Plugging material and preparation method thereof

A technology of plugging materials and surfactants, which is applied in the field of drilling and completion engineering, can solve problems such as unadjustable curing time, and achieve the effect of satisfying reservoir protection requirements and satisfying leakage control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

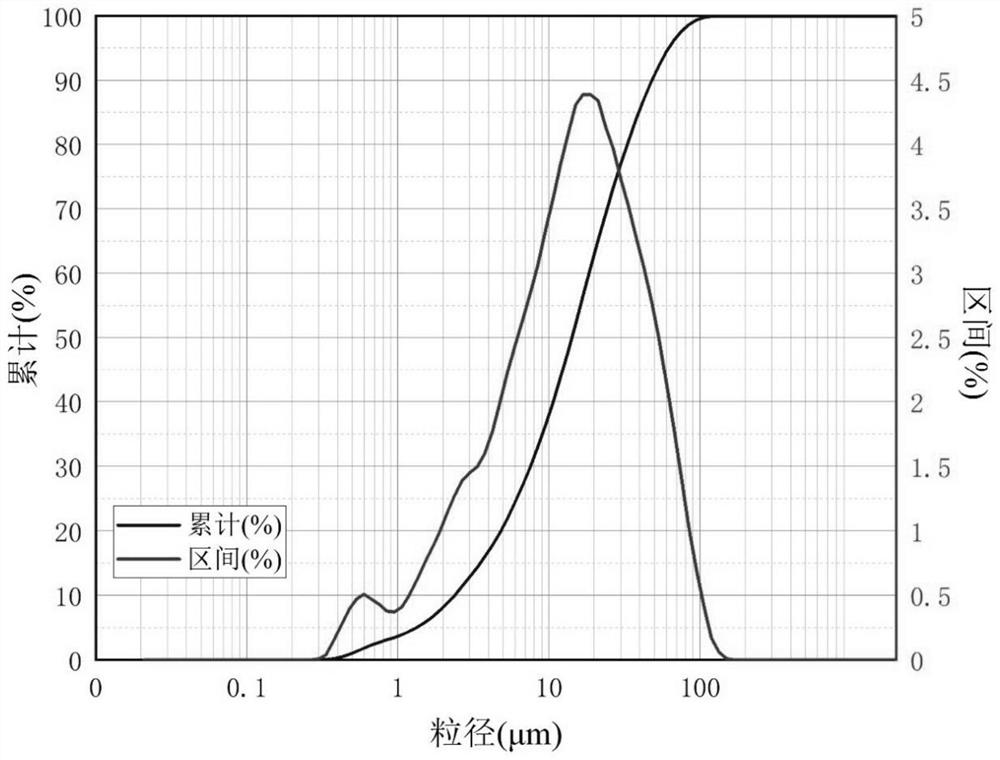

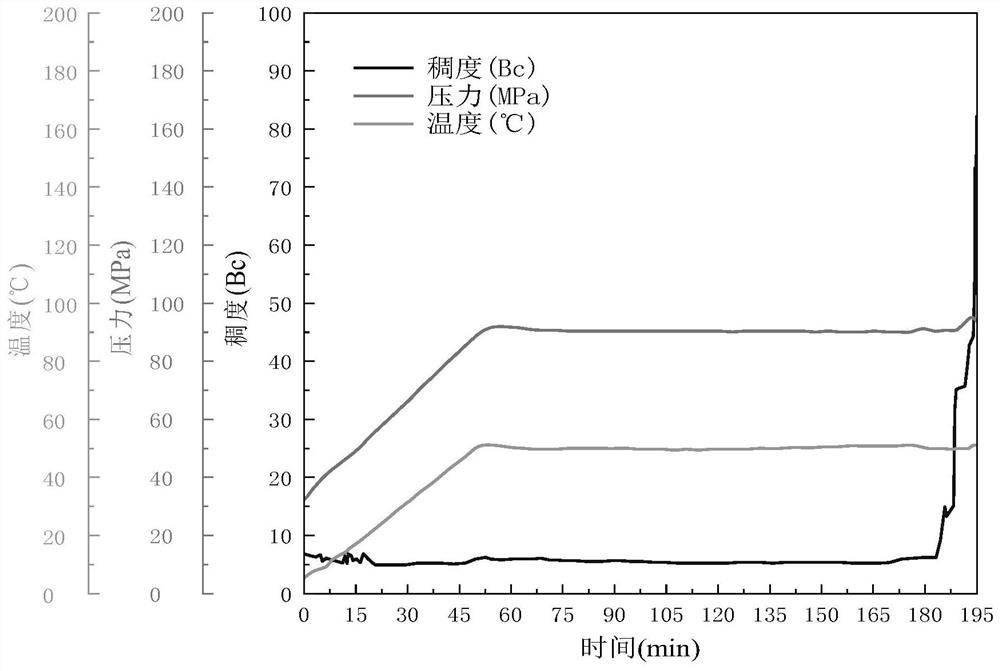

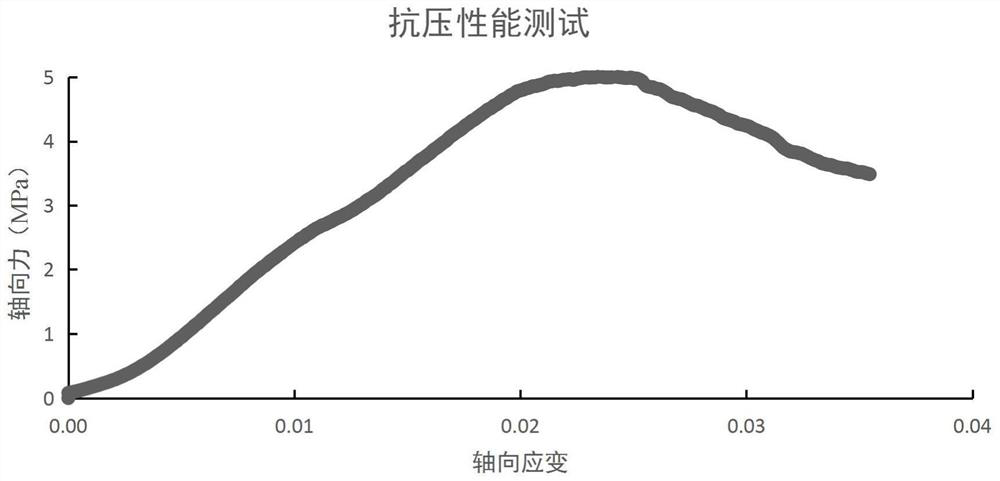

[0037] A plugging material, which is composed of the following components in mass percentage: 0.12% of Span 80, 0.12% of Pingpinga O-20, 4% of diesel oil, 0.16% of polyvinyl alcohol, 20% of calcium chloride, 4% sodium bicarbonate, 28% dolomite powder, 1.6% starch, 4% sodium phosphate, 38% water.

[0038]The plugging material is prepared by the following steps: add part of water to the slurry mixing container, turn on the agitator, then add part of sodium phosphate, and at the same time, dissolve Span 80 in diesel oil and add it to the water phase, and stir evenly Obtain the water-in-oil type inner layer retarder; Add remaining water, flatly add O-20, remaining sodium phosphate, starch, sodium bicarbonate in the described water-in-oil type inner layer retarder, wait for it to stir about After fully dissolving in 2 minutes, add polyvinyl alcohol, stir for about 30 minutes, until the polyvinyl alcohol is completely dissolved, add calcium chloride and dolomite mineral powder to th...

Embodiment 2

[0040] A plugging material, which is composed of the following components in mass percentage: 0.12% of Span 80, 0.12% of polyoxyethylene ether, 4% of kerosene, 0.16% of polyvinyl alcohol, 20% of calcium chloride, 4% % sodium bicarbonate, 28% dolomite powder, 1.6% starch, 4% sodium phosphate, 38% water.

