Modified polyphenyl ether resin composition and high-frequency copper-clad plate prepared from same

A technology of polyphenylene ether resin and composition, which is applied in the directions of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of complex production process and the like, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

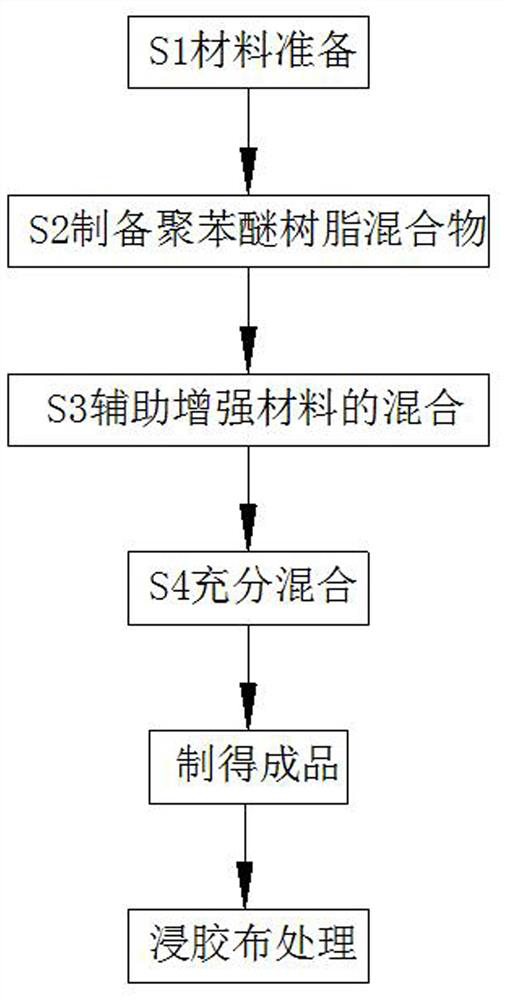

[0028] A modified polyphenylene ether resin composition, comprising the following preparation steps:

[0029] The first step: material preparation, prepare appropriate proportions of polyphenylene ether resin, thermoplastic resin, fibrous reinforcing materials, fillers, stabilizers, antioxidants, diluents, special copper foil and electronic grade glass cloth;

[0030] The second step: prepare the polyphenylene ether resin mixture, add an appropriate amount of polyphenylene ether resin and thermoplastic resin mixture into the mixer, mix for three minutes, then add the filler in proportion to the mixer, continue mixing for four minutes, After it is mixed evenly, add a proportional diluent to the mixture, the diluent is a mixture of amyl acetate, dioctyl phthalate, and methyl isobutyl ketone in the same proportion by mass, so that Stir evenly to make polyphenylene ether resin mixture;

[0031] The third step: mixing of auxiliary reinforcing materials, wherein the fibrous reinfor...

Embodiment 2

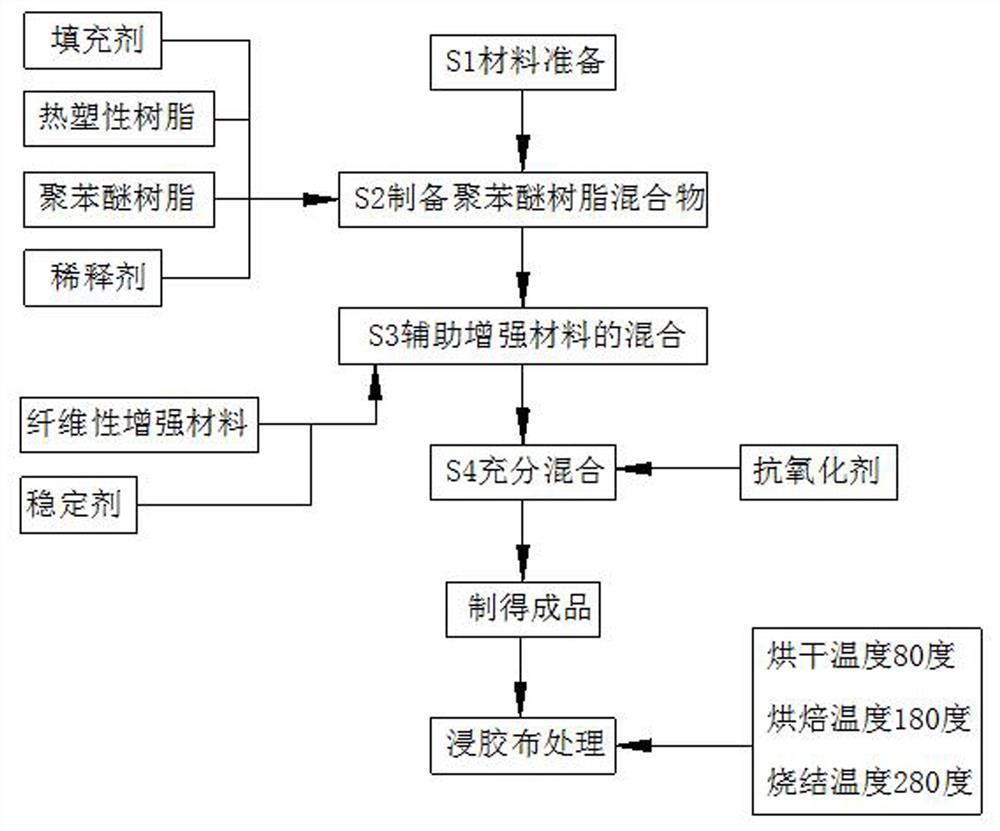

[0035] A modified polyphenylene ether resin composition, comprising the following preparation steps:

