Composite insulator umbrella skirt material and preparation method thereof

A technology of composite insulators and umbrella sheds, which is applied in the field of electrical insulation materials, can solve the problems of low strength, pollution flashover resistance, poor wet flashover ability, easily damaged ceramic/glass insulators without hydrophobicity and hydrophobic migration, and achieve improved Good electrical properties, good interface bonding, and improved storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

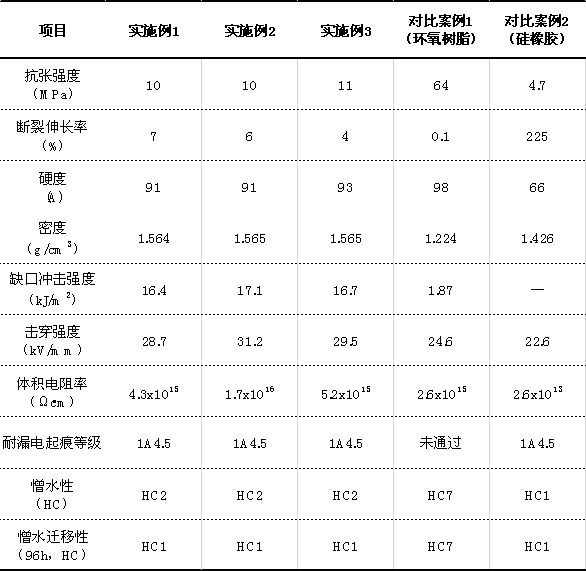

Examples

Embodiment 1

[0036] The invention provides a high-tough composite insulator shed material with hydrophobicity and hydrophobic mobility, including the following components and their quality: 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl ester (epoxy resin) 100g, hexahydrophthalic anhydride (curing agent) 90g, dimethylbenzylamine (accelerator) 0.5g, 2,4-diisocyanate (diisocyanate) 3g, siloxane coupling agent (coupling agent ) 4g, methyl silicone oil 20g, hydrogen-containing silicone oil 15g, aluminum hydroxide micropowder 120g, silicon micropowder 60g, silicone rubber powder 20g.

[0037] The preparation method is as follows:

[0038] (1) Take 100g of 4,5-epoxycyclohexane-1,2-dicarboxylic acid diglycidyl ester, then add 3g of 2,4-diisocyanate, use a heater to heat up to 50°C at 2000 rpm Stir at high speed, reduce the speed of the agitator to 600 rpm after the temperature rises to 70°C, and stir at a controlled temperature of 80°C for 1 hour;

[0039] (2) Continue to add 20g of meth...

Embodiment 2

[0047] The invention provides a high-tough composite insulator shed material with hydrophobicity and hydrophobic mobility, which includes the following components and their quality: 100g of tetraglycidyl diaminodiphenylmethane (epoxy resin), methyl inner Methyltetrahydrophthalic anhydride (curing agent) 100g, 2,4,6-tris(dimethylaminomethyl)phenol (accelerator) 0.7g, 2,4-diphenylmethane diisocyanate (diisocyanate ) 4g, hexamethyldisilazane (coupling agent) 4g, methyl silicone oil 30g, hydrogen-containing silicone oil 10g, aluminum hydroxide micropowder 140g, silicon micropowder 40g, silicone rubber powder 10g.

[0048] The preparation method is as follows:

[0049] (1) Take 100g of tetraglycidyl diaminodiphenylmethane, then add 4g of 2,4-diphenylmethane diisocyanate, use a heater to heat up to 50°C and stir at a high speed of 2500 rpm, and the temperature rises to 70 After ℃, reduce the speed of the stirrer to 800 rpm, and stir at a controlled temperature of 65 ℃ for 1.2 hours...

Embodiment 3

[0058] The invention provides a high-tough composite insulator shed material with hydrophobicity and hydrophobic mobility, which includes the following components and their quality: 100g of methyl 3,4-epoxycyclohexanecarboxylate (epoxy resin), Methyltetrahydrophthalic anhydride (curing agent) 87g, 2-methylimidazole (accelerator) 0.5g, triethanolamine (accelerator) 0.3g, 2,4-diisocyanate (diisocyanate) 3g, silicon oxide Alkane coupling agent (coupling agent) 3.5g, methyl silicone oil 30g, hydrogen-containing silicone oil 10g, aluminum hydroxide micropowder 100g, silicon micropowder 80g, silicone rubber powder 10g.

[0059] The preparation method is as follows:

[0060] (1) Add 3g of 2,4-diisocyanate to 100g of methyl 3,4-epoxycyclohexanecarboxylate, use a heater to heat up to 55°C and stir at a high speed of 2000 rpm, after the temperature rises to 65°C Reduce the speed of the stirrer to 600 rpm, and stir at a controlled temperature of 65°C for 1 hour;

[0061] (2) Continue t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com