Composition for polymer gel, gel prepared from composition and application of gel

A technology of polymer gels and polymer compounds, applied in applications, household appliances, types of adhesives, etc., can solve the problems of less attention and research on the conformation and distribution of polymer chains, and achieve the best mechanical properties, excellent Adhesive performance, high transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0049] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0051] Weigh 0.9 g of PVA, dissolve in 10 mL of DMSO under heating at 95° C., and stir for 3 hours to ensure uniform dissolution. After removing air bubbles, pour the transparent and clear solution into a PTFE mold, cover the surface with a glass sheet, and then immerse in a large amount of excess water at room temperature for 48 hours of solvent replacement to form a hydrogel, which is recorded as PVA exogel-9.

[0052] The obtained PVA exogel-9 hydrogel is tested for tensile mechanical properties, the sample is dumbbell-shaped (17mm long, 4mm wide, 2mm thick), the tensile rate is 50mm / min, and the tensile modulus is 0.10 ± 0.02MPa, The tensile strength is 0.58±0.16MPa. The resulting PVA exogel-9 hydrogel was subjected to a fracture toughness test. The sample was a rectangle (length 5mm, width 20mm, thickness 1mm), the tensile rate was 50mm / min, and the fracture toughness was 0.66±0.03kJ / m 2 .

[0053] After the obtained PVA exogel-9 hydrogel was swelled in water for 7 day...

Embodiment 2

[0055] Weigh 1.8g of PVA, dissolve in 10mL DMSO under heating at 95°C, and stir for 3 hours to ensure uniform dissolution. After removing air bubbles, pour the transparent and clear solution into a PTFE mold, cover the surface with a glass sheet, and then immerse in a large amount of excess water at room temperature for 48 hours of solvent replacement to form a hydrogel, which is recorded as PVA exogel-18.

