Circulating drying device for lithium battery raw material processing

A drying device and lithium battery technology, applied in heating devices, drying, dryers and other directions, can solve the problems of turning into liquid, water droplets are difficult to evaporate quickly, and cannot be collected and utilized, so as to improve the feeding speed. , the effect of improving efficiency and increasing the amount of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

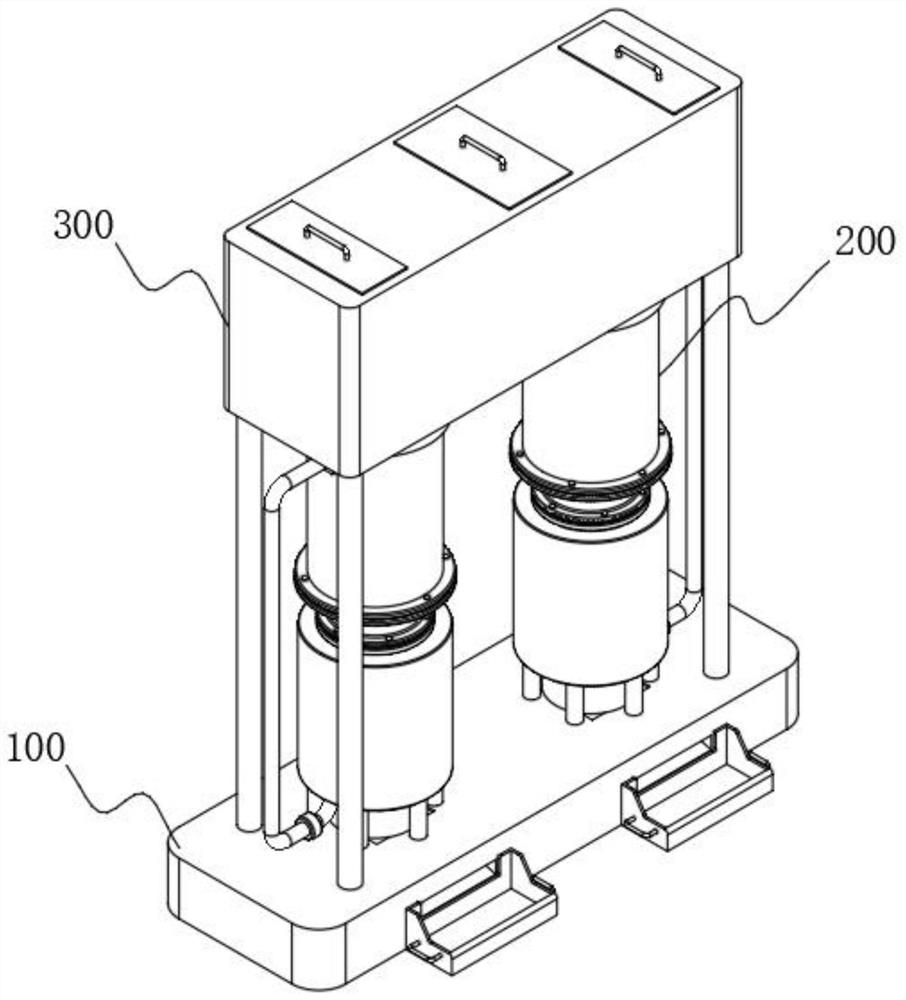

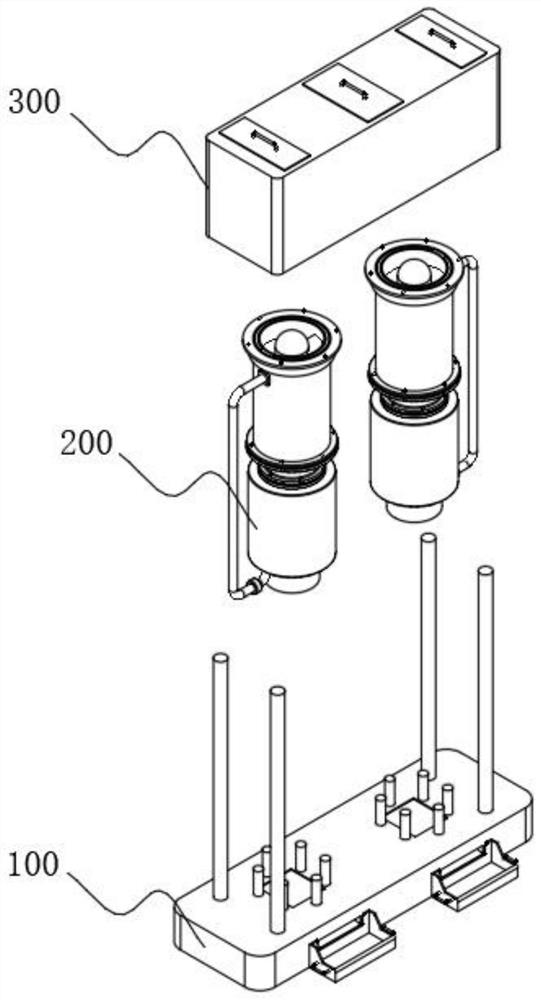

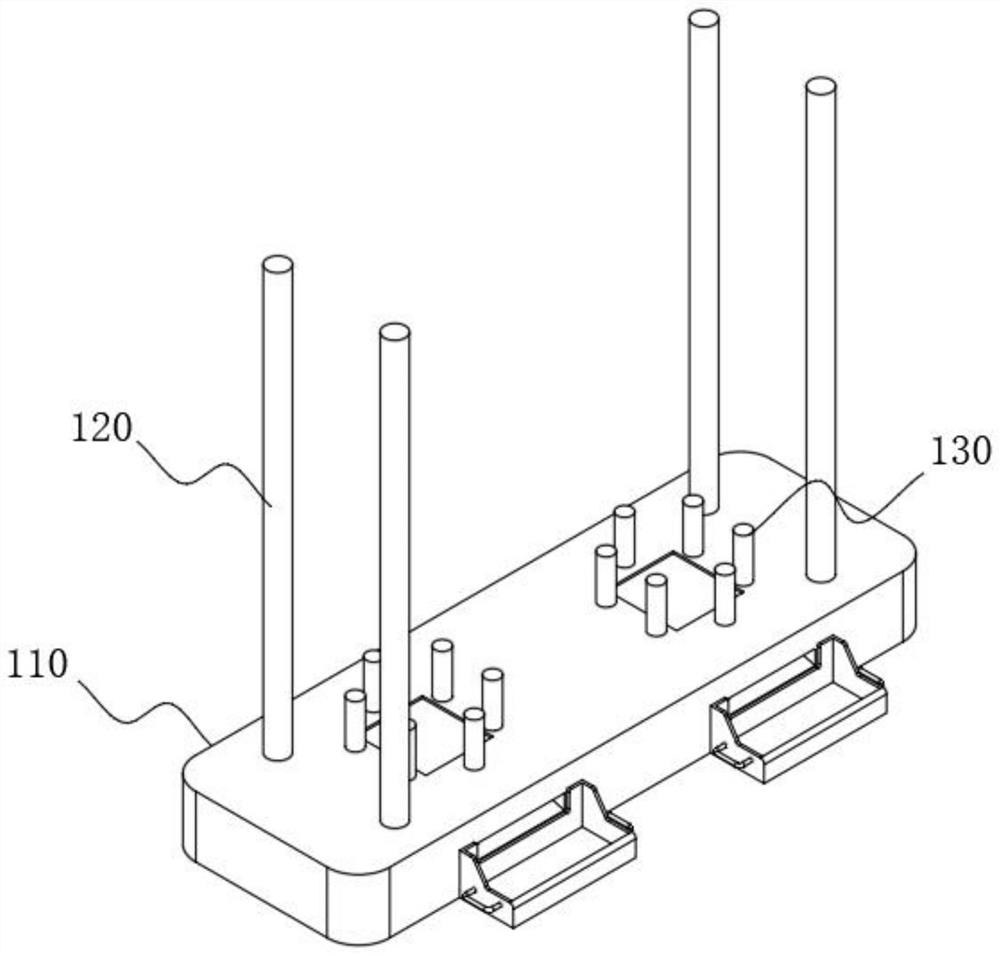

[0063] see Figure 1-Figure 13 As shown, the purpose of this embodiment is to provide a circulation drying device for lithium battery raw material processing, including a support mechanism 100, two circulation drying mechanisms 200 arranged on the top of the support mechanism 100, and a circulation drying mechanism arranged on the top of the circulation drying mechanism 200 The feeding mechanism 300 at the top, the support mechanism 100 includes a base 110, the base 110 is arranged on the bottom of the circulation drying mechanism 200, the circulation drying mechanism 200 includes a heating and drying device 210, and the heating and drying device 210 includes a heating barrel 211, and the heating barrel The inside of 211 is provided with a heating cavity, and a heating plate 212 is arranged in the heating cavity. An electric heating device for cavity heating. The electric heating device preferably adopts an electromagnetic heating coil. Its working principle is as well known t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com