Thermally induced memory foam insole material and preparation method thereof

A foamed sheet and memory technology, applied in the field of shoe manufacturing, can solve the problems of inability to use foamed materials, cumbersome process steps, harsh foaming conditions, etc., and achieve excellent resilience and cushioning performance, simple process steps, The effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The present invention also provides a method for preparing the thermal memory foam insole material described in the above technical solution, comprising the following steps:

[0067] a) Densify trans-1,4-polyisoprene rubber, EVA, POE, SEBS, talc, peroxide cross-linking agent, foaming agent, zinc oxide, stearic acid and zinc stearate Refining to obtain mixture A;

[0068] b) After kneading the mixed material A obtained in step a), hot-pressing and foaming are carried out to obtain a foamed sheet;

[0069] c) The foamed sheet obtained in step b) is sequentially sliced, cloth-covered and cut to obtain a heat-induced memory foamed insole material.

[0070] The present invention first carries out trans-1,4-polyisoprene rubber, EVA, POE, SEBS, talcum powder, peroxide crosslinking agent, foaming agent, zinc oxide, stearic acid and zinc stearate Banbury mixing, obtain compound A. In the present invention, the trans-1,4-polyisoprene rubber, EVA, POE, SEBS, talcum powder, pero...

Embodiment 1~8 and comparative example 1~8

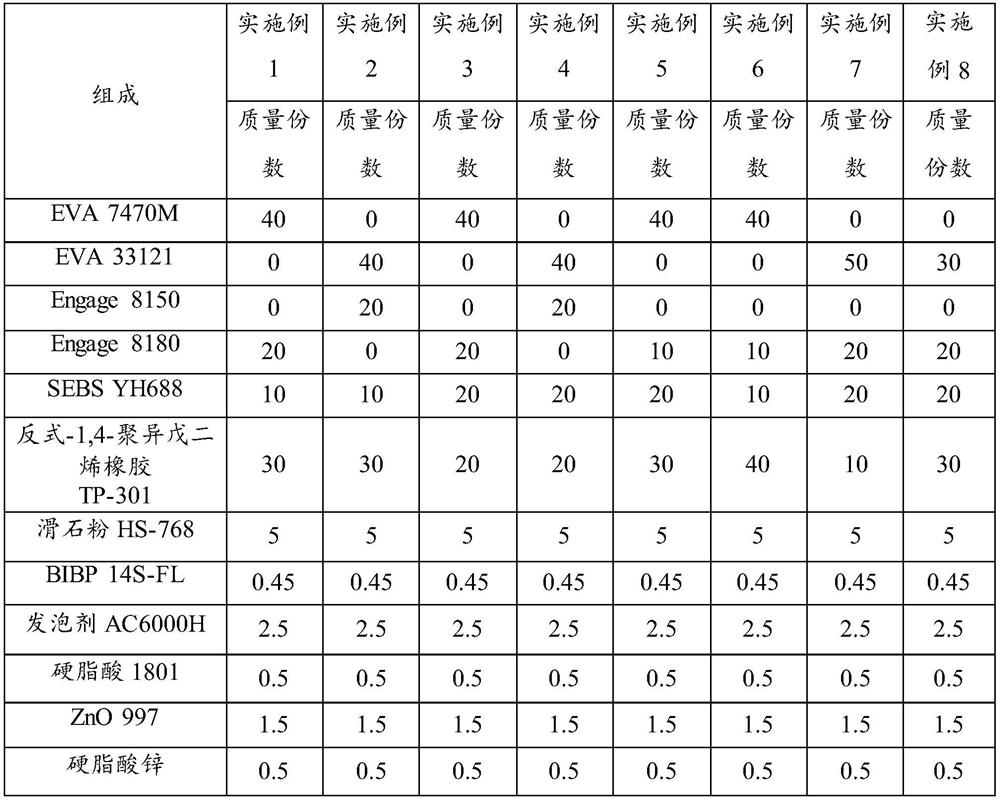

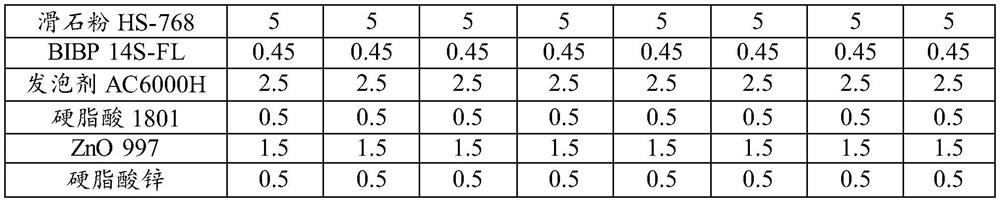

[0095] (1) Formula composition:

[0096] See Tables 1-2, wherein, Table 1 is the formula composition of the thermal memory foam insole material provided in Examples 1-8, and Table 2 is the formula composition of the foam insole material provided in Comparative Examples 1-8.

[0097] The formula composition of the heat-induced memory foam insole material that table 1 embodiment 1~8 provides

[0098]

[0099] The formula composition of the foamed insole material that table 2 comparative example 1~8 provides

[0100]

[0101]

[0102] in:

[0103] EVA 7350M: VA molar content is 18%, hardness is 88A, melting point is 84°C, softening temperature is 49°C, crystallinity is 36.5%, Formosa Plastics Corporation.

[0104] EVA 7470M: VA molar content is 26%, hardness is 82A, melting point is 76°C, softening temperature is 43°C, crystallinity is 24.8%, Formosa Plastics Corporation.

[0105] EVA 33121: VA molar content 33%, hardness 65A, melting point 67°C, softening temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com