Long-acting anti-icing coating as well as preparation method and application thereof

An anti-icing and coating technology, used in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc. problems, to achieve the effect of reducing the friction coefficient, delaying volatilization, and good wear resistance of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, a modified nano-silica nano-solution is used. Include the following steps:

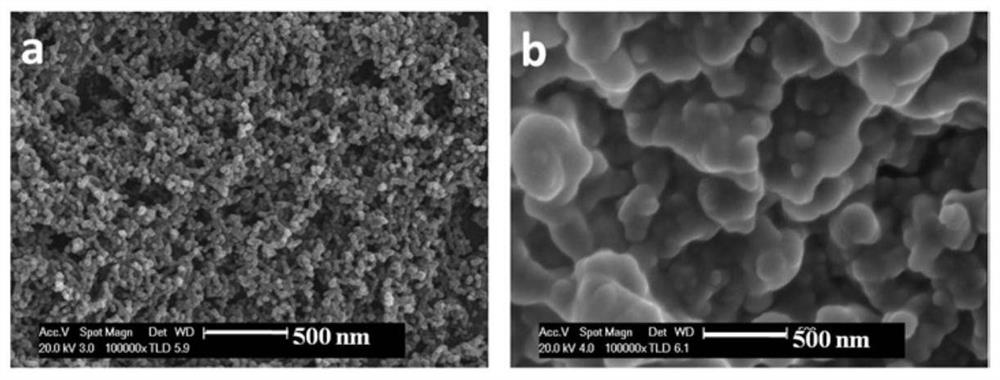

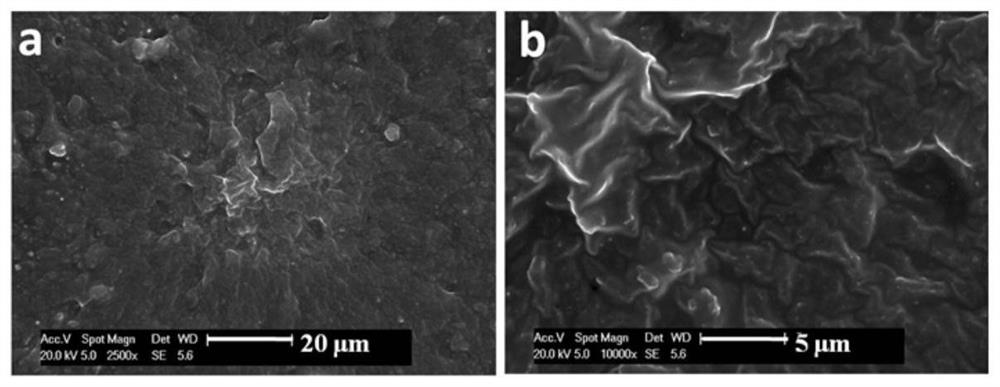

[0029] (1) Preparation of modified porous silica powder: mix ethanol, deionized water, and ammonia water in a ratio of 20:4:1, stir evenly, add 1vol.% nano-chain silica sol solution dropwise, and then add 0.6vol.% TEOS is used as a cross-linking agent, and then 0.6vol.% n-octyltriethoxysilane is added for surface modification. Finally, the beaker is sealed and stirred for 24 hours to obtain modified nano-SiO 2 solution. Move the solution into an oven at 120°C, dry it completely, and sieve it with a 200-mesh sieve to obtain the modified porous powder;

