Preparation method of high-quality tellurium quantum dots

A tellurium quantum, high-quality technology, applied in the field of preparation of high-quality tellurium quantum dots, to achieve the effect of low cost, high yield and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A preparation method of high-quality tellurium quantum dots, comprising the following steps:

[0013] 1) Grind 100 mg of tellurium elemental powder in a mortar;

[0014] 2) Put the ground tellurium powder into a 250ml beaker, add 100ml of water, and mix evenly to obtain a mixed solution;

[0015] 3) Perform ultrasonic peeling on the mixture, the ultrasonic time is 10h, and the ultrasonic power is 800W;

[0016] 4) Finally, the product after ultrasonic stripping is subjected to centrifugal classification, and the rotational speed of centrifugal classification is 10,000 rpm to obtain tellurium quantum dots.

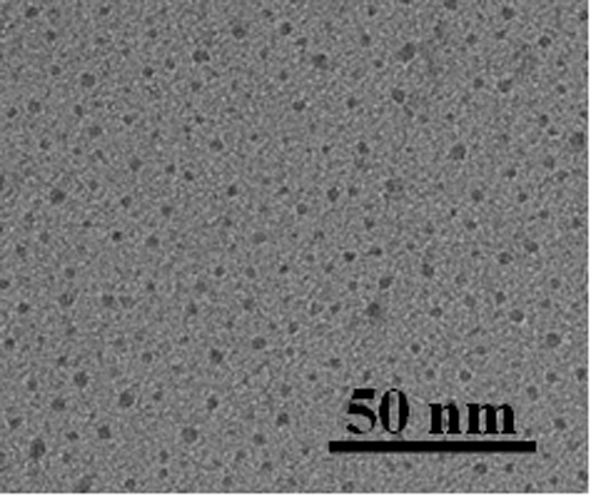

[0017] figure 1 The transmission electron micrograph of the tellurium quantum dot prepared for the present embodiment, by figure 1 It can be seen that the size of the tellurium quantum dots is uniform.

Embodiment 2

[0019] A preparation method of high-quality tellurium quantum dots, comprising the following steps:

[0020] 1) Grind 50 mg of tellurium elemental powder in a mortar;

[0021] 2) Put the ground tellurium powder into a 250ml beaker, add 100ml of 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid, and mix evenly to prepare a mixed solution;

[0022] 3) Perform ultrasonic peeling on the mixture, the ultrasonic time is 20h, and the ultrasonic power is 500W;

[0023] 4) Finally, the products after ultrasonic stripping were subjected to centrifugal classification, and the rotational speed of the centrifugal classification was 11,000 rpm to obtain tellurium quantum dots.

Embodiment 3

[0025] A preparation method of high-quality tellurium quantum dots, comprising the following steps:

[0026] 1) Grind 70 mg of tellurium elemental powder in a mortar;

[0027] 2) Put the ground tellurium powder into a 250ml beaker, add 100ml of N-methylpyrrolidone solution, and mix evenly to prepare a mixed solution;

[0028] 3) Perform ultrasonic peeling on the mixture, the ultrasonic time is 15h, and the ultrasonic power is 900W;

[0029] 4) Finally, the product after ultrasonic stripping was subjected to centrifugal classification, and the rotational speed of the centrifugal classification was 15,000 rpm to obtain tellurium quantum dots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com