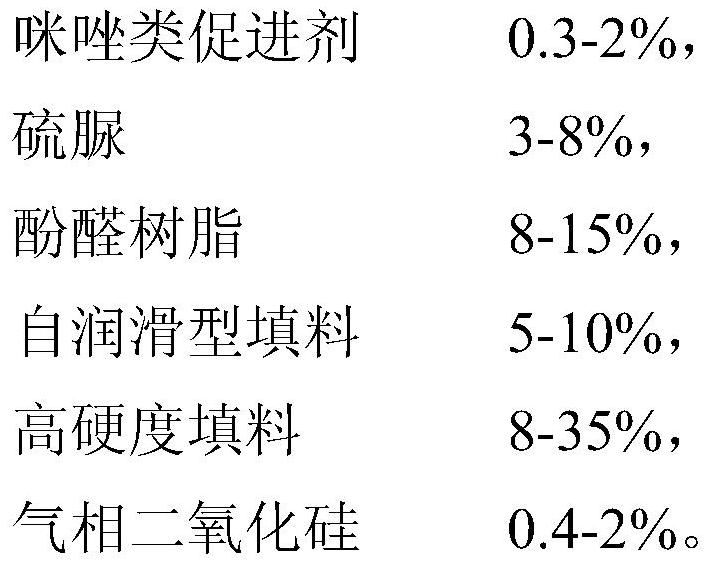

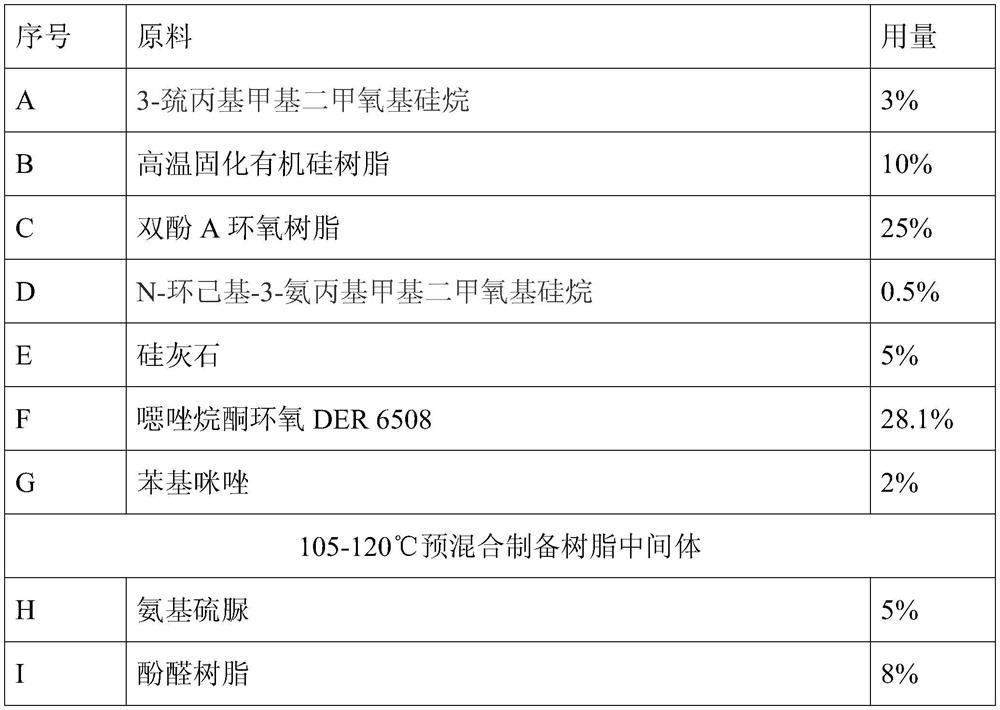

A kind of powder coating composition for blowout preventer and preparation method thereof

A technology of powder coatings and compositions, which is applied in the field of powder coating compositions for blowout preventers and its preparation, can solve the problems of unreported preparation methods, and achieve the effect of high temperature and autoclave resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

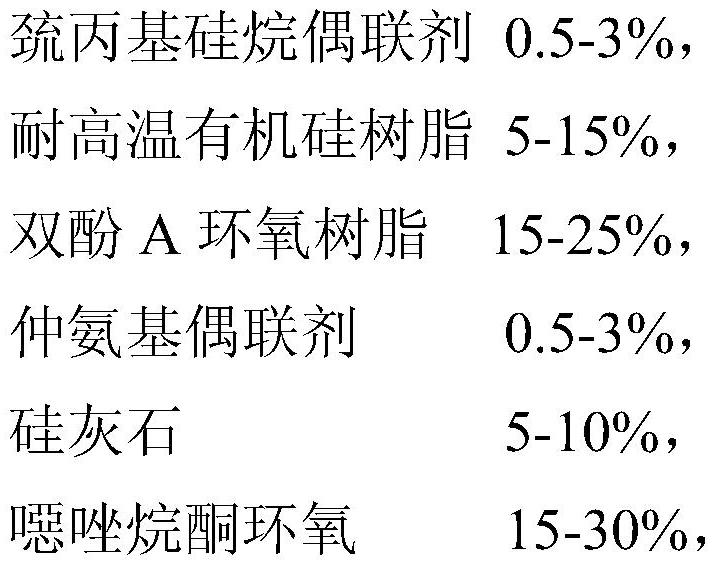

[0033] Table 1. Embodiment 1 powder coating formula

[0034]

[0035]

[0036] Preparation method: prepare raw materials according to the weight percentage in Table 1, melt and extrude A, B, C, D, E, F, G through a screw extruder at 105-120 ° C, and obtain an intermediate resin after tableting and crushing, and then the intermediate Bulk resin and H, I, J, K are mixed and melted at 120-130°C, melted and extruded, the tablet is crushed, and then L is added during the grinding process of the air mill (ACM mill) to obtain the powder coating.

[0037] The glass transition temperature TG2 of the prepared powder coating is 109°C, the gel time is 120S, the steel pipe is heated to 230°C, the powder coating is sprayed, and then cured for 90 minutes. The obtained coating can pass the test of the simulated working condition: 107°C / gas phase: 10Mpa (15% hydrogen sulfide, 6% carbon dioxide, 79% CH 4 ) / solvent phase: mixed solvent (toluene 50%, kerosene 50%) / water phase: 5% NaCl solu...

Embodiment 2

[0039] Table 2. Embodiment 2 powder coating formula

[0040]

[0041]

[0042] Preparation method: prepare raw materials according to the weight percentage in Table 2, melt and extrude A, B, C, D, E, F, G through a screw extruder at 105-120 ° C, and obtain an intermediate resin after pressing and crushing, and then the intermediate Bulk resin and H, I, J, K are mixed and melted at 120-130°C, melted and extruded, the tablet is crushed, and then L is added during the grinding process to obtain a powder coating.

[0043] The prepared powder coating TG2 is 115°C, the gel time is 100S, the steel pipe is heated to 230°C, the powder coating is sprayed, and then cured for 90 minutes. The obtained coating can pass the test of simulated working conditions: 107°C / gas phase: 10Mpa (15% hydrogen sulfide , 6% CO2, 79% CH 4 ) / solvent phase: mixed solvent (toluene 50%, kerosene 50%) / water phase: 5% NaCl solution, after 24 hours, the adhesion of the test piece reaches 5A level, and when...

Embodiment 3

[0045] Table 3. Embodiment 3 powder coating formula

[0046]

[0047]

[0048] Preparation method: prepare raw materials according to the weight percentage in Table 3, melt and extrude A, B, C, D, E, F, G through a screw extruder at 105-120 ° C, and obtain intermediate resin after tableting and crushing, and then intermediate Bulk resin and H, I, J, K are mixed and melted at 120-130°C, melted and extruded, the tablet is crushed, and then L is added during the grinding process to obtain a powder coating.

[0049] The prepared powder coating TG2 is 115°C, gel time is 80S, the steel pipe is heated to 230°C, the powder coating is sprayed, and then cured for 90min, the obtained coating can pass the test of simulated working conditions: 107°C / gas phase: 10Mpa (15% hydrogen sulfide , 6% CO2, 79% CH 4 ) / solvent phase: mixed solvent (toluene 50%, kerosene 50%) / water phase: 5% NaCl solution, after 24h the adhesion of the test piece reaches 5A level; Sand for 30 minutes without rev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com