A kind of environment-friendly plastic bag and preparation method thereof

A plastic bag, environmentally friendly technology, applied in the field of packaging bags, can solve the problems of consuming a large amount of food and affecting the normal application of food, and achieve the effect of accelerating the degradation speed, improving the mechanical properties and water resistance, and being easy to degrade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of preparation method of environment-friendly plastic bag:

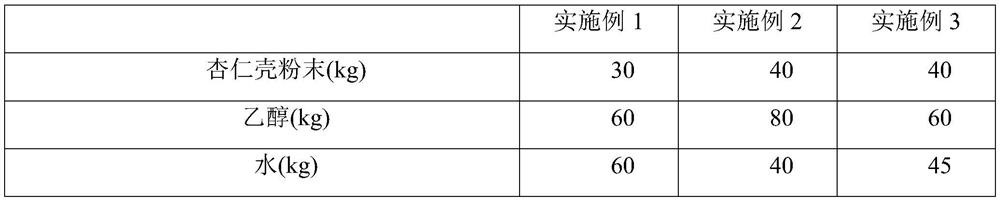

