Production method of recombined bamboo-ardealite composite partition board

A production method and technology of phosphogypsum, applied in sound insulation, building components, applications, etc., can solve problems such as waste of resources, and achieve the effects of strong fire resistance, low cost, and high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Soaking moso bamboo in a mixed solution of water-soluble phenolic resin glue and a flame retardant after decomposing and carbonizing, then pulling it out and drying it to obtain bamboo bundles;

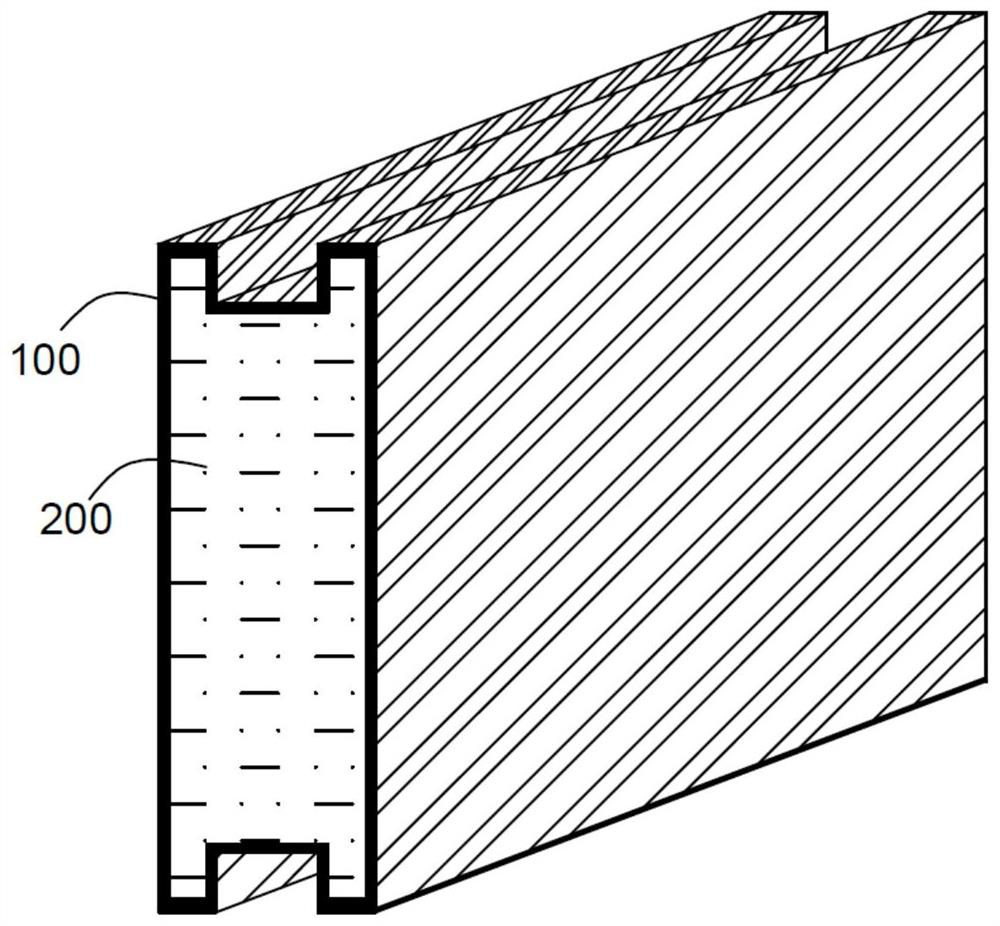

[0025] 2) Get the bamboo bundles and place them in the mould, and heat-cure them to obtain the bamboo bundle shells;

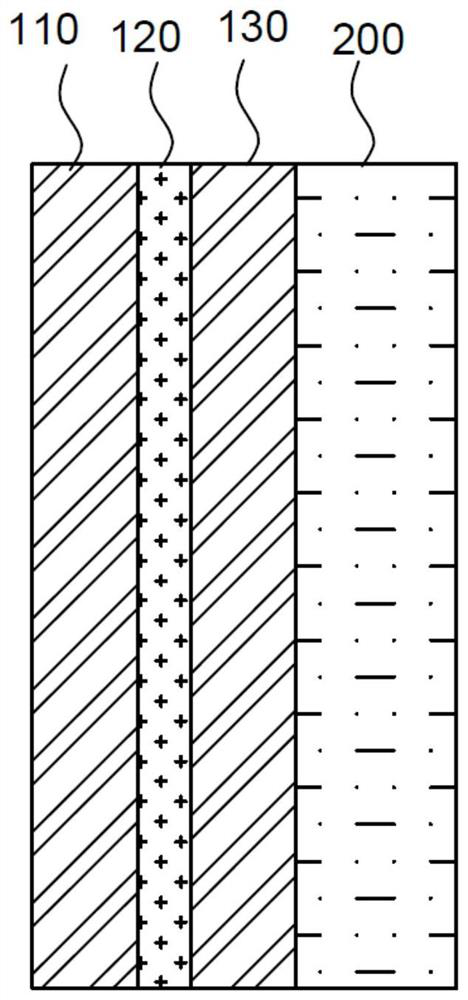

[0026] 3) pave the inside of the molded bamboo bundle shell with an adhesive, bond the glass fiber cloth, then place it in the mold, continue to place the bamboo bundle in step 1) on the inside of the glass fiber cloth, after High-temperature, high-pressure thermosetting molding to obtain a recombined bamboo-glass fiber composite shell;

[0027] 4) Mix 50 parts of steel slag modified phosphogypsum, 10 parts of diatom mud, 30 parts of ordinary portland cement, 5 parts of fly ash, 3 parts of resin foaming agent, 1 part of polycarboxylate superplasticizer, 1 part of Carbonate cement activator and 65 parts of water are compounded and foamed to make foamed concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com