Multi-layer microstrip board processing method based on perovskite ceramic filling substrate

A processing method and perovskite technology are applied in multilayer circuit manufacturing, circuit metal processing, and electrical connection formation of printed components, etc., which can solve the problems of difficult deposition of copper layers, poor adhesion and easy falling off, poor hydrophilicity, etc., and achieve High surface activity, less microscopic defects, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

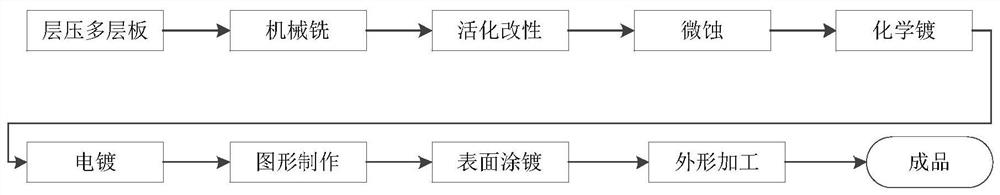

[0040] Such as figure 1 As shown, the present embodiment provides a technical solution: a method for processing a multilayer microstrip plate based on a perovskite ceramic filled substrate, comprising the following steps:

[0041] (1) A multi-layer board based on perovskite ceramic filled microwave dielectric board is obtained by lamination, and the inner wall of the blind slot or the side wall of the through slot is obtained by mechanical milling;

[0042] (2) Activate and modify the inner wall of the blind groove or the side wall of the shape of the through groove;

[0043] (3) Micro-etch the inner wall of the blind groove or the side wall of the through groove; improve the adhesion of the copper plating;

[0044] (4) Electroless copper plating is performed on the inner wall of the blind slot or the side wall of the through slot;

[0045] (5) Electroplating copper is thickened on electroless copper plating;

[0046] (6) Carry out surface coating together with the whole pl...

Embodiment 2

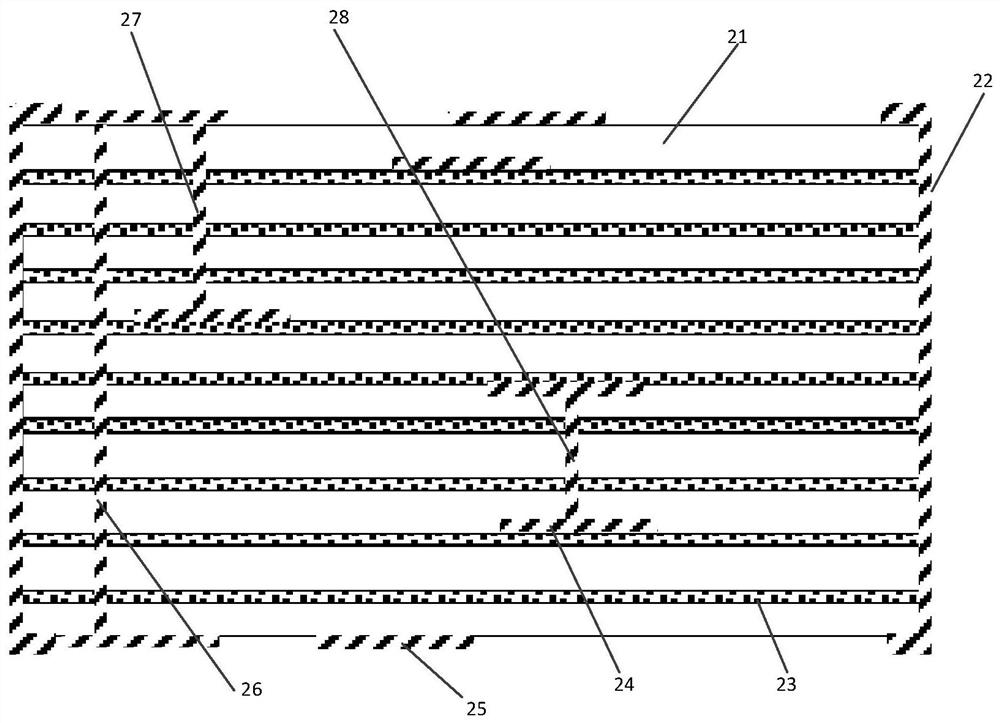

[0072] Such as figure 2 Shown is a schematic diagram of metallization on the side of the shape in this embodiment. The semi-finished 20-layer microstrip board after lamination includes: 10 layers of microwave dielectric board 21 based on perovskite ceramic filling with a dielectric constant of 6.15, adhesive material 23 (thermosetting adhesive film made of Fastrise 28), and blind holes 27 , Buried hole 28, through hole 26, inner layer pattern 24. According to the processing parameters in Table 1, the through grooves on the 8-piece 1 working board are obtained (8-piece 1 means that 8 semi-finished microstrip boards are put together, and the through groove refers to the through groove formed between the semi-finished microstrip boards).

[0073] Plasma treatment is performed on the through hole 26 and the through groove according to the parameters in Table 1. The comparison of the implementation effect after plasma treatment is shown in the figure Figure 4 As shown, the hyd...

Embodiment 3

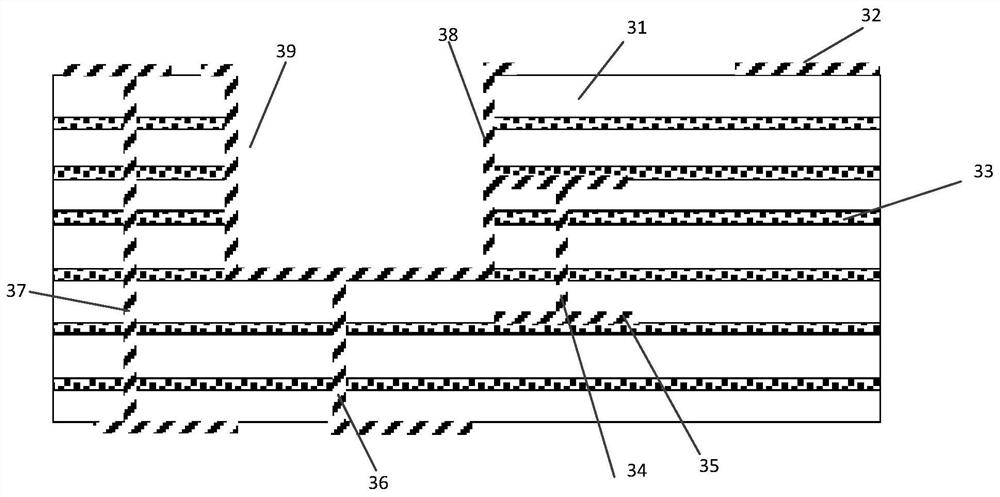

[0075] Such as image 3 As shown, it is a schematic diagram of the side metallization of the inner wall of the blind groove in this embodiment. The semi-finished product of the fourteen-layer microstrip board after lamination includes: seven-layer microwave dielectric board 31 based on perovskite ceramic filling with a dielectric constant of 10.20, adhesive material 33 (thermosetting adhesive film made of 2929 material), buried hole 34 , Through hole 37, inner pattern 35. According to the processing parameters in Table 1, the blind groove 39 and the blind hole 36 on the 12-piece 1 working board are obtained (12 pieces together are 12 semi-finished microstrip boards together), and the blind groove 39 is made by adhesive tape blocking glue opening method craft. The plasma treatment is performed on the through hole 37 and the blind groove 39 according to the parameters in Table 1. Then perform plasma microetching according to the parameters in Table 1, and then perform electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com