Bacteriostatic, anti-scaling and high-temperature-resistant aluminum-plastic composite pipe

An aluminum-plastic composite pipe, high-temperature-resistant technology, applied to pipes, rigid pipes, tubular objects, etc., can solve problems such as poor heat resistance, easy delamination at the hot-melt adhesive bonding of pipes, and failure to apply heat sink pipes, etc. , to achieve the effect of reducing roughness, delaying fouling time, and improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

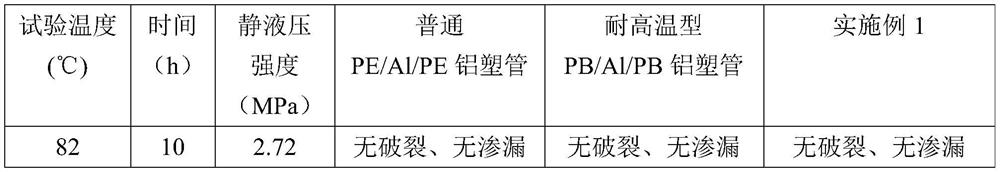

Embodiment 1

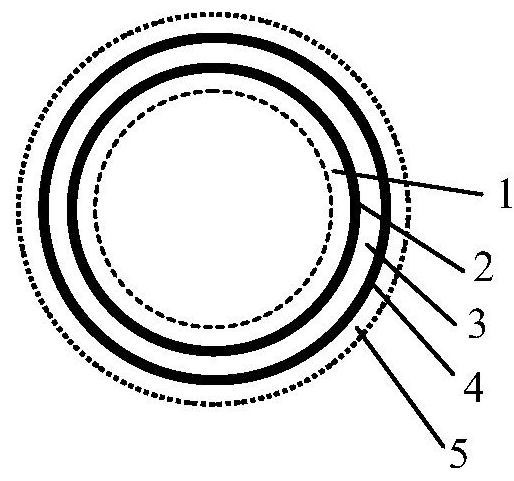

[0035] An antibacterial, anti-scaling, and high-temperature-resistant aluminum-plastic composite pipe. The inner layer of the pipe is a modified PB material added with antibacterial masterbatch and anti-scaling masterbatch. The third layer is an aluminum alloy layer, and the outermost layer is PB resin. The inner and outer layers of the pipe are bonded to the third layer by high temperature resistant hot melt adhesive. in:

[0036] The first layer 1 of the pipe is the inner layer of the pipe, which is a modified PB resin added with antibacterial masterbatch and anti-fouling masterbatch, accounting for 58% of the entire wall thickness. Among them, the antibacterial masterbatch is obtained by mixing and granulating nano-copper powder with a particle size of 200nm and PB resin; the anti-fouling masterbatch is obtained by mixing and granulating silicone powder and PB resin. Among them, the silicone powder is a homogeneous mixture obtained under strong shear conditions of 40% silo...

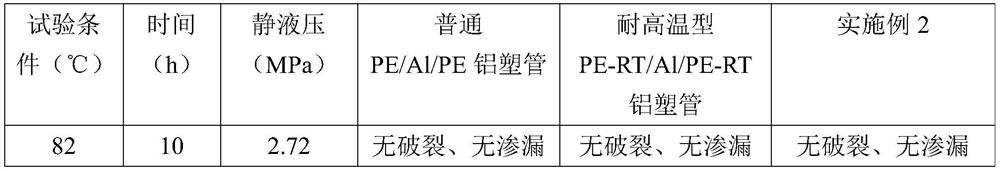

Embodiment 2

[0048] An antibacterial, anti-scaling, and high-temperature-resistant aluminum-plastic composite pipe. The inner layer of the pipe is a modified type II PE-RT pipe added with antibacterial masterbatch and anti-scaling masterbatch. The third layer is an aluminum alloy layer, and the outermost layer is It is type II PE-RT base material, and the inner and outer layers of the pipe are bonded with the third layer by high temperature resistant hot melt adhesive. in:

[0049] The inner layer of the pipe is a modified type II PE-RT resin added with antibacterial masterbatch and anti-fouling masterbatch, accounting for 58% of the entire wall thickness. Among them, the antibacterial masterbatch is obtained by mixing and granulating nano-silver ion antibacterial agent with type II PE-RT resin; The resin is obtained by mixing and granulating. Then the antibacterial masterbatch, anti-fouling masterbatch and PE-RT resin base material are blended, the nano silver ion antibacterial agent ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com