Novel process for producing baking soda

A production process and technology of baking soda, applied in the directions of alkali metal compounds, inorganic chemistry, alkali metal carbonates, etc., can solve the problems of high cost of soda ash carbonization and composite method, low cost of trona method, cumbersome technological process, etc. To achieve the effect of reducing production costs, less equipment investment, and reducing process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

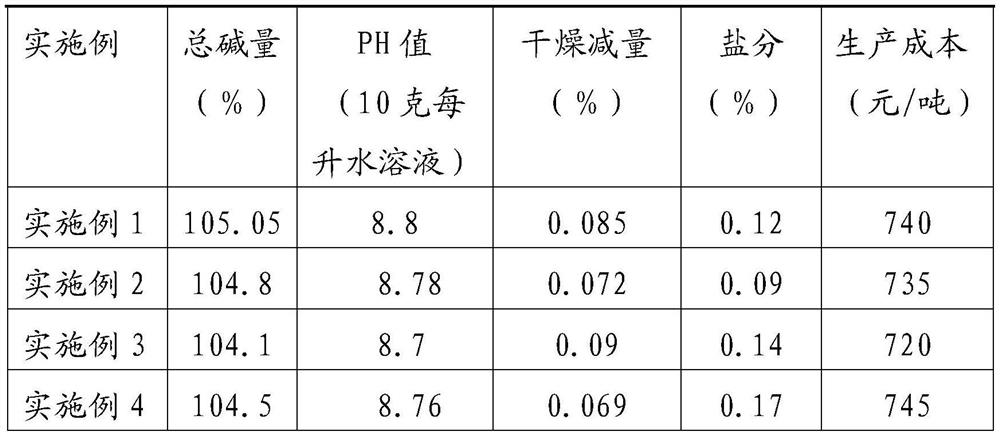

Embodiment 1

[0029] A new process for producing baking soda. The centrifuged wet heavy alkali (moisture content 8%) and heated air are respectively sent to a rotatable production device. The feed temperature of the wet heavy alkali is 20°C, and the air feed The gas temperature is 180°C, the internal pressure of the production device is 0.09MPa, the rotation speed of the production device is 10r / min, the wet heavy alkali and the air gas are contacted and reacted inside the production device, and the gas outlet temperature of the production device is 75°C. The discharge temperature of the baking soda product is 65°C. The time to produce every ton of sodium bicarbonate product under this process condition by finished product analysis is 3min.

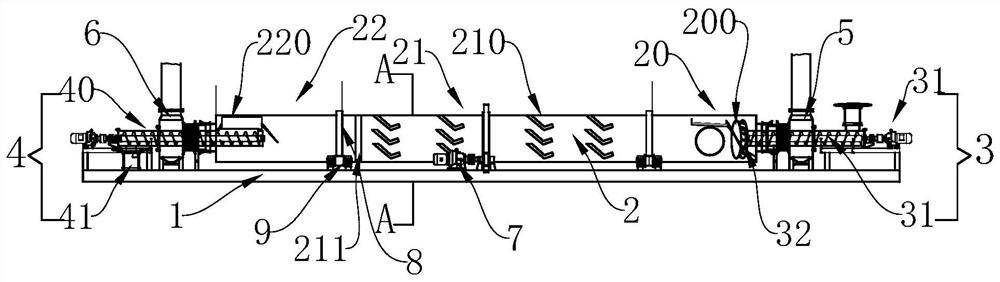

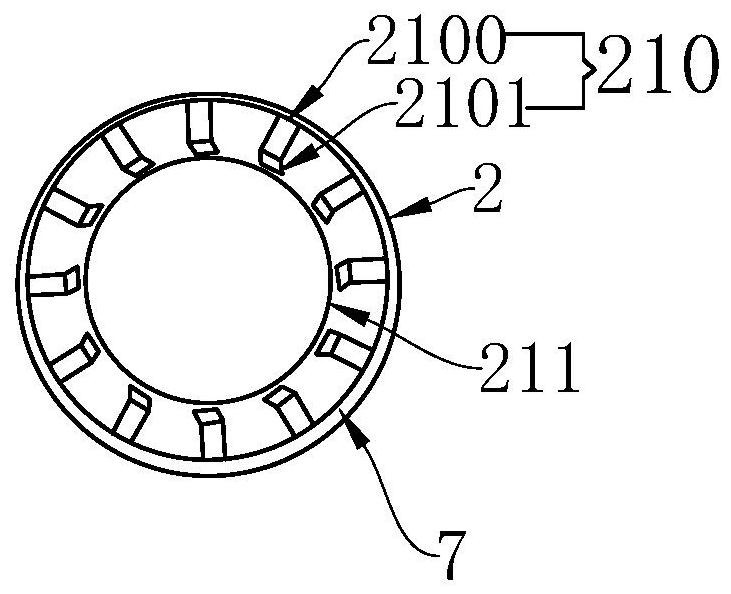

[0030] The production setup consists of rack 1, such as figure 1As shown, the frame 1 is provided with a rotatable reactor 2, one end of the reactor 2 is provided with a feed mechanism 3, the other end of the reactor 2 is provided with a discharge mec...

Embodiment 2

[0038] A new process for producing baking soda. The centrifuged wet heavy alkali (8.5% total moisture content) and the heated air are respectively sent to a rotatable production device. The feed temperature of the wet heavy alkali is 25°C, and the air The temperature is 170°C, the internal pressure of the production device is 0.06MPa, the speed of the production device is 9r / min, the wet heavy alkali and the air contact and react in the forward direction inside the production device, the gas outlet temperature in the production device is 70°C, and the baking soda The discharge temperature of the product is 65°C. The time to produce every ton of sodium bicarbonate product under this technological condition is 3.2min through finished product analysis.

Embodiment 3

[0040] A new process for producing baking soda. The centrifuged wet heavy alkali (water content 9%) and heated air are respectively sent to a rotatable production device. The feed temperature of the wet heavy alkali is 28°C, and the carbon dioxide feed is The temperature of the gas is 160°C (the carbon dioxide gas fills the inside of the reactor of the production device during the whole reaction process), the internal pressure of the production device is 0.04MPa, the speed of the production device is 8r / min, and the wet heavy alkali and carbon dioxide gas flow smoothly in the production device. To the contact reaction, the outlet temperature of the gas in the production device is 65°C, and the outlet temperature of the baking soda product is 62°C. The time to produce every ton of sodium bicarbonate product under this technological condition is 4min through finished product analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com