[0041] The plugging material is prepared by the following steps: add part of water to the slurry mixing container, turn on the agitator, then add part of sodium phosphate, at the same time, dissolve Span 80 in kerosene and add it to the water phase, and stir evenly Obtain the water-in-oil type inner layer retarder; Add remaining water, polyoxyethylene ether, remaining sodium phosphate, starch, sodium bicarbonate to the described water-in-oil type inner layer retarder, and wait for it to stir for about 2 Add polyvinyl alcohol after fully dissolving in 1 minute, stir for about 30 minutes, until the polyvinyl alcohol is completely dissolved, add calcium chloride and dolomite mine...

Embodiment 3

[0043] A plugging material, which is composed of the following components in mass percentage: 0.11% Span 80, 0.11% Pingpinga O-20, 3.7% diesel oil, 0.15% polyvinyl alcohol, 18.52% calcium chloride, 3.7% Sodium bicarbonate, 29.63% dolomite mineral powder, 1.48% starch, 7.41% sodium phosphate, 35.19% clear water.

[0044] The plugging material is prepared by the following steps: add part of water to the slurry mixing container, turn on the agitator, then add part of sodium phosphate, and at the same time, dissolve Span 80 in diesel oil and add it to the water phase, and stir evenly Obtain the water-in-oil type inner layer retarder; Add remaining water, flatly add O-20, remaining sodium phosphate, starch, sodium bicarbonate in the described water-in-oil type inner layer retarder, wait for it to stir about After fully dissolving in 3 minutes, add polyvinyl alcohol, stir for about 30 minutes, until the polyvinyl alcohol is completely dissolved, add calcium chloride and dolomite min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com