Semiconductor structure and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., to achieve the effect of improving isolation effect, improving production efficiency, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

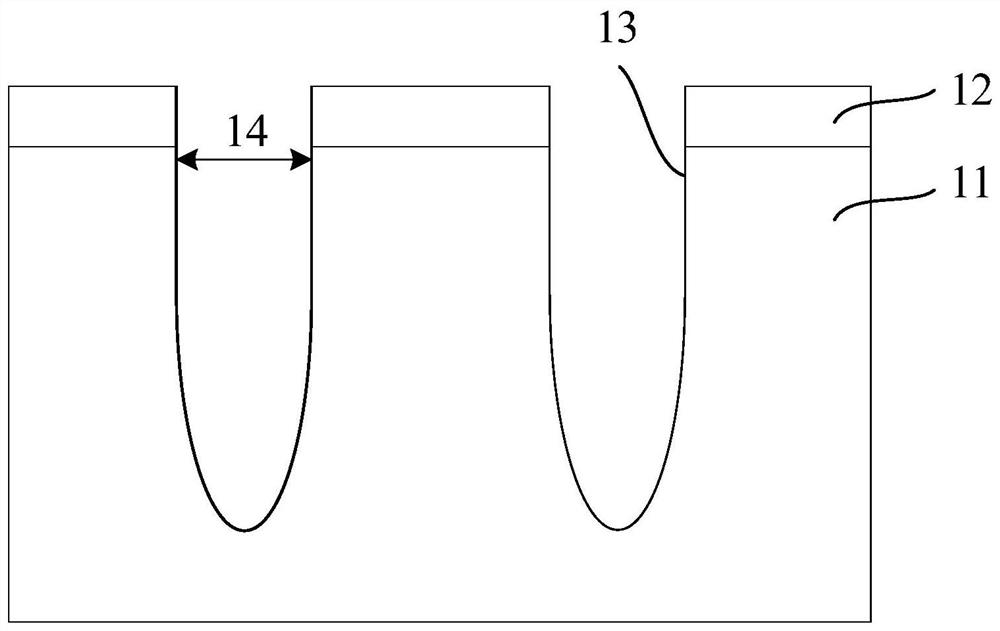

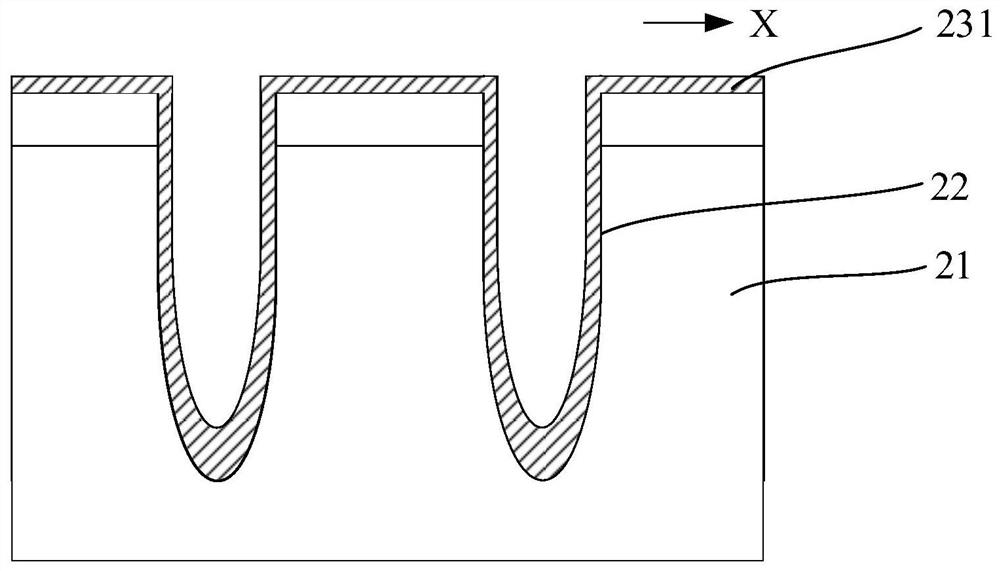

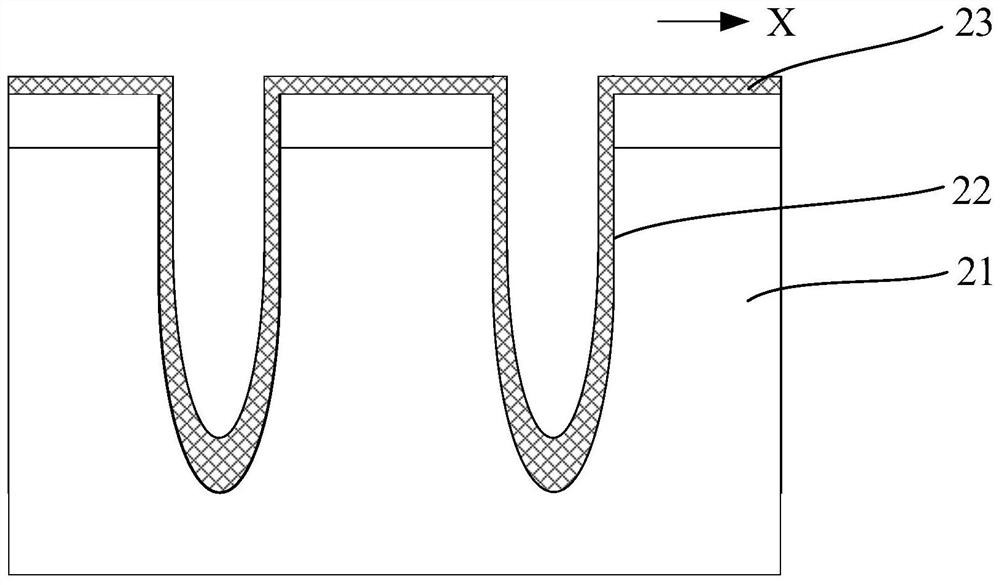

[0028] The manufacturing process of the semiconductor structure includes: after etching a trench with a preset depth and width in the substrate, filling the trench with an insulating substance. Ideally, the insulating substance has good adhesion to the sidewall and bottom of the trench, and the insulating substance attached to the sidewall and bottom of the trench has good compactness, ensuring that ions in the substrate will not diffuse through the isolation structure to adjacent cells, affecting the electrical performance and product yield of the semiconductor structure.

[0029] At present, the main method of manufacturing semiconductor structures is: after etching a trench with a predetermined depth and opening width in the substrate, the plasma enhanced atomic layer deposition (Plasma Enhanced Atomic Layer Deposition, PEALD) is used to fill the trench. insulating substance until the trench opening is closed.

[0030] However, the plasma-enhanced atomic layer deposition p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com