Production process for increasing yield of thiophosphoryl chloride

A technology for the production process of phosphorous trichloride, which is applied in the field of production process for improving the yield of phosphorous trichloride, can solve the problems of residual residue, increase of production cost, and difficult cleaning of residue, so as to avoid pollution, avoid waste, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

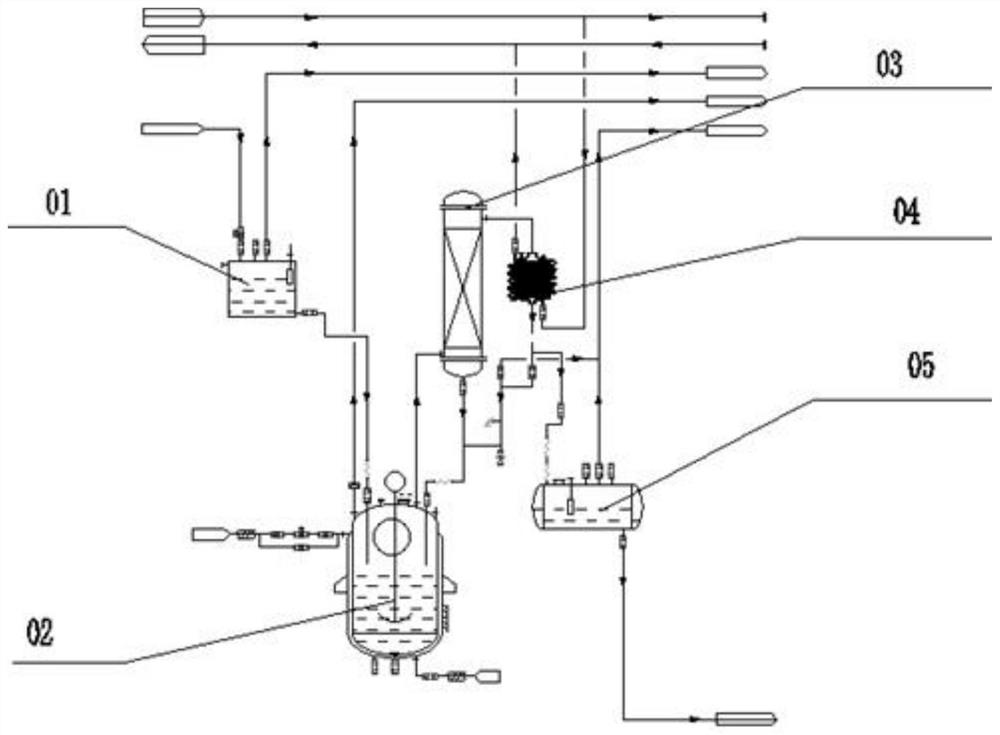

[0032] A production technique for improving the yield of phosphorus trichloride, specifically comprising the following steps:

[0033]Step S1, prepare the following raw materials in parts by weight, 10 parts of sulfur, 5 parts of phosphorus trichloride, and 50 parts of phosphorus trichloride, set aside;