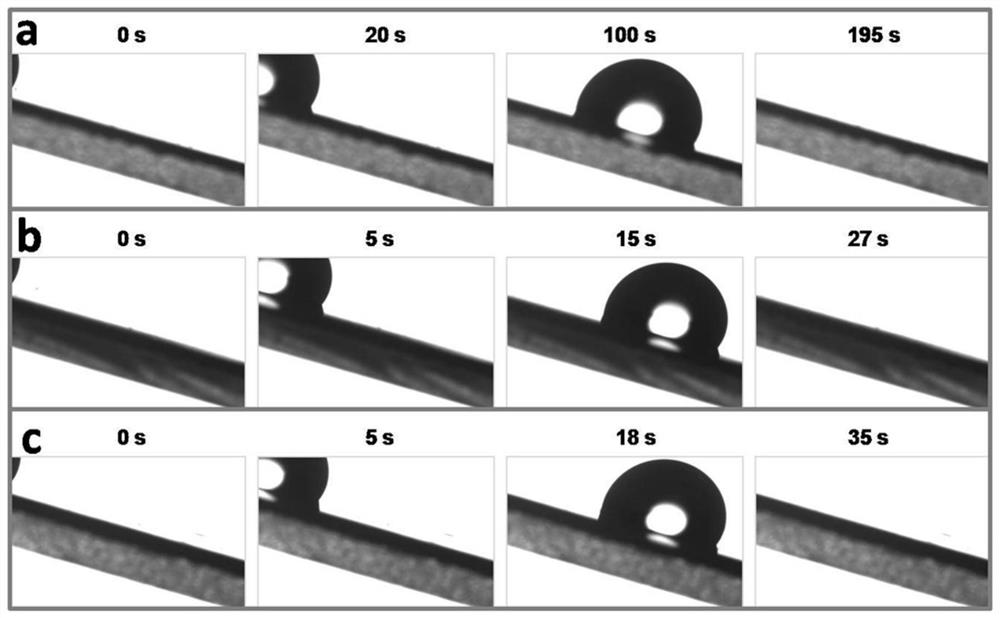

[0030] (2) Preparation of oil storage powder: Mix 1 g of the modified porous powder prepared in step (1) with 4 g of simethicone oil with a viscosity of 500 CS, stir thoroughly for 10 min, then place it in an autoclave and pressurize to 0.5MPa, keep for 10 minutes, and then ultrasonic for 10 minutes, you can get the oil sto...

Embodiment 2

[0037] In this embodiment, a modified silicon dioxide nanometer solution is used. Include the following steps:

[0038] (1) Preparation of modified porous silica powder: mix ethanol, deionized water, and ammonia water in a ratio of 20:4:1, stir evenly, add 1vol.% nano-chain silica sol solution dropwise, and then add 0.6vol.% TEOS is used as a cross-linking agent, and then 0.6vol.% n-octyltriethoxysilane is added for surface modification. Finally, the beaker is sealed and stirred for 24 hours to obtain modified nano-SiO 2 solution. Move the solution into an oven at 120°C, dry it completely, and sieve it with a 200-mesh sieve to obtain the modified porous powder;

[0039] (2) Preparation of anti-icing coating: mix 10g of butyl acetate and 10g of fluorocarbon resin to obtain a resin solution, then add the modified porous powder prepared in step (1) to the resin solution, ultrasonically mix for 1min, and mix Add 3.33g polyisocyanate in the solution as curing agent, then stir to...

Embodiment 3

[0045] In this embodiment, a modified nano-silica nano-solution is used. Include the following steps:

[0046] (1) Preparation of modified porous silica powder: mix ethanol, deionized water, and ammonia water in a ratio of 20:4:1, add 1vol.% nano-chain silica sol solution dropwise after stirring evenly, and then Add 0.6vol.% TEOS as a cross-linking agent, then add 0.6vol.% n-octyltriethoxysilane for surface modification, and finally, seal the beaker and stir for 24 hours to obtain modified nano-SiO 2 solution. Move the solution into an oven at 120°C, dry it completely, and sieve it with a 200-mesh sieve to obtain the modified porous powder;

[0047] (2) Preparation of oil storage powder: Mix 1 g of modified porous powder prepared in step (1) with 8 g of simethicone oil with a viscosity of 500 CS, stir thoroughly for 10 min, then place it in an autoclave and pressurize to 0.5MPa, keep for 10 minutes, and then ultrasonic for 10 minutes, you can get the oil storage powder.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com