Te-doped Cs2ZrCl6 perovskite derivative material and preparation method and application thereof

A derivative and perovskite technology, applied in the field of photoluminescence fluorescence of perovskite derivatives, can solve the problem that lead-free halide perovskite cannot match the photoelectric performance of lead-based perovskite, and achieve low cost, Wide application prospects, easy to obtain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

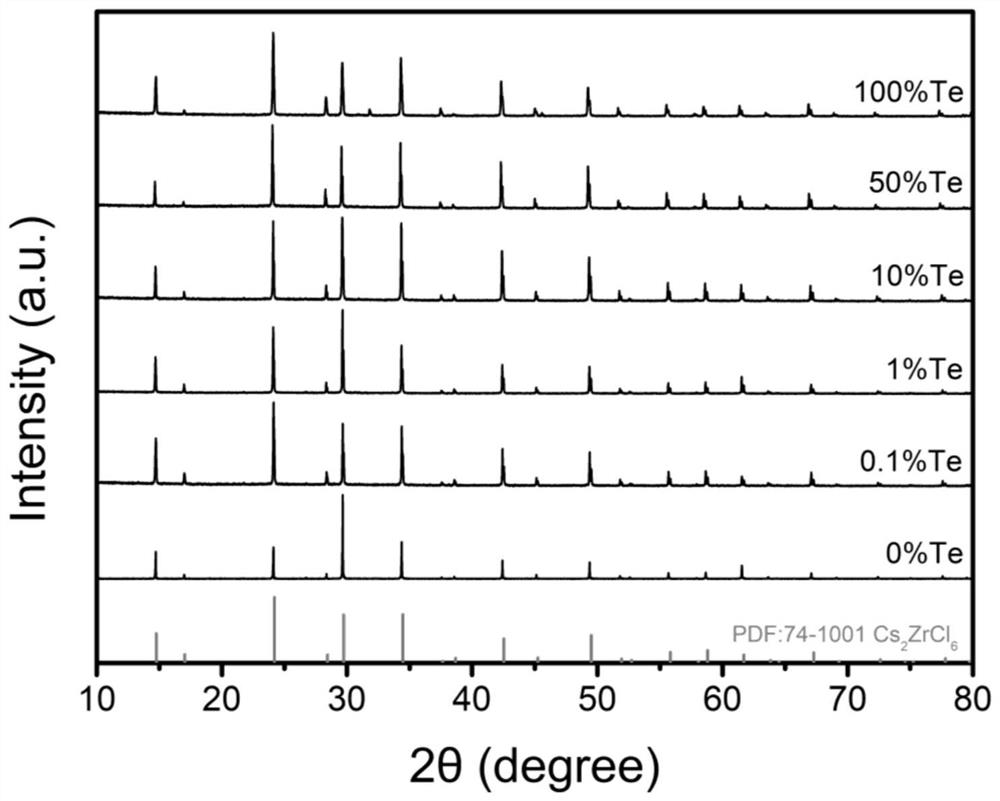

Method used

Image

Examples

Embodiment 1

[0030] (1) Place 1 mmol of cesium chloride and 0.5 mmol of zirconium chloride in a Teflon liner, and add 5 mL of concentrated hydrochloric acid.

[0031] (2) Put the Teflon lining in the reaction kettle, move it to an oven and keep it at 180°C for 4 hours, and then slowly cool it down to room temperature.

[0032] (3) The reactant was washed with ethanol for 3 times, placed in an oven, heated at 70° C. for 4 hours, and dried to obtain a solid powder.

Embodiment 2

[0034] (1) Place 1 mmol of cesium chloride, 0.5 mmol of zirconium chloride and 0.0005 mmol of tellurium tetrachloride in a Teflon liner, and add 5 mL of concentrated hydrochloric acid.

[0035] (2) Put the Teflon lining in the reaction kettle, move it to an oven and keep it at 180°C for 4 hours, and then slowly cool it down to room temperature.

[0036] (3) The reactant was washed with ethanol for 3 times, placed in an oven, heated at 70° C. for 4 hours, and dried to obtain a solid powder.

Embodiment 3

[0038] (1) Place 1 mmol of cesium chloride, 0.5 mmol of zirconium chloride and 0.005 mmol of tellurium tetrachloride in a Teflon liner, and add 5 mL of concentrated hydrochloric acid.

[0039] (2) Put the Teflon lining in the reaction kettle, move it to an oven and keep it at 180°C for 4 hours, and then slowly cool it down to room temperature.

[0040] (3) The reactant was washed with ethanol for 3 times, placed in an oven, heated at 70° C. for 4 hours, and dried to obtain a solid powder.