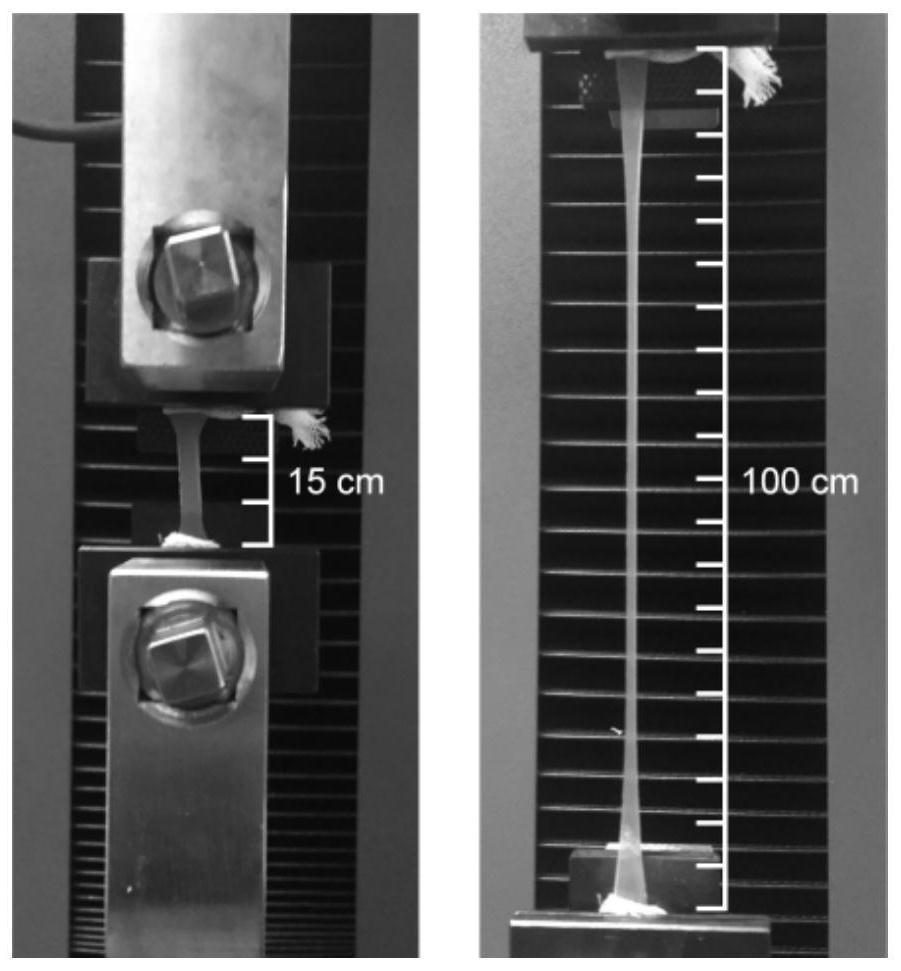

[0056] Such as figure 1 It can be seen that PVA exogel-18 hydrogel has excellent tensile properties and can be stretched to more than 6 times its original length without breaking.

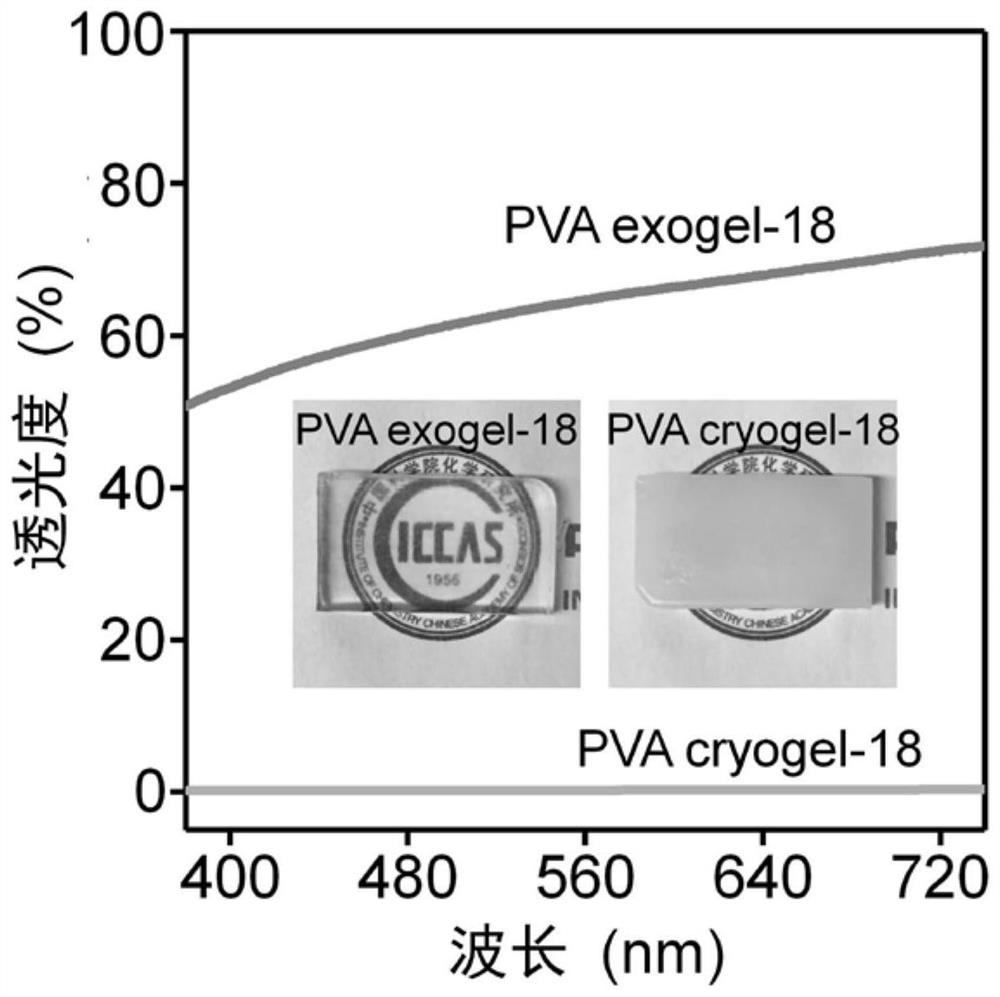

[0057] Such as figure 2 As shown, PVA exogel-18 hydrogel has high transparency.

