Expanded perlite insulation board and preparation method thereof

A technology of expanded perlite and thermal insulation board, which is used in thermal insulation, manufacturing tools, building components, etc., can solve the problems of high quality of the board, which is not conducive to large-scale use, low comprehensive cost performance, and long working hours for thermal insulation boards. The effect of reducing dust pollution and shortening the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

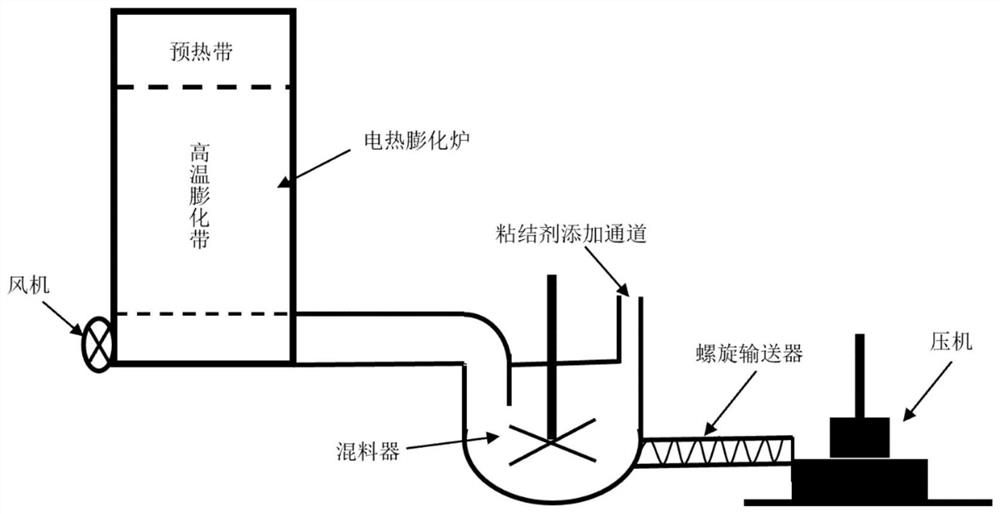

Embodiment 1

[0024] The bulk density is 220kg / m 3 The perlite ore with an average particle size of 2.1mm (Xinyang Shangtianti Mine) is used as raw material, and the mixture of aluminum dihydrogen phosphate and modified tetraethyl orthosilicate is used as a binder to make expanded perlite fireproof and thermal insulation boards . First place the perlite ore in the puffing furnace to preheat. After the water content reaches the puffing requirement, it is puffed at 1100°C, and the expanded perlite is transferred to the mixing bin under the action of wind force; the residual temperature of the expanded perlite during mixing is 90°C, add the mixed solution prepared by the premixed binder and water repellent, mix evenly; transfer the evenly mixed material to the mold through the screw conveyor, the residual temperature of the expanded perlite is 80°C, and the pressure is 1MPa Press down to make expanded perlite insulation board; demould and dry. Its bulk density is 180kg / m 3 , thermal conduct...

Embodiment 2

[0026] The bulk density is 230kg / m 3 The perlite ore with an average particle size of 1.5 mm (Xinyang Shangtianti mine) is used as raw material, and the aluminum dihydrogen phosphate binder is used to make expanded perlite fireproof and thermal insulation boards. First place the perlite ore in the puffing furnace to preheat. After the water content reaches the puffing requirement, it is puffed at 1100°C, and the expanded perlite is transferred to the mixing bin under the action of wind force; the residual temperature of the expanded perlite during mixing is 80°C, add the mixed solution prepared by the premixed binder and water repellent, and mix evenly; transfer the evenly mixed material to the mold through the screw conveyor, and the residual temperature of the expanded perlite is 70°C. Press under pressure to make expanded perlite insulation board; demould and dry. Its bulk density is 200kg / m 3 , thermal conductivity 0.051W / (m·K), compressive strength 0.75MPa, fire perform...

Embodiment 3

[0028] The bulk density is 240kg / m 3 The perlite ore with an average particle size of 0.9 mm (Xinyang Shangtianti mine) is used as raw material, and the modified tetraethyl silicate binder is used to make expanded perlite fireproof and thermal insulation boards. First place the perlite ore in the puffing furnace to preheat. After the water content reaches the puffing requirement, it is puffed at 1200°C, and the expanded perlite is transferred to the mixing bin under the action of wind force; the residual temperature of the expanded perlite during mixing is 80°C, add the mixed solution prepared by the premixed binder and water repellent, and mix evenly; transfer the evenly mixed material to the mold through the screw conveyor, the residual temperature of the expanded perlite is 60°C, and the pressure is 2MPa Press down to make expanded perlite insulation board; demould and dry. Its bulk density is 220kg / m 3 , thermal conductivity 0.058W / (m·K), compressive strength 1.00MPa, fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com