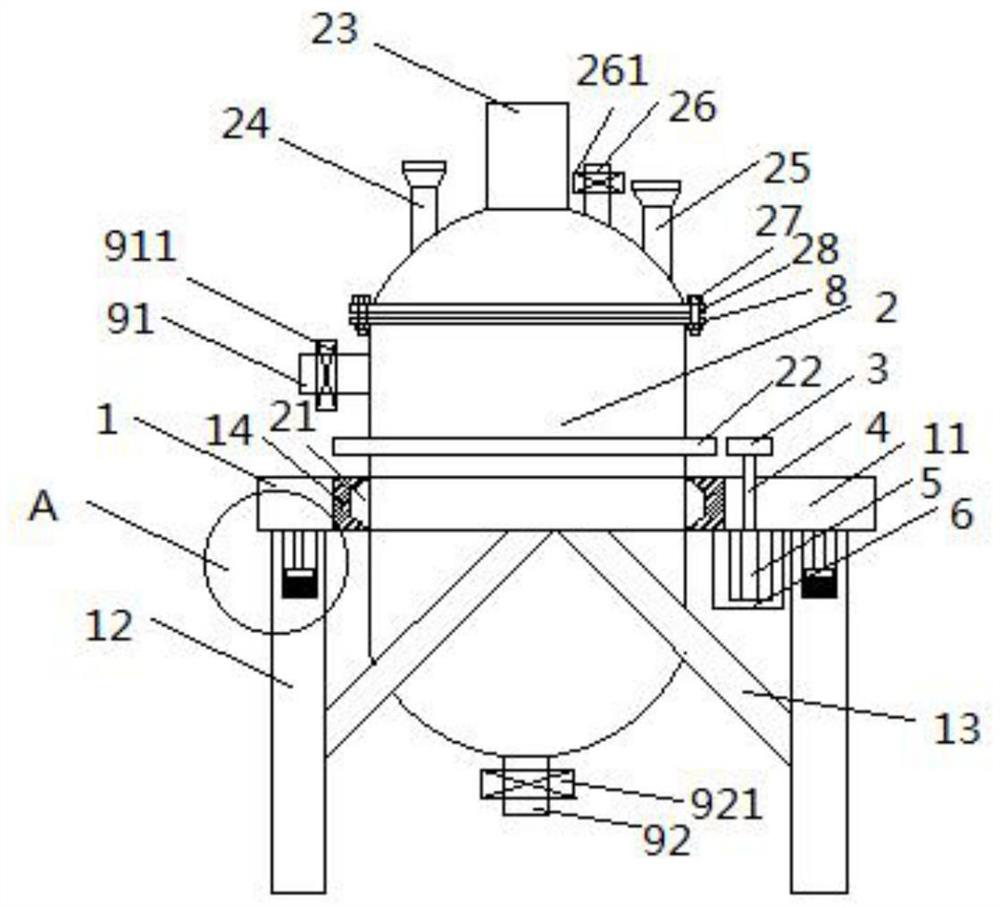

[0034] Step S2: Add phosphorus trichloride into the raw material metering tank 01, put sulfur into the reactor 02 through the solid feed pipe 24, raise the temperature in the reactor 02 to 120°C, make the sulfur molten, and then turn on the second Two motors 231, rotating speed 50r / min stirring 5min, connect the discharge end of raw material metering tank 01 with liquid feed pipe 25, then make phosphorus trichloride enter reaction kettle 02 through dispersing pipe 251 and dropper 252, control reaction tank 2 When the internal temperature is 124°C, turn on the second motor 231 again, start the first motor 5 at the same time, and stir at a speed of 150r / min for 30min, so that s...

Embodiment 2

[0037] A production technique for improving the yield of phosphorus trichloride, specifically comprising the following steps:

[0038] Step S1, prepare the following raw materials in parts by weight, 13 parts of sulfur, 8 parts of phosphorus trichloride, and 65 parts of phosphorus trichloride, for later use;

[0039] Step S2: Add phosphorus trichloride into the raw material metering tank 01, put sulfur into the reactor 02 through the solid feed pipe 24, raise the temperature in the reactor 02 to 125°C, make the sulfur molten, and then turn on the second Two motors 231, rotating speed 80r / min stirring 8min, connect the discharge end of raw material metering tank 01 with liquid feed pipe 25, then make phosphorus trichloride enter reaction kettle 02 through dispersion pipe 251 and dropper 252, control reaction tank 2 The inner temperature is 125°C, turn on the second motor 231 again, and start the first motor 5 at the same time, and stir at a rotating speed of 200r / min for 35min,...

Embodiment 3

[0042] A production technique for improving the yield of phosphorus trichloride, specifically comprising the following steps:

[0043] Step S1, prepare the following raw materials in parts by weight, 16 parts of sulfur, 10 parts of phosphorus trichloride, and 80 parts of phosphorus trichloride, set aside;

[0044] Step S2: Add phosphorus trichloride into the raw material metering tank 01, put sulfur into the reactor 02 through the solid feed pipe 24, raise the temperature in the reactor 02 to 130°C, make the sulfur molten, and then turn on the second Two motors 231, rotating speed 100r / min and stirring for 10min, connect the discharge end of the raw material metering tank 01 with the liquid feed pipe 25, then make phosphorus trichloride enter the reactor 02 through the dispersion pipe 251 and the dropper 252, and control the reactor tank 2 When the internal temperature is 126°C, turn on the second motor 231 again, start the first motor 5 at the same time, and stir at a rotatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com