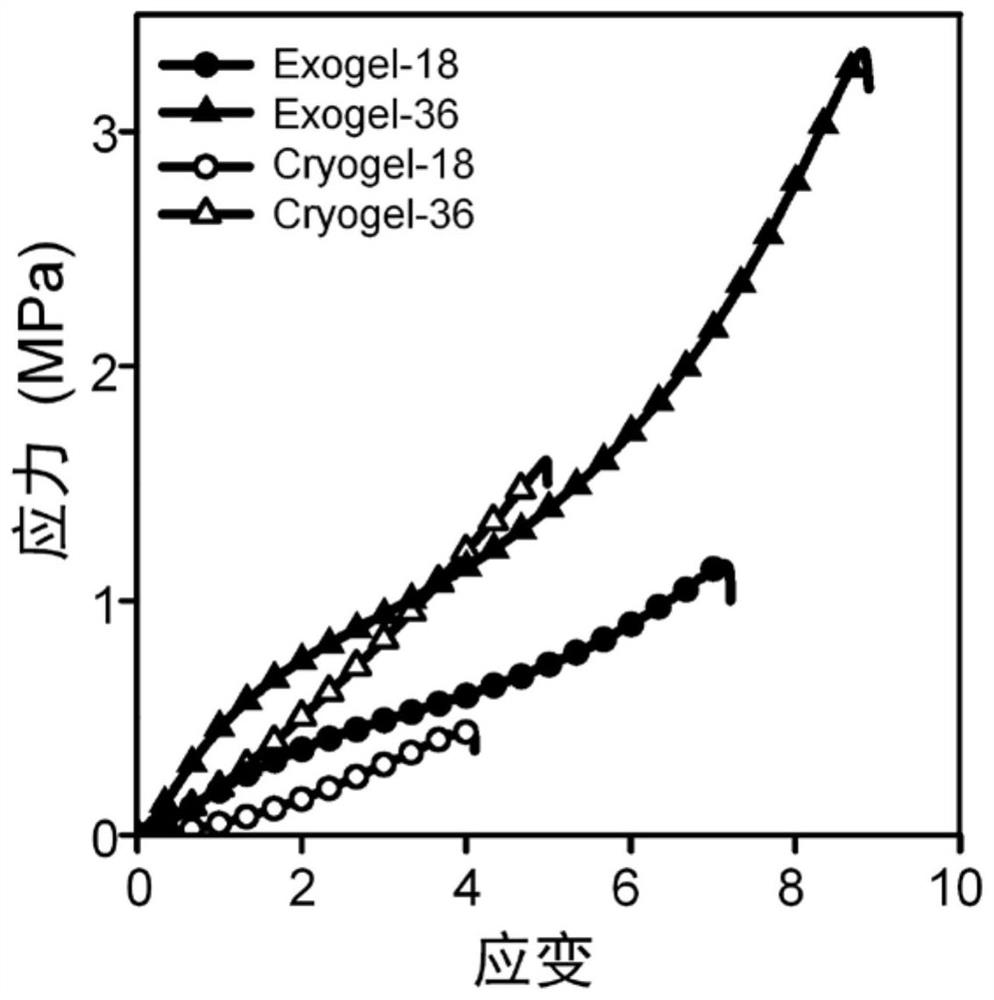

[0058] The PVA exogel-18 hydrogel that obtains is carried out tensile mechanical property test, and sample is dumbbell shape (long 17mm, wide 4mm, thick 2mm), and tensile rate is 50mm / min, and stress-strain curve is as follows image 3 As shown, the tensile modulus is 0.18±0.01MPa, and the tensile strength is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com