Method for determining content of halogenated acid in chloral hydrate or preparation thereof

A technology of chloral hydrate and halogenated acid, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as the determination method of halogenated acid content in unrecorded chloral hydrate preparations, and avoid factors that interfere with the test results , high sensitivity and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

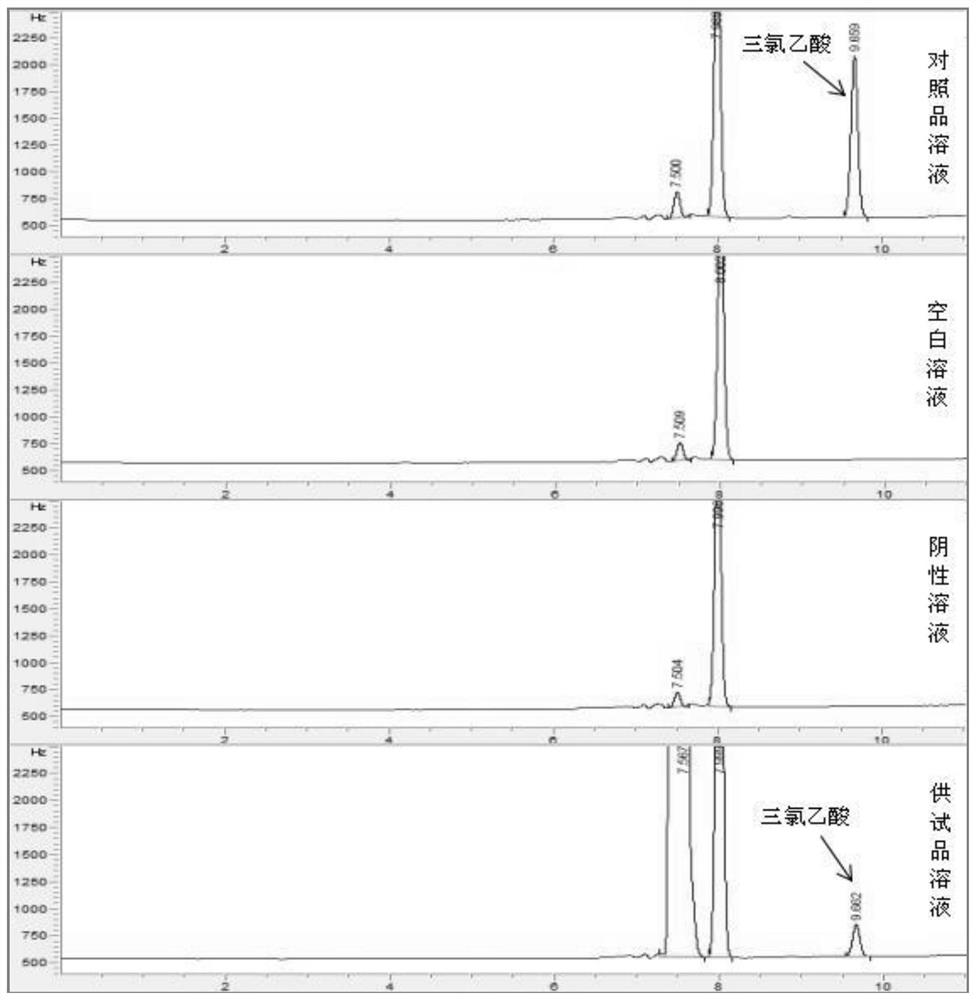

[0060] The detection method of embodiment 1 trichloroacetic acid and dichloroacetic acid

[0061] 1.1 Instruments and reagents

[0062] Instruments: gas chromatograph, GC-2014, Shimadzu Corporation, Japan; 7890B, Agilent Corporation, USA; electronic analytical balance, CPA225D, Sartorius Scientific Instrument Co., Ltd., etc.

[0063] Reagents: reference substance dichloroacetic acid, content 98.4%, purchased from Dr.Ehrenstorfer GmbH, reference substance trichloroacetic acid, content ≥99.0%, purchased from Tokyo Chemical Industry Co., Ltd., methyl tert-butyl ether and methanol are chromatographically pure, The remaining reagents (concentrated sulfuric acid (density 1.84g / mL), anhydrous sodium sulfate, sodium chloride, sodium hydroxide, sodium bicarbonate, etc.) were of analytical grade, and the water was self-made ultrapure water.

[0064] 10% methanolic sulfuric acid solution: Slowly add 5ml of sulfuric acid to 45ml of methanol under stirring, and leave to room temperature. ...

Embodiment 2 3

[0087] Example 2 Trichloroacetic acid detection method verification

[0088] overview

[0089] The method for the detection of TCA was validated and the results of the validation are summarized in Table 1.

