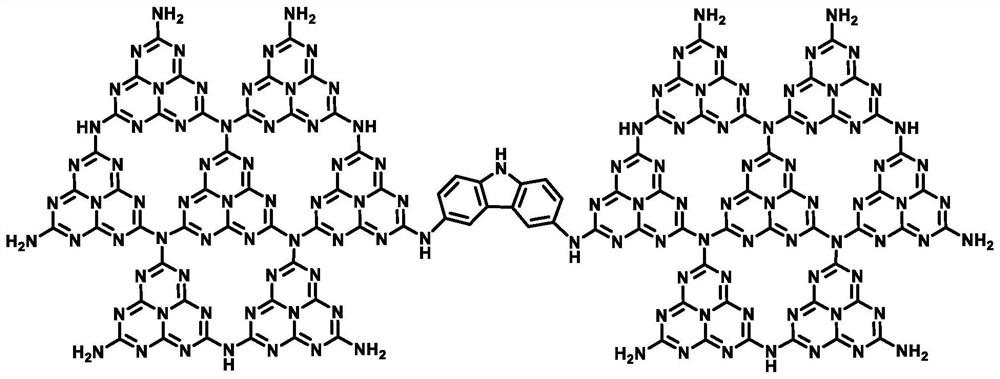

Two-dimensional carbon nitride photocatalyst containing D-A structure as well as preparation method and application thereof

A D-A, catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high electron-hole pair recombination rate, insufficient visible light absorption, and high exciton binding energy, Achieve the effect of many active sites, efficient photocatalytic reduction of CO2 activity, and wide light response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

