Preparation method of transition metal sulfide nano composite electrode material

A transition metal and nanocomposite technology, which is applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of long preparation time, large size, uneven material shape, etc., and achieve the effect of short preparation time and improved cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

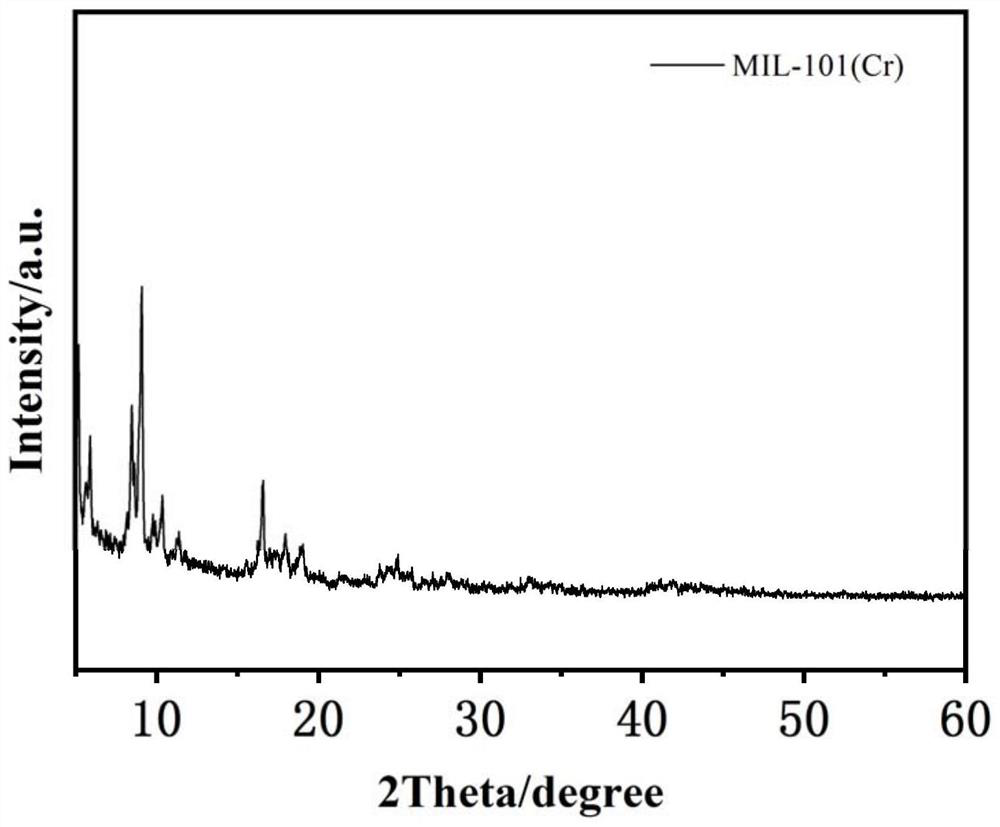

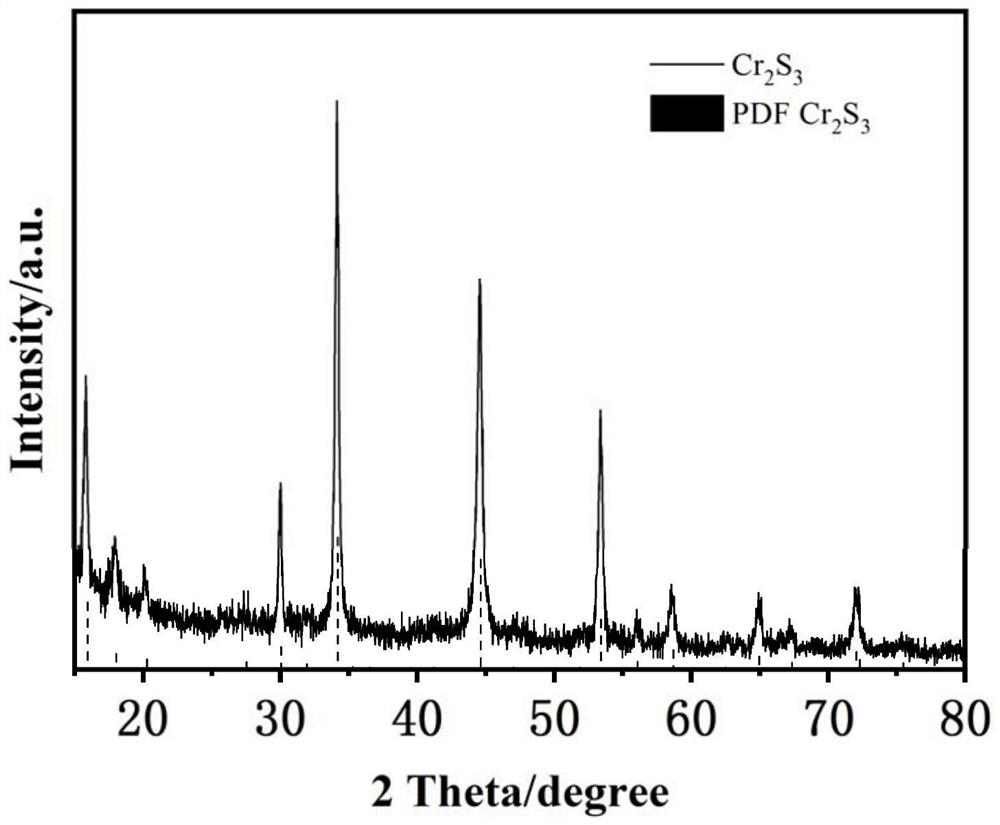

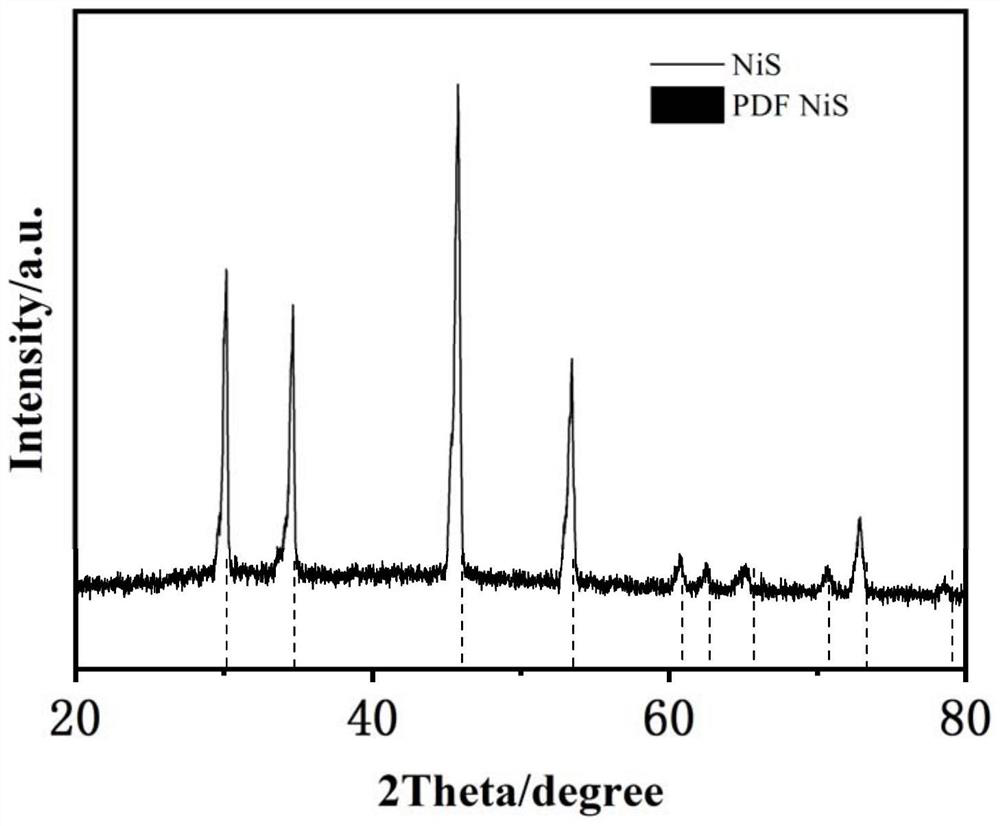

Embodiment 1

[0036] According to metal salt Cr(NO 3 ) 3 9H 2 The molar ratio of O to PTA was 1:1, and 0.1 g of urea was weighed as a nitrogen source. 3.2mmol Cr(NO 3 ) 3 9H 2 Dissolve O and urea in 20mL of deionized water, stir to fully dissolve, adjust the pH to 1 with concentrated HF solution, then put the weighed 3.2mmol of PTA into a microwave hydrothermal reaction tank, and react at 210°C for 0.5 h, after the reaction, the product was washed three times with deionized water. The obtained MOFs precursor was mixed with 20 mL of DMF solution, and the dried MOFs precursor was obtained in an oven at 80 °C. The MOFs precursor powder and sulfur powder were ground and mixed at a mass ratio of 1:3, and a porcelain boat was put into a tube furnace with argon gas for sintering. The sintering temperature was 700 °C and the holding time was 2 h. The mass specific capacity of the prepared material is 450mAh / g.

Embodiment 2

