heat and cure the above-mentioned lay-up str...

Embodiment 1

[0026] Example 1: High-strength fireproof composite material board (2mm thickness), its layer structure: 1 layer of 400g / ㎡weight phenolic prepreg (formula composition is the same as Comparative Example 3) + 7 layers of epoxy prepreg (formula composition : 60wt% glass fiber, 5wt% flame retardant (a combination of aluminum hydroxide and ammonium polyphosphate), 35wt% epoxy resin.)+1 layer of 400g / ㎡ weight phenolic prepreg (formulation is the same as Comparative Example 3), After lamination, hot pressing and compounding are prepared to obtain a composite material sheet.

Embodiment 2

[0027] Example two: high-strength fireproof composite material board (2mm thickness), its layer structure: 1 layer of phenolic prepreg with a weight of 400g / ㎡ (formula composition is the same as Comparative Example 3) + 7 layers of epoxy prepreg (formula composition Same as Comparative Example 1) + 1 layer of phenolic prepreg with a weight of 400g / ㎡ (the formula composition is the same as Comparative Example 3), after laying up layers, heat-compress and compound to prepare a composite material board.

[0028]

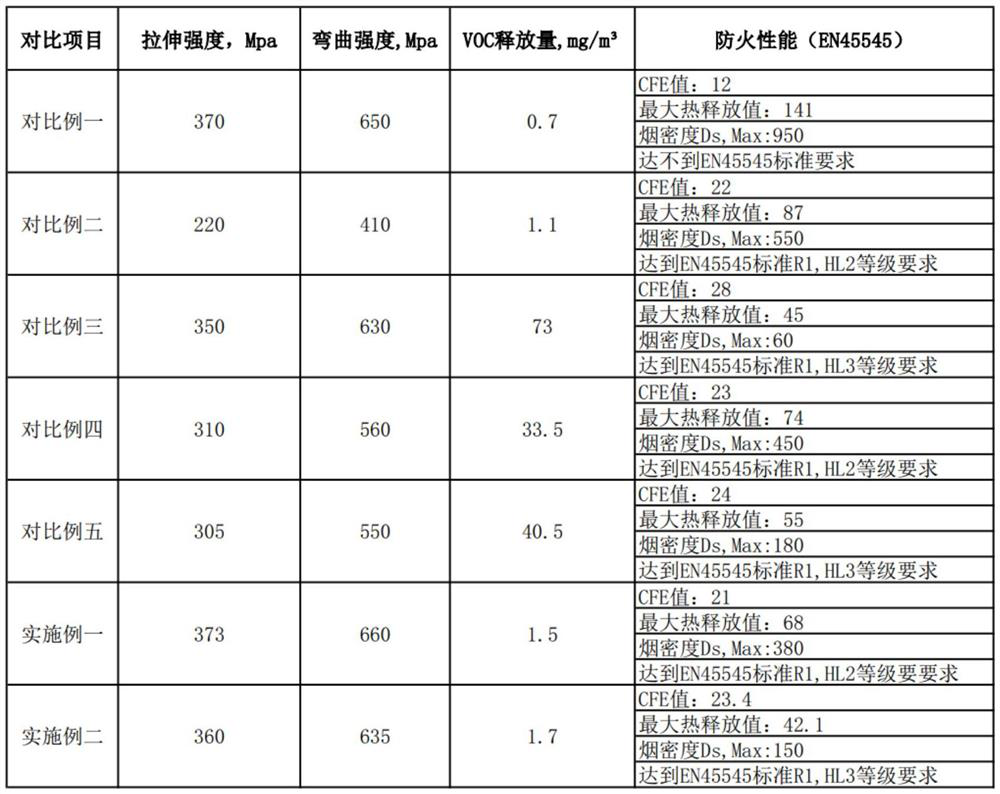

[0029] From the above Comparative Examples 1-5 and Examples 1 and 2, it can be seen that compared with Comparative Example 1, the fire performance of the composite material has been significantly improved after the surface layer is designed as a phenolic resin system, while maintaining the original There is the excellent mechanical strength of epoxy composite material; Example 2 is compared with comparative example 4,5, shows that only when the phenolic / epoxy composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com