Engineering bacteria for producing maleic acid, and construction method and applications thereof

A technology of engineering bacteria and maleic acid, applied in the field of bioengineering, can solve problems such as environmental pollution and non-renewable energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Recombinant plasmid pZE-NagAaGHAb, pCS-EP-Mps-Hbzf

[0040] The recombinant plasmid pZE-NagAaGHAb provided in this example is mainly obtained by linking the gene NagAaGHAb to the Escherichia coli expression vector pZE12-luc. pCS-EP-Mps-Hbzf is mainly obtained by linking genes EntC, PchB, Mps, Hbzf to E. coli expression vector pCS27.

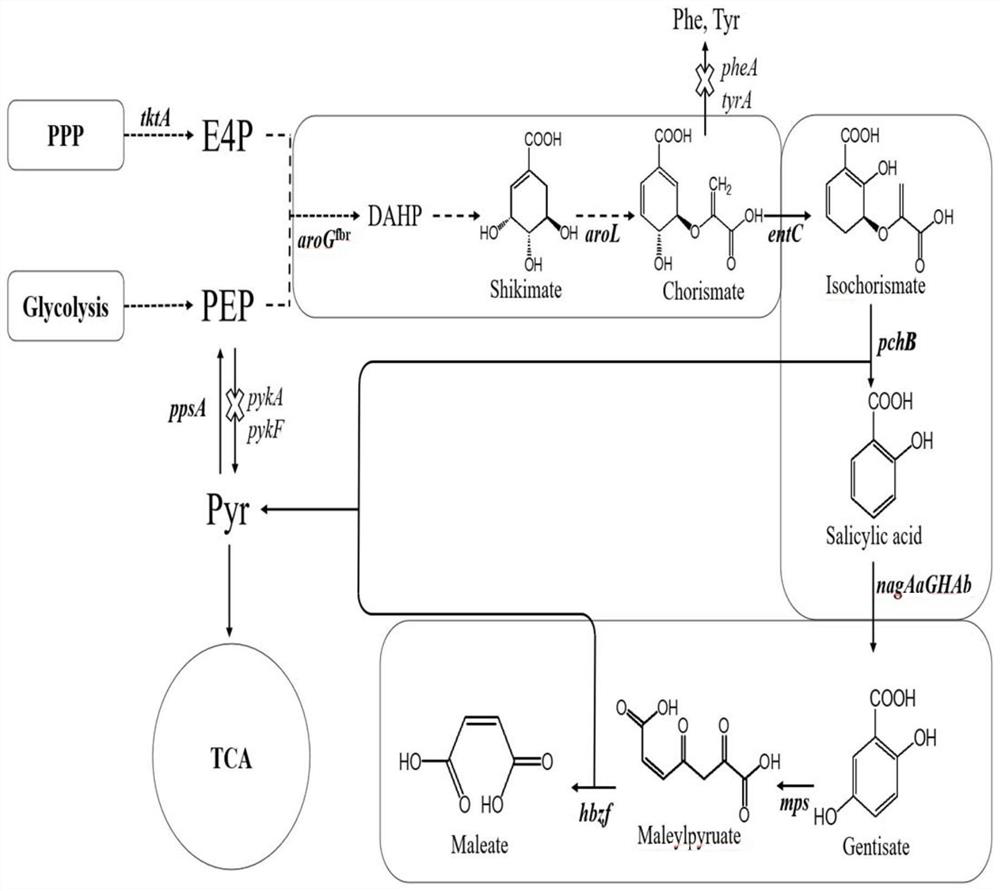

[0041] The method for constructing the above-mentioned recombinant plasmid provided in this example specifically includes the following steps. Screening of genes encoding isochorisate synthase (EntC), isochorisate pyruvate lyase (PchB), salicylate-5-hydroxylase (NagAaGHAb), maleylpyruvate from bacteria, fungi or protein engineering Genes for isomerase (Mps) and maleylpyruvate lyase (Hbzf). By combining isochoristate synthase (EntC), isochoristate pyruvate lyase (PchB), salicylate-5-hydroxylase (NagAaGHAb), maleylpyruvate isomerase (Mps) and After the target gene of acetylpyruvate lyase (Hbzf) is amplified by PCR to obtain the target fra...