[0036] The first step: material preparation, prepare appropriate proportions of polyphenylene ether resin, thermoplastic resin, fibrous reinforcing materials, fillers, stabilizers, antioxidants, diluents, special copper foil and electronic grade glass cloth;

[0037] The second step: prepare polyphenylene ether resin mixture, add appropriate amount of polyphenylene ether resin and thermoplastic resin mixture into the mixer, mix for three minutes, then add appropriate amount of polyphenylene ether resin, polyhexamethylene adipamide and Thermoplastic resin, and mix for two minutes, then add the filler into the mixer in proportion, continue to mix for four minutes, after it is mixed evenly, add the diluent in proportion to the mixture, the diluent is amyl acetate and formazan base isobutyl ketone by the mixture of equal parts by mass, make it stir evenly, make polyphenylene ethe...

Embodiment 3

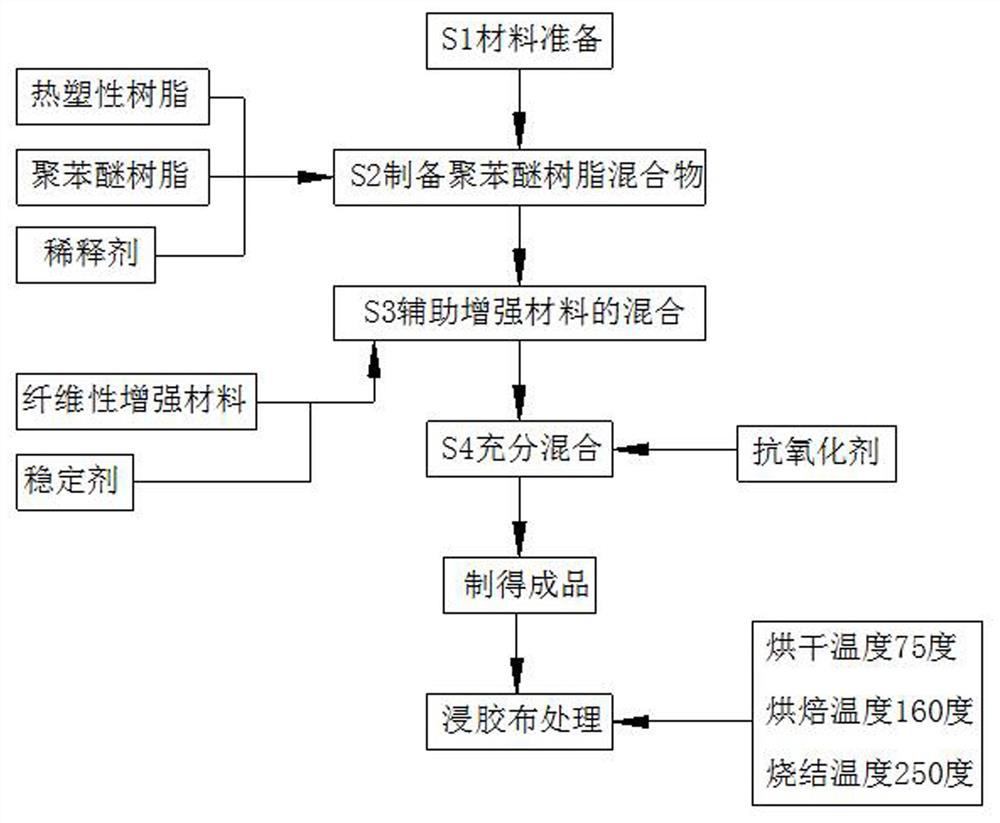

[0042] A modified polyphenylene ether resin composition, comprising the following preparation steps:

[0043] The first step: material preparation, prepare appropriate proportions of polyphenylene ether resin, thermoplastic resin, fibrous reinforcing material, stabilizer, special copper foil and electronic grade glass cloth;

[0044] The second step: prepare the polyphenylene ether resin mixture, add an appropriate amount of polyphenylene ether resin and thermoplastic resin mixture into the mixer, and mix for three minutes to prepare the polyphenylene ether resin mixture;

[0045] The third step: mixing of auxiliary reinforcing materials, wherein the fibrous reinforcing material and stabilizer are placed in the mixer in proportion, wherein the fibrous reinforcing material is made of glass fiber, silicon dioxide, and boron nitride in equal parts by mass. ratio of the mixture, mixed and stirred for ten minutes to make it uniform, and the auxiliary reinforcing material mixture was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com