[0038] According to metal salt Cr(NO 3 ) 3 9H 2 The molar ratio of O to PTA was 1:1.5, and 0.1 g of urea was weighed as a nitrogen source. 4.5mmol Cr(NO 3 ) 3 9H 2 Dissolve O and urea in 20mL of deionized water, stir to fully dissolve, adjust the pH to 1 with concentrated HF solution, then put the weighed 3.2mmol of PTA into a microwave hydrothermal reaction tank, and react at 210°C for 0.5 h, after the reaction, the product was washed three times with deionized water. The obtained MOFs precursor was mixed with 20 mL of N,N-dimethylamide solution, and dried in an oven at 80 °C to obtain a dry MOFs precursor. The MOFs precursor powder and sulfur powder were ground and mixed at a mass ratio of 1:3, and a porcelain boat was put into a tube furnace with argon gas for sintering. The sintering temperature was 800 °C and the holding time was 2 h. The mass specific capacity of the prepared material is 550mAh / g.

Embodiment 3

[0040] According to metal salt Cr(NO 3 ) 3 9H 2The molar ratio of O to PTA was 1:1.5, and 0.1 g of urea was weighed as a nitrogen source. 4.5mmol Cr(NO 3 ) 3 9H 2 Dissolve O and urea in 20mL of deionized water, stir to make it fully dissolved, adjust the pH to 1 with concentrated HF solution, then put the weighed 3.2mmol of PTA into a microwave hydrothermal reaction tank, and react at 210°C for 1h After the reaction, the product was washed three times with deionized water. The obtained MOFs precursor was mixed with 20 mL of DMF solution, and the dried MOFs precursor was obtained in an oven at 80 °C. The MOFs precursor powder and sulfur powder were ground and mixed at a mass ratio of 1:3, and a porcelain boat was put into a tube furnace with argon gas for sintering. The sintering temperature was 900 °C and the holding time was 2 h. The mass specific capacity of the prepared material is 450mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com