Embodiment 2

[0043] Engineering bacteria producing maleic acid: Recombinant Escherichia coli BW1

[0044] The maleic acid-producing engineering bacteria provided by the present invention have no special requirements on the type of host strain used to construct the expression plasmid. The embodiment of the present invention uses the BW25113 (F') strain as the initial host for constructing the plasmid.

[0045] First pick fresh BW25113(F’) colonies and inoculate them into 4mL LB medium, incubate at 37°C for 8-12h, then inoculate 1mL into 100mL LB medium, and incubate at 37°C until OD 600 When the growth reaches 0.6, centrifuge at 6000rpm at 4°C for 10min to collect the bacteria, wash with 10mL of 10% glycerin solution (mass ratio, the same below) pre-cooled to 4°C, centrifuge at 6000rpm for 10min, repeat the glycerin washing step, and centrifuge Finally, pour off the remaining glycerol as much as possible, and finally add 300 μL of 10% glycerol solution to resuspend the cells to obtain compe...

Embodiment 3

[0047] Application of Recombinant Escherichia coli BW1: Production of Maleic Acid by Fermentative Culture

[0048] Pick fresh recombinant Escherichia coli BW1 engineered single colonies on the plate and inoculate them into 4 mL LB test tubes containing ampicillin and kana. After culturing at 37°C for 8 hours, transfer them to shake flasks containing 50 mL medium containing ampicillin and kana for fermentation For cultivation, the inoculum size is 2% by volume, the fermentation temperature is 30° C. or 37° C., and the rotation speed is 200 rpm. Wherein, the medium: 2g·L -1 MOPS, 20g·L -1 Glucose, 10g·L -1 Glycerin, 5g·L -1 Yeast powder, 6g·L -1 NaHPO 4 , 0.5g·L -1 NaCl, 3g·L -1 K H 2 PO 4 , 2g·L -1 NH 4 Cl, 246.5mg L -1 MgSO 4 , 14.7mg·L -1 CaCl 2 , and add ampicillin and kanamycin.

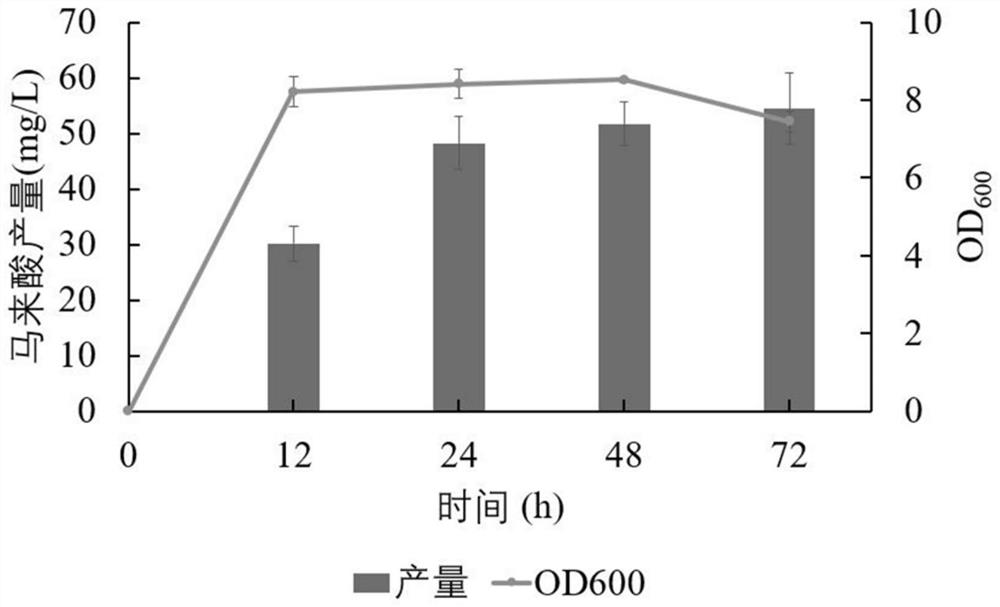

[0049] The induction agent IPTG with a final concentration of 0.5mM was initially added to the fermentation, and part of the fermentation broth was taken out every 12 hours to mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com