[0090] Table 1 Summary of Trichloroacetic Acid Detection Method Validation

[0091]

[0092] specific description

[0093] 2.1 Instruments and reagents

[0094] 2.1.1 Instruments and equipment

[0095] Table 2 Instruments and equipment

[0096] serial number equipment name model manufacturer 1 Gas Chromatograph GC-2014 Shimadzu Corporation 2 Gas Chromatograph 7890B Agilent Corporation 3 Electronic balance CPA225D Sartorius Scientific Instruments Ltd. 4 Electronic balance BSA224S Sartorius Scientific Instruments Ltd. 5 Electric constant temperature water bath DZKW-S-4 Beijing Guangming Medical Instrument Co., Ltd. 6 Electric blast drying oven GZX-9246MBE Shanghai Boxun Industrial Co., Ltd. Med...

Embodiment 3 2

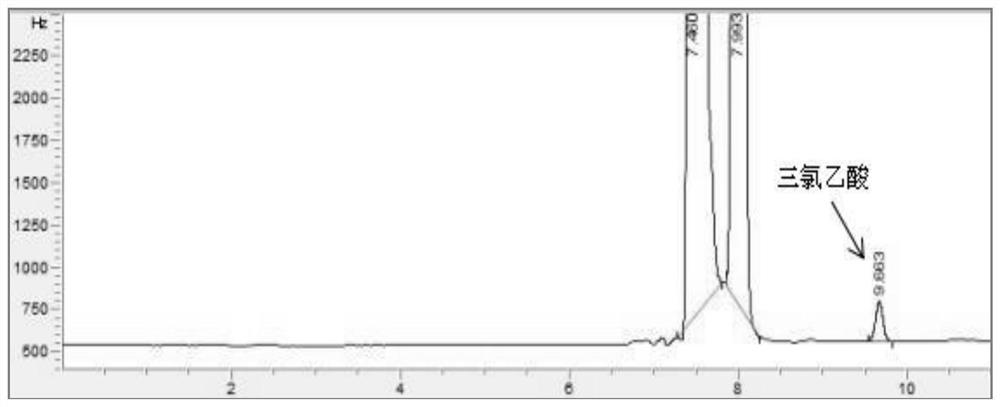

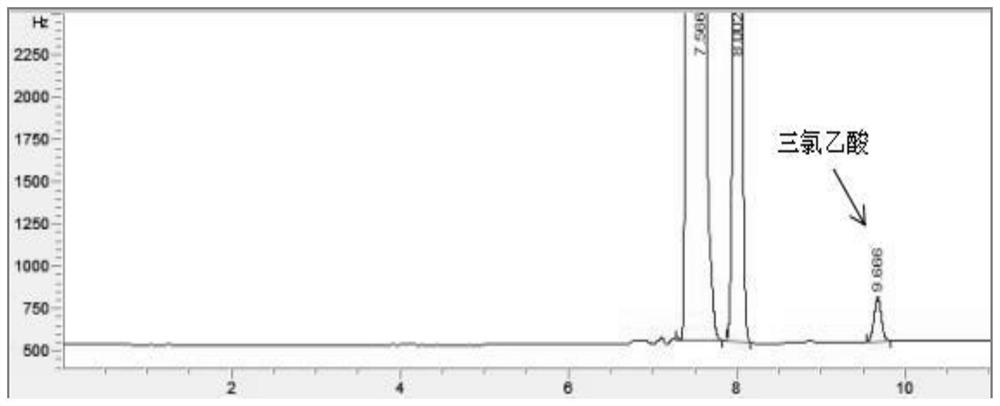

[0187] Embodiment 3 dichloroacetic acid detection method validation

[0188] overview

[0189] The method for the detection of dichloroacetic acid was validated and the results of the validation are summarized in Table 11.

[0190] Table 11 Summary of Dichloroacetic Acid Detection Method Validation

[0191]

[0192] specific description

[0193] 3.1 Instruments and reagents

[0194] 3.1.1 Instruments and equipment

[0195] Table 12 Instruments and equipment

[0196] serial number equipment name model manufacturer 1 Gas Chromatograph 7890B Agilent Corporation 2 Electronic balance CPA225D Sartorius Scientific Instruments Ltd. 3 Electronic balance BSA224S Sartorius Scientific Instruments Ltd. 4 Electric blast drying oven GZX-9246MBE Shanghai Boxun Industrial Co., Ltd. Medical Equipment

[0197] 3.1.2 Reagents

[0198] Chloral hydrate concentrate (74.48%, w / w) (batch number: 20181101, 2181102), Nanjing Tefeng Phar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com