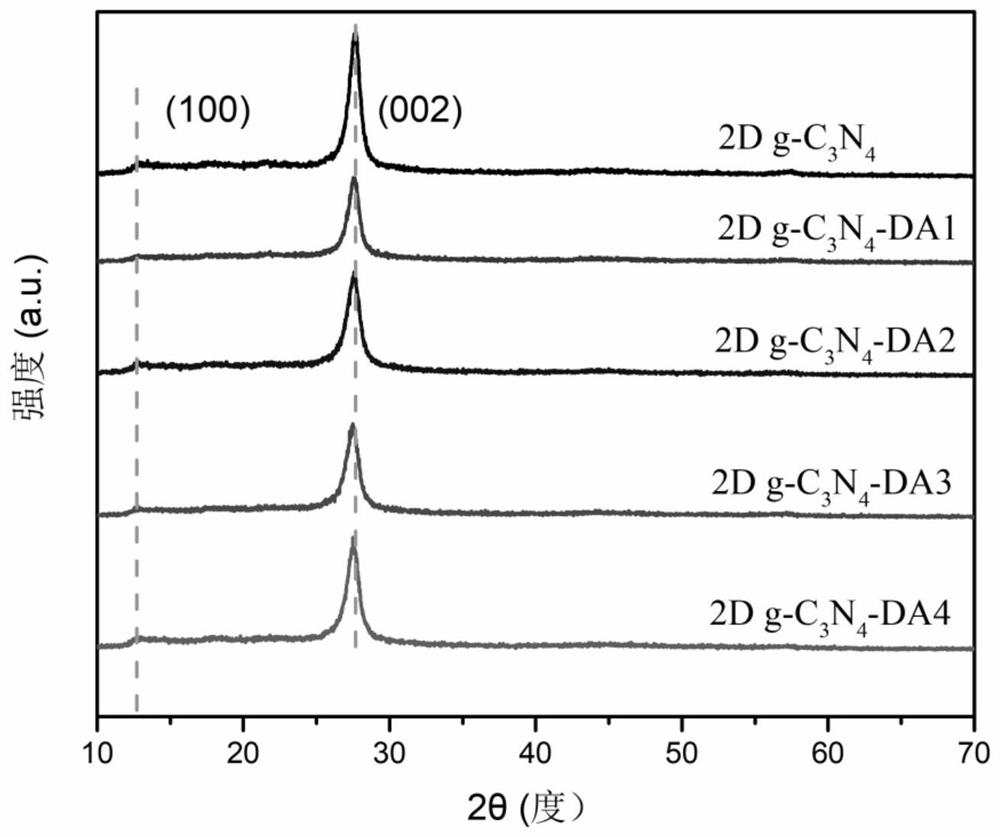

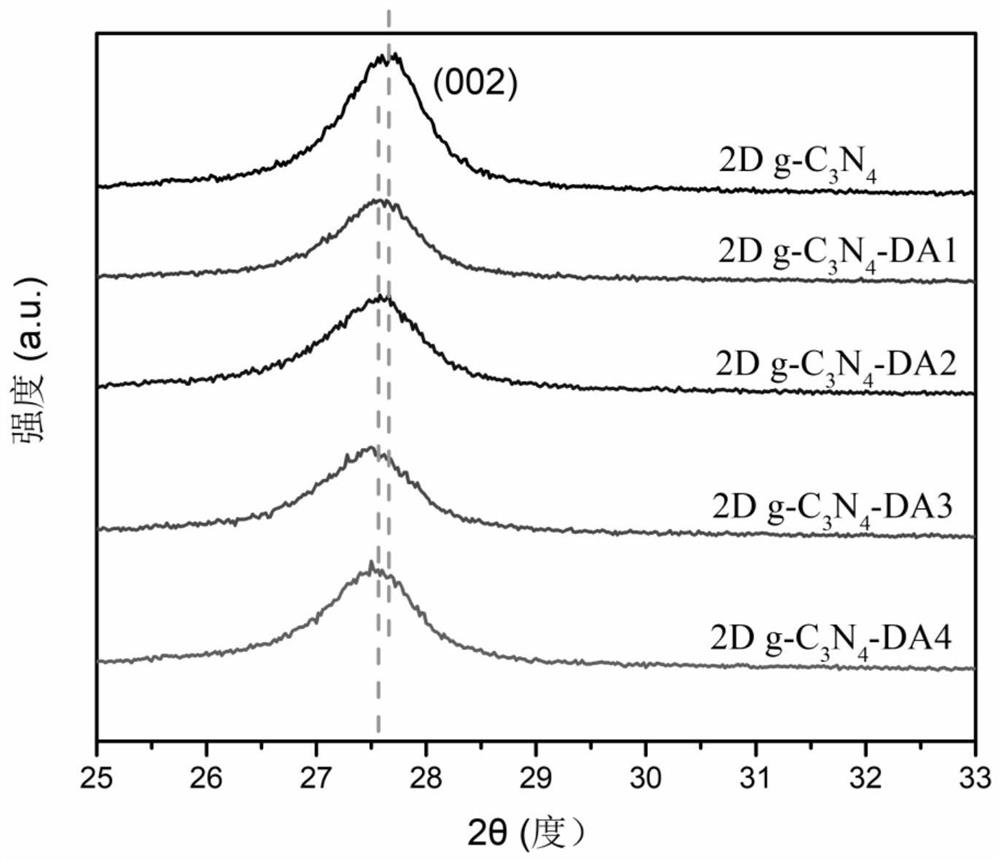

Embodiment 1

[0031] (1) Bulk phase g-C 3 N 4 Preparation of:

[0032] Put 3 g of melamine in a 2×4 cm porcelain boat, and seal it with tin foil. Then in the muffle furnace, the temperature was raised to 550°C at a rate of 2°C / min, roasted for 4 hours, cooled naturally, and the obtained yellow blocky solid was ground into powder;

[0033] (2)2D g-C 3 N 4 Preparation of nanosheets:

[0034] bulk phase g-C 3 N 4 The powder was added to a 2×4cm porcelain boat and sealed with tin foil. Use a 1mm diameter needle to make a row of small holes (5 pcs) in the middle of the foil. Then in the muffle furnace, the temperature was raised to 550 °C at a rate of 5 °C / min, and it was calcined at this temperature for 4 h, and cooled naturally to obtain 2D g-C 3 N 4 Nanosheets.

[0035] (3) 2D g-C 3 N 4 - Preparation of DA

[0036] Disperse 0.005g, 0.01g, 0.03g, 0.05g of 3,6-dibromocarbazole into 10mL of acetone, ultrasonic power 1000W, ultrasonic time 0.5h, ultrasonic to obtain solution 1. The...

Embodiment 2

[0039] (1) Bulk phase g-C 3 N 4 Preparation of:

[0040] Put 3 g of melamine in a 2×4 cm porcelain boat, and seal it with tin foil. Then in the muffle furnace, the temperature was raised to 550°C at a rate of 2°C / min, roasted for 4 hours, cooled naturally, and the obtained yellow blocky solid was ground into powder;

[0041] (2)2D g-C 3 N 4 Preparation of nanosheets:

[0042] bulk phase g-C 3 N 4 The powder was added to a 2×4cm porcelain boat and sealed with tin foil. Use a 1mm diameter needle to make a row of small holes (5 pcs) in the middle of the foil. Then in the muffle furnace, the temperature was raised to 550 °C at a rate of 5 °C / min, and it was calcined at this temperature for 4 h, and cooled naturally to obtain 2D g-C 3 N 4 Nanosheets.

[0043] (3) 2D g-C 3 N 4 - Preparation of DAb

[0044] Disperse 0.01g of 1,4-dibromobenzene into 10mL of acetone, ultrasonic power 1000W, ultrasonic time 0.5h, ultrasonic to obtain solution 1. Then 0.2g 2D g-C 3 N 4 T...

Embodiment 3

[0047] (1) Bulk phase g-C 3 N 4 Preparation of:

[0048] Put 3 g of melamine in a 2×4 cm porcelain boat, and seal it with tin foil. Then in the muffle furnace, the temperature was raised to 550°C at a rate of 2°C / min, roasted for 4 hours, cooled naturally, and the obtained yellow blocky solid was ground into powder;

[0049] (2)2D g-C 3 N 4 Preparation of nanosheets:

[0050] bulk phase g-C 3 N 4 The powder was added to a 2×4cm porcelain boat and sealed with tin foil. Use a 1mm diameter needle to make a row of small holes (5 pcs) in the middle of the foil. Then in the muffle furnace, the temperature was raised to 550 °C at a rate of 5 °C / min, and it was calcined at this temperature for 4 h, and cooled naturally to obtain 2D g-C 3 N 4 Nanosheets.

[0051] (3) 2D g-C 3 N 4 - Preparation of DAdbt

[0052] Disperse 0.01g of 4,7-dibromo-2,1,3-benzothiadiazole into 10mL of methanol, ultrasonic power 1000W, ultrasonic time 0.5h, ultrasonic to obtain solution 1. Then 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com