A kind of water-based reflective heat-insulating coating and its preparation method and application

A reflective thermal insulation coating, water-based technology, applied in reflective/signal coatings, coatings, roofs using sealing aggregates, etc., can solve the problems of large construction scale, high indoor temperature comfort and energy saving requirements, and achieve energy saving Consumption promotion, avoiding the reduction of reflection effect, reducing the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Water-based reflective insulation coating

[0050] In this example, the prepared water-based reflective heat-insulating coating is made of the following components in parts by weight: 30 parts of fluorosilicon emulsion, 35 parts of silicon acrylic emulsion, 3 parts of hollow ceramic microspheres, 3 parts of phase change particles 3 parts of nano-airgel powder, 20 parts of nano-titanium dioxide, 0.35 parts of water-based floating aluminum-silver paste, 0.35 parts of water-based non-leafing aluminum-silver paste, 1.5 parts of dispersant, 1.5 parts of defoamer, and 1.5 parts of rheology additive part, 0.8 part of antibacterial agent;

[0051] Its preparation method is as follows:

[0052] Put fluorosilicon emulsion, silicon acrylic emulsion, water-based floating aluminum-silver paste, water-based non-leafing aluminum-silver paste, film-forming aids, and antibacterial agents in a container, and disperse them for 14 minutes at a stirring rate of 1200r / min to obt...

Embodiment 2 to 6 and comparative example 1 to 5

[0053] Examples 2 to 6 and comparative examples 1 to 5: Water-based reflective insulation coating

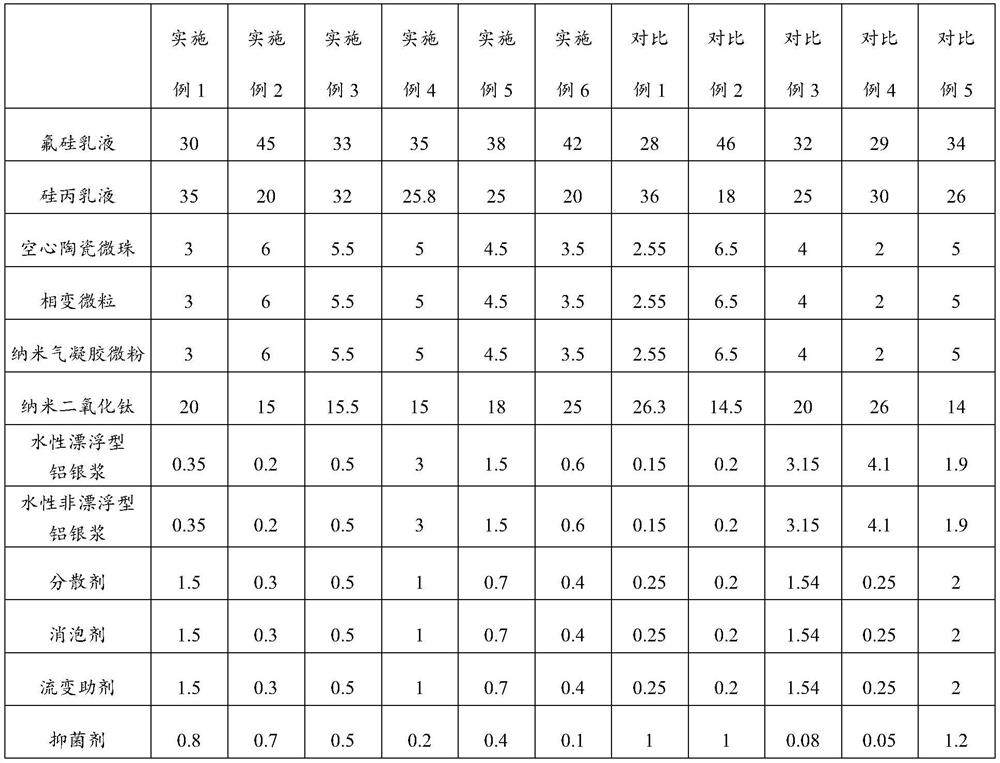

[0054] Examples 2 to 6 and Comparative Examples 1 to 5 were all prepared according to the preparation method in Example 1, and the specific component compositions are shown in Table 1.

[0055] Table 1: Component compositions contained in the water-based reflective heat-insulating coatings prepared in Examples 1-6 and Comparative Examples 1-5.

[0056]

Embodiment 7

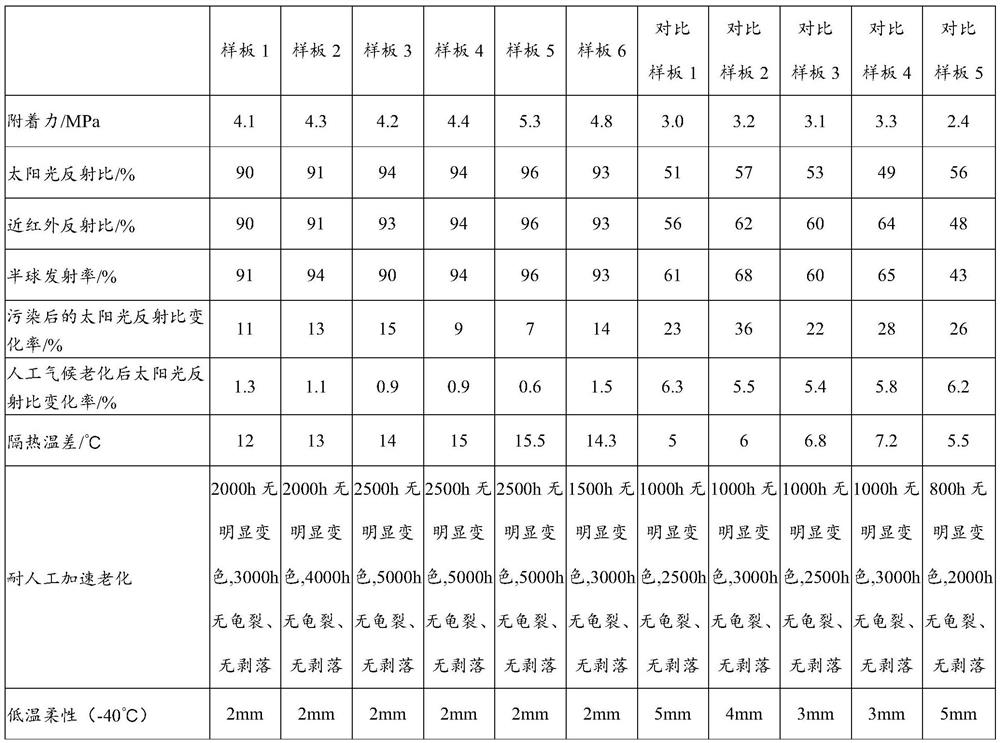

[0057] Embodiment 7: performance test

[0058] 1. Preparation of test samples

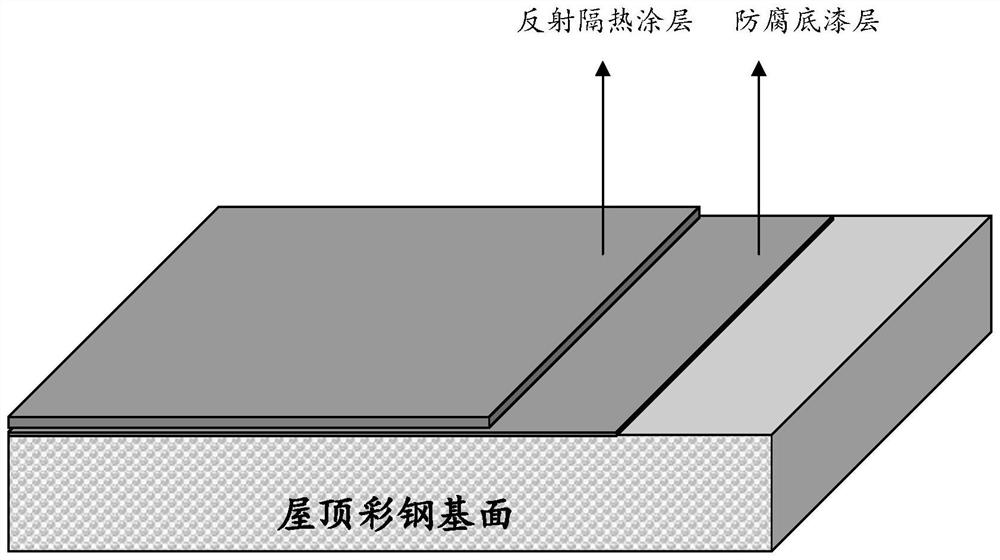

[0059] In order to better simulate the actual application conditions, this example adopts the heat insulation system of "anti-corrosion primer layer + reflective heat-insulation coating" for performance testing. The test sample is a 3mm sandblasted steel plate, and the anti-corrosion primer is ZD800 (W) water-based Epoxy zinc-rich primer (Tianjin Shuangshi Paint Co., Ltd.), according to different test requirements, scrape reflective heat-insulating coating for performance testing, among which the matching reflective heat-insulating coating for salt spray resistance and sunlight reflection ability test The layer thickness was 1.0 mm.

[0060] The method of preparing the test sample of the reflective thermal insulation coating is as follows:

[0061] Step 1: Clean up the floating dust and dirt on the surface of the base surface, and spray the anti-corrosion primer after the surface is dry;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com