Wafer anti-sticking device

An anti-sticking, wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as shadow effect, clamp ring wafer sticking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

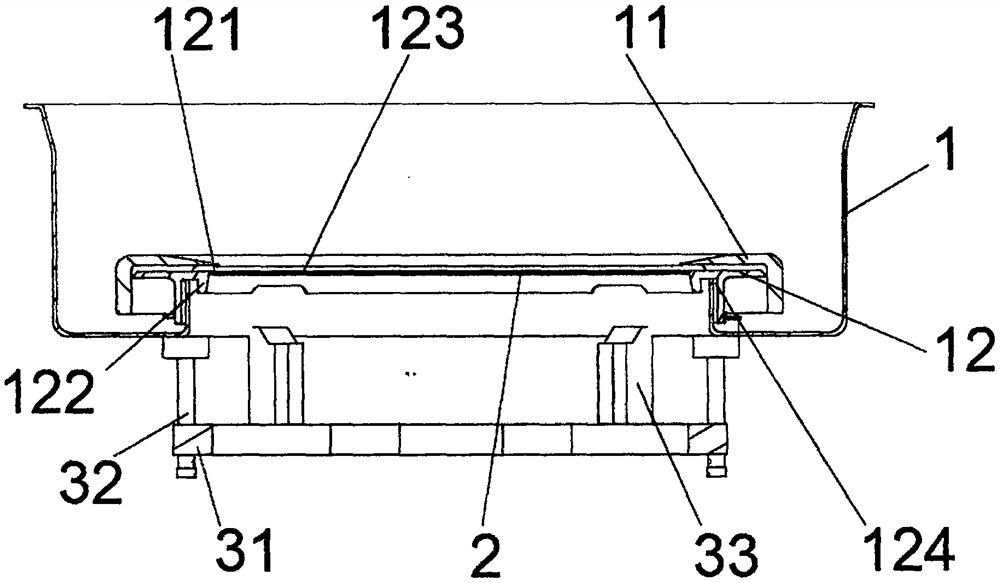

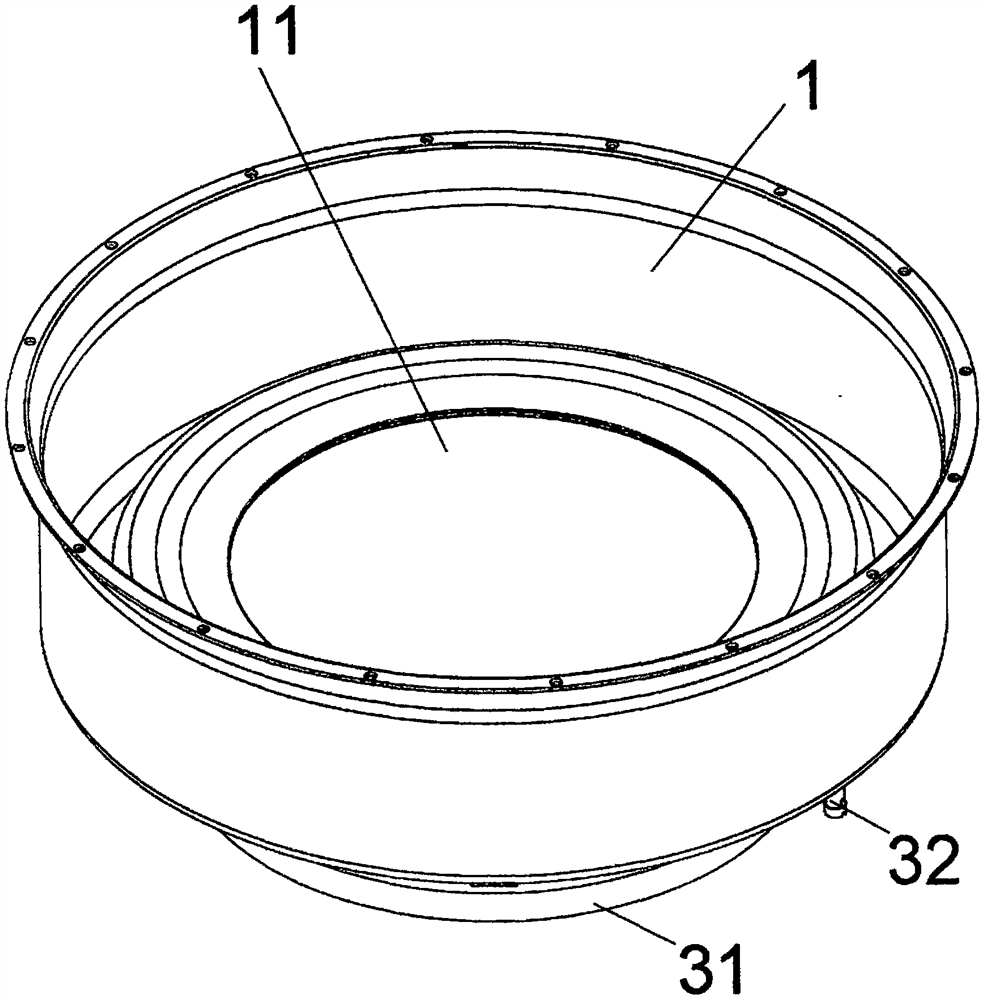

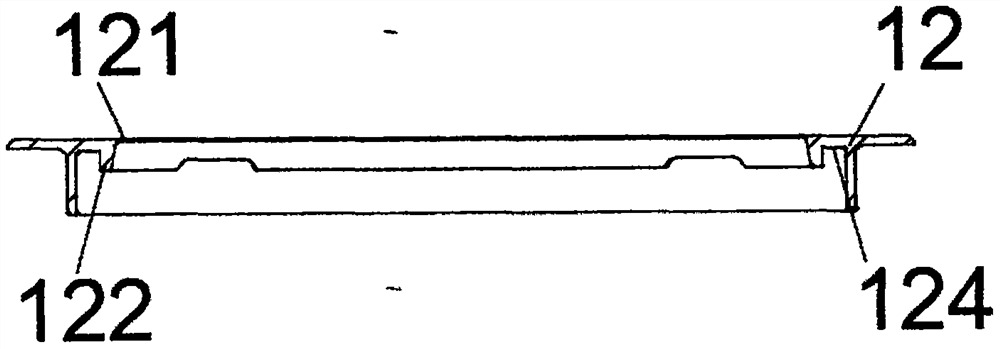

[0017] see Figure 1-4 As shown, the present invention provides a technical solution for a wafer anti-sticking device: it includes a protective cover 1, the bottom wall of the protective cover 1 is arranged in a through shape, the bottom of the protective cover 1 is provided with a lifting assembly, and a top shield is provided above the lifting assembly. Plate 11, specifically, the top shielding plate 11 is used to provide a shielding function for the lower clamping ring, and to prevent deposition at the wafer clamping contact point 121 between the lower edge clamping ring 122 and the edge of the wafer 2 during the deposition process, the top The shielding plate 11 is adapted to the bottom of the protective cover 1, and the top inner wall of the top shielding plate 11 is provided with a lower clamping ring 12, and the upper inner wall of the lower clamping ring 12 is provided with a wafer clamping contact point 121, and the wafer clamping contacts The point 121 is used to cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com