Nitrile rubber sealing ring

A technology of nitrile rubber and sealing rings, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of short service life and not wide range of use, so as to improve temperature resistance, increase the range of use, and reduce fire accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

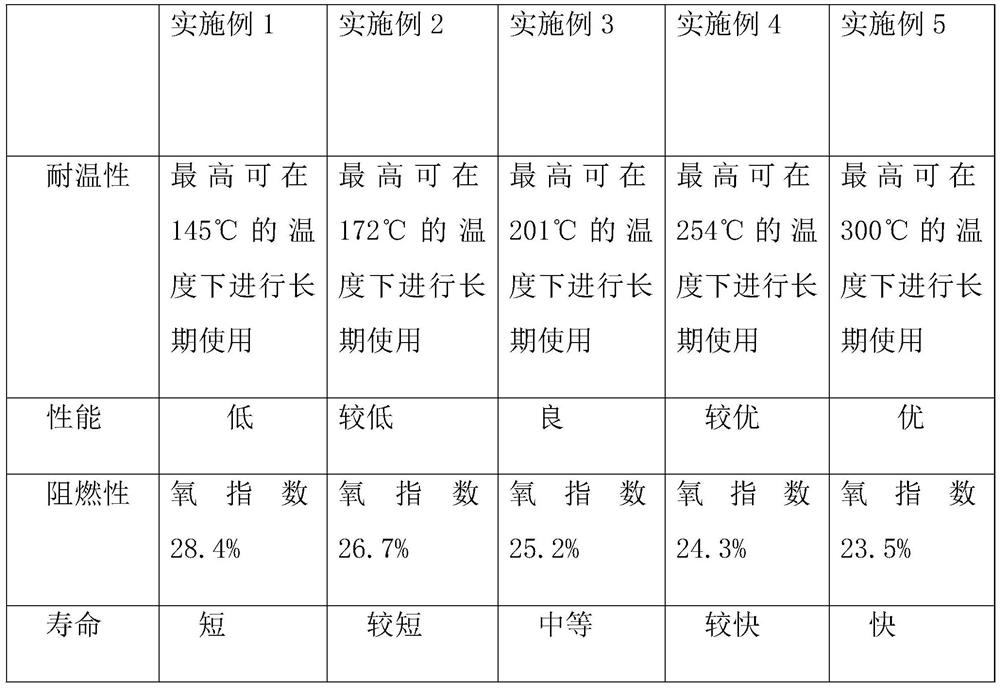

Examples

Embodiment 1

[0027] A kind of nitrile rubber sealing ring provided by the invention comprises main material and auxiliary material;

[0028] Further, the main material (by weight) includes: nitrile rubber, and the auxiliary materials (by weight) include: silicone rubber, perfluoroether rubber, polyether ether ketone, chlorosulfonated polyethylene, vulcanizing agent, Softener, adhesive, accelerator DPTT, reinforcing agent, flame retardant, color masterbatch.

[0029] Further, each component (by weight) in the main material and the auxiliary material is: nitrile rubber: 80g, silicone rubber: 10g, perfluoroether rubber: 10g, polyether ether ketone: 4g, chlorosulfonated Polyethylene: 8g, vulcanizing agent: 8g, softener: 2g, adhesive: 3g, accelerator DPTT: 2g, reinforcing agent: 2g, flame retardant: 5g, color masterbatch: 2g.

[0030] Further, the softener is composed of paraffin and asphalt.

[0031] Further, the material of the vulcanizing agent is N′-m-phenylene bismaleimide.

[0032] Fur...

Embodiment 2

[0044] A kind of nitrile rubber sealing ring provided by the invention comprises main material and auxiliary material;

[0045] Further, the main material (by weight) includes: nitrile rubber, and the auxiliary materials (by weight) include: silicone rubber, perfluoroether rubber, polyether ether ketone, chlorosulfonated polyethylene, vulcanizing agent, Softener, adhesive, accelerator DPTT, reinforcing agent, flame retardant, color masterbatch.

[0046] Further, the ingredients (by weight) in the main material and the auxiliary materials are: nitrile rubber: 85g, silicone rubber: 12.5g, perfluoroether rubber: 12.5g, polyether ether ketone: 5g, chlorine Sulfonated polyethylene: 9.75g, vulcanizing agent: 9.75g, softener: 2.5g, binder: 3.5g, accelerator DPTT: 3g, reinforcing agent: 3g, flame retardant: 6.25g, masterbatch: 2.5 g.

[0047] Further, the softener is composed of paraffin and asphalt.

[0048] Further, the material of the vulcanizing agent is N′-m-phenylene bismalei...

Embodiment 3

[0061] A kind of nitrile rubber sealing ring provided by the invention comprises main material and auxiliary material;

[0062] Further, the main material (by weight) includes: nitrile rubber, and the auxiliary materials (by weight) include: silicone rubber, perfluoroether rubber, polyether ether ketone, chlorosulfonated polyethylene, vulcanizing agent, Softener, adhesive, accelerator DPTT, reinforcing agent, flame retardant, color masterbatch.

[0063] Further, the ingredients (by weight) in the main material and the auxiliary materials are: nitrile rubber: 90g, silicone rubber: 15g, perfluoroether rubber: 15g, polyether ether ketone: 6g, chlorosulfonated Polyethylene: 11.5g, vulcanizing agent: 11.5g, softener: 3g, adhesive: 4g, accelerator DPTT: 4g, reinforcing agent: 4g, flame retardant: 7.5g, color masterbatch: 3g.

[0064] Further, the softener is composed of paraffin and asphalt.

[0065] Further, the material of the vulcanizing agent is N′-m-phenylene bismaleimide.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com