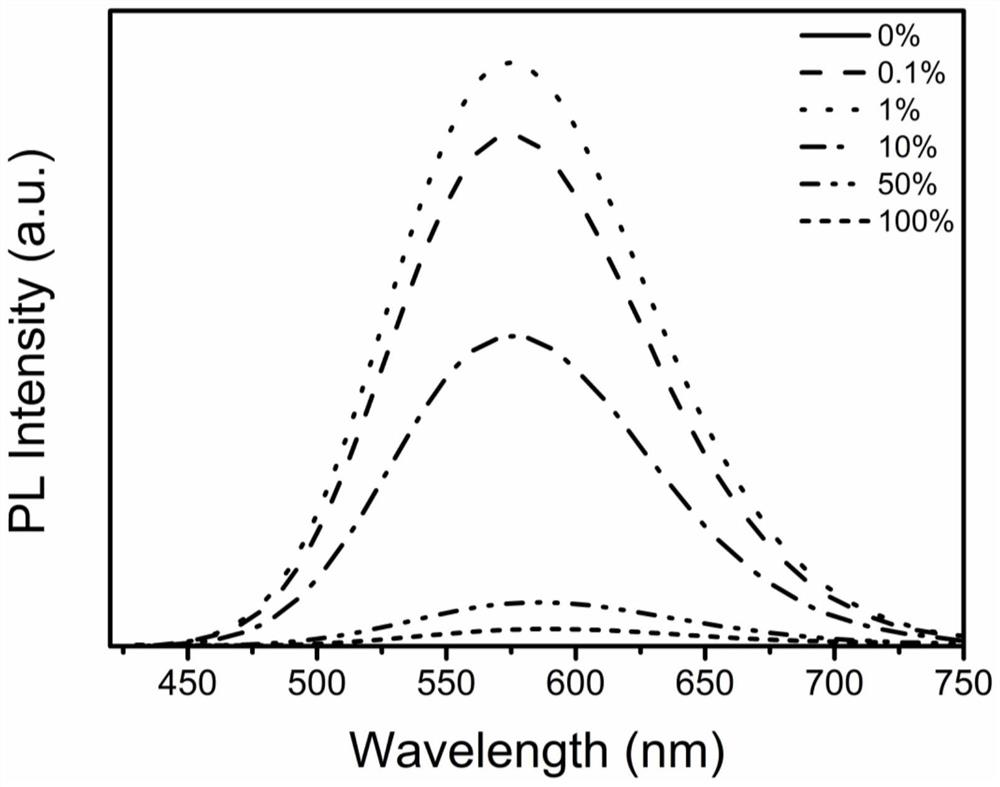

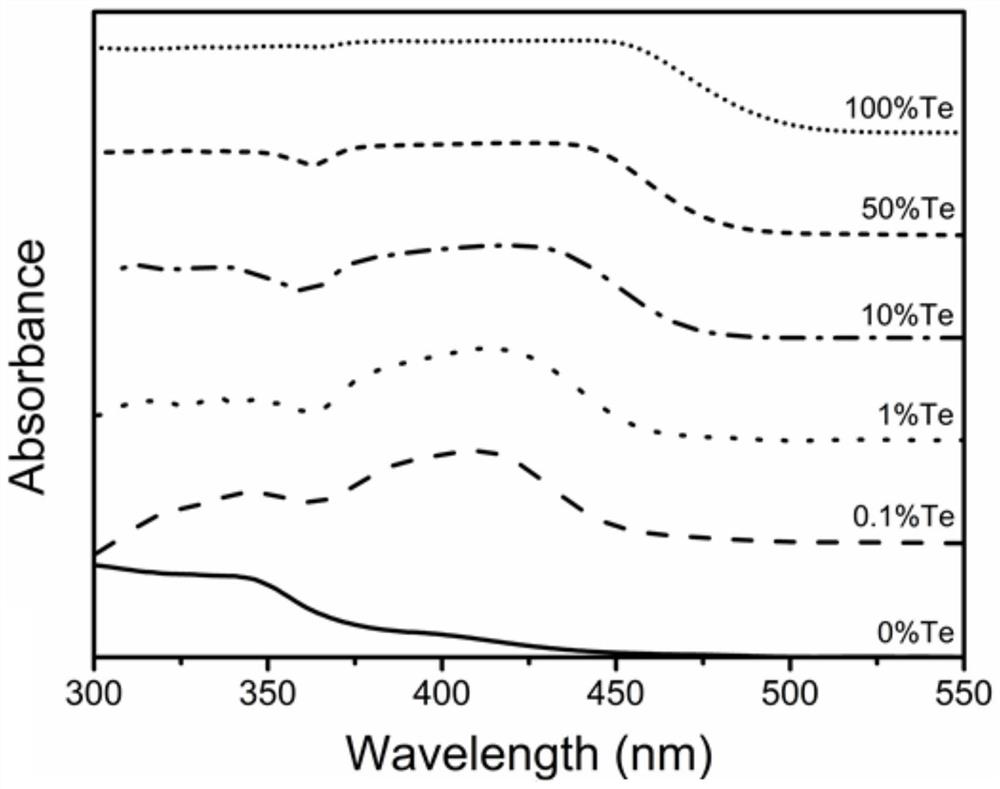

[0041] Te doped Cs prepared in this embodiment 2 ZrCl 6 The perovskite derivative powder is fully mixed with the epoxy resin, and then the obtained slurry is coated on the surface of the light-emitting diode chip (395nm), and finally cured at 50-150°C for 0.5-72h to make the light-emitting diode device. like Figure 4 As shown, Te-doped Cs 2 ZrCl 6 The color coordinate (CIE) diagram of the perovskite derivative light-emitting diode, the coordinate value is (0.466,0.506), the main wavelen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com