Solar light absorption coating and preparation method thereof

A technology of light-absorbing coating and solar energy, applied in the field of solar heat collecting materials, can solve the problems of unsuitable coating and high preparation cost, and achieve the effects of reducing preparation difficulty, convenient and simple process, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

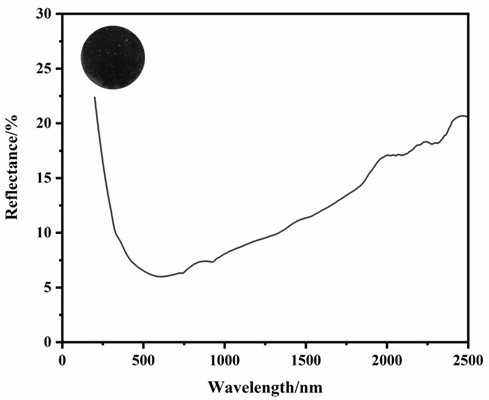

Embodiment 1

[0022] 1) Weigh Co(NO 3 ) 2 ·6H 2 O crystal 5.82 g, Ni(NO 3 ) 2 ·6H 2 O crystal 2.62 g, Fe(NO 3 ) 3 9H 2 O crystal 0.40 g, put the three crystals into a 250 mL beaker, add 100 mL of absolute ethanol and stir thoroughly until the crystals are completely dissolved, and place the mixed solution in a 70 °C water bath to volatilize until only 10 mL remains;

[0023] 2) Take 3 g of the sol obtained after volatilization in a beaker, add 0.5 g of polyethylene glycol-400, and transfer the mixed solution to the spray gun after fully stirring, adjust the spray gun pressure to 0.4 MPa, the spraying angle to 90°, and the spraying speed to 0.15 m / s, spray the mixed solution on the polished 304 stainless steel substrate, and the number of sprayed layers is 2 layers;

[0024] 3) Put the sprayed sample in a 70 °C oven for 30 min, take it out, transfer it to a muffle furnace, set the heating rate at 5 °C / min, heat it up to 500 °C for 1 h, and then cool it to room temperature with the fu...

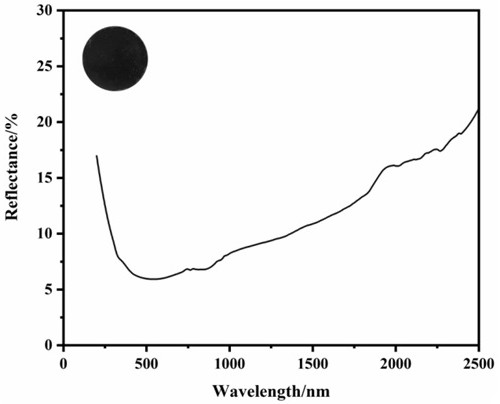

Embodiment 2

[0028] 1) Weigh Co(NO 3 ) 2 ·6H 2 O crystal 11.64 g, Ni(NO 3 ) 2 ·6H 2 O crystal 5.24 g, Fe(NO 3 ) 3 9H 2 O crystal 0.80 g, put the three crystals into a 250 mL beaker, add 150 mL of absolute ethanol and stir thoroughly until the crystals are completely dissolved, then place the mixed solution in a water bath at 75 °C to evaporate until only 24 mL remains;

[0029] 2) Take 3 g of the sol obtained after volatilization in a beaker, add 0.6 g of polyethylene glycol-400, and transfer the mixed solution to the spray gun after fully stirring. 0.15 m / s, spray the mixed solution on the polished 304 stainless steel substrate, and the number of sprayed layers is 2 layers;

[0030] 3) Put the sprayed sample in a 70 °C oven for 30 min, take it out, transfer it to a muffle furnace, set the heating rate at 5 °C / min, heat it up to 500 °C for 1 h, and then cool it to room temperature with the furnace Then take it out.

[0031] The emissivity performance of the coating prepared in th...

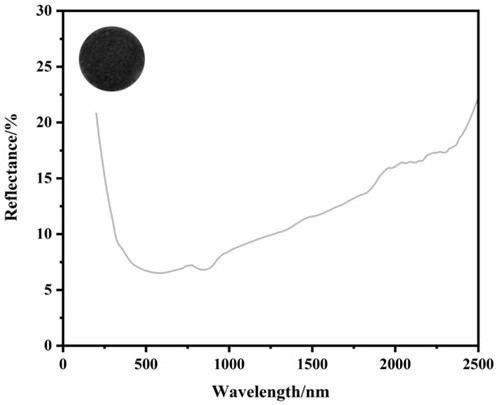

Embodiment 3

[0034] 1) Weigh Co(NO 3 ) 2 ·6H 2 O crystal 5.82 g, Ni(NO 3 ) 2 ·6H 2 O crystal 2.62 g, Fe(NO 3 ) 3 9H 2 O crystal 0.40 g, put the three kinds of crystals into a 250 mL beaker, add 100 mL of absolute ethanol and stir thoroughly until the crystals are completely dissolved, and place the mixed solution in a 70 °C water bath to volatilize until only 15 mL remains;

[0035] 2) Take 3 g of the sol obtained after volatilization in a beaker, add 0.5 g of polyethylene glycol-400, and transfer the mixed solution to the spray gun after fully stirring, adjust the spray gun pressure to 0.4 MPa, the spraying angle to 90°, and the spraying speed to 0.15 m / s, spray the mixed solution on the polished 304 stainless steel substrate, and the number of sprayed layers is 3 layers;

[0036] 3) Put the sprayed sample in a 70 °C oven for 30 min, take it out, transfer it to a muffle furnace, set the heating rate at 5 °C / min, heat it up to 500 °C for 1 h, and then cool it to room temperature wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com