Ultra-thin and high-strength modified lithium-ion battery separator and preparation method thereof

A lithium-ion battery, high-strength technology, used in secondary batteries, battery pack components, circuits, etc., can solve the problems of poor liquid retention, easy to be broken down by electrolyte wettability, etc., achieve low thermal shrinkage, high Mechanical strength and heat resistance, the effect of good mechanical strength and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

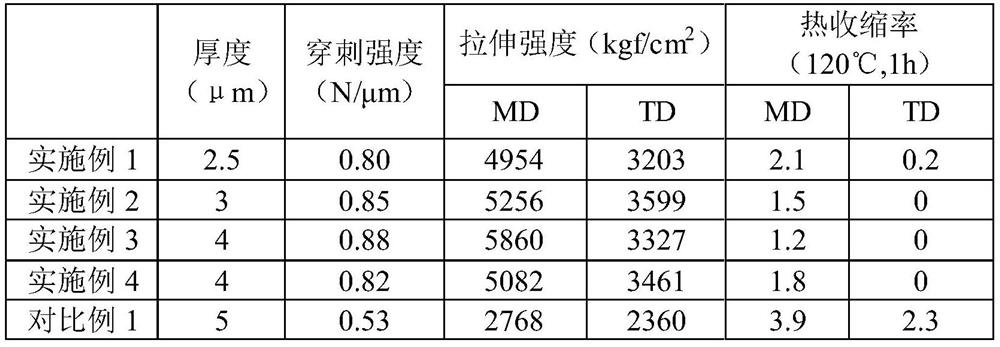

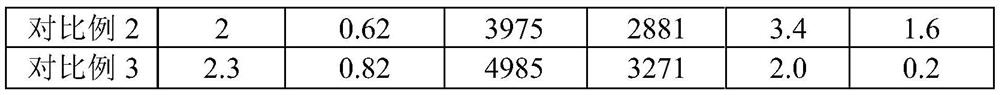

Examples

Embodiment 1

[0026] The preparation method of ultra-thin and high-strength modified lithium ion battery separator comprises the following steps:

[0027] (1) 60 parts by weight of ultra-high molecular weight polyethylene, 40 parts by weight of ultra-high molecular weight polyethylene, 5 parts by weight of silane coupling modified fumed silica, 0.1 part by weight of antioxidant, 400 parts by weight of The white oil is evenly mixed to obtain a mixture;

[0028] (2) The mixture is transported to a screw extruder, melted and extruded at 200°C, and a thick sheet is obtained by casting, and then the thick sheet is stretched 10 times longitudinally to obtain a thin sheet, and then transversely Stretching 9 times to obtain an oil-containing film, placing the oil-containing film in dichloromethane for extraction of white oil, drying to obtain a dry film, and then stretching the dry film horizontally by 1.2 times again to obtain a microporous film. The ultra-thin microporous membrane is obtained by...

Embodiment 2

[0031] The preparation method of ultra-thin and high-strength modified lithium ion battery separator comprises the following steps:

[0032] (1) 70 parts by weight of ultra-high molecular weight polyethylene, 30 parts by weight of ultra-high molecular weight polyethylene, 10 parts by weight of silane coupling modified fumed silica, 0.3 parts by weight of antioxidant, 300 parts by weight of The white oil is evenly mixed to obtain a mixture;

[0033] (2) The mixture is transported to a screw extruder, melted and extruded at 220° C. to obtain a thick sheet by casting, and then the thick sheet is longitudinally stretched by 12 times to obtain a thin sheet, and then transversely Stretching 10 times to obtain an oil-containing film, placing the oil-containing film in dichloromethane for extraction of white oil, drying to obtain a dry film, and then stretching the dry film horizontally by 1.1 times again to obtain a microporous film. The ultra-thin microporous membrane is obtained by ...

Embodiment 3

[0036] (1) 80 parts by weight of ultra-high molecular weight polyethylene, 20 parts by weight of ultra-high molecular weight polyethylene, 8 parts by weight of silane coupling modified fumed silica, 0.5 parts by weight of antioxidant, 350 parts by weight of The white oil is evenly mixed to obtain a mixture;

[0037] (2) The mixture is transported to a screw extruder, melted and extruded at 210°C, and a thick sheet is obtained by casting, and then the thick sheet is stretched 15 times longitudinally to obtain a thin sheet, and then transversely Stretching 13 times to obtain an oil-containing film, placing the oil-containing film in dichloromethane for extraction of white oil, drying to obtain a dry film, and then stretching the dry film horizontally by 1.1 times again to obtain a microporous film. The ultra-thin microporous membrane is obtained by pulling first through a hot roller at 100 °C, then through a cold roller below 30 °C for shaping, winding and slitting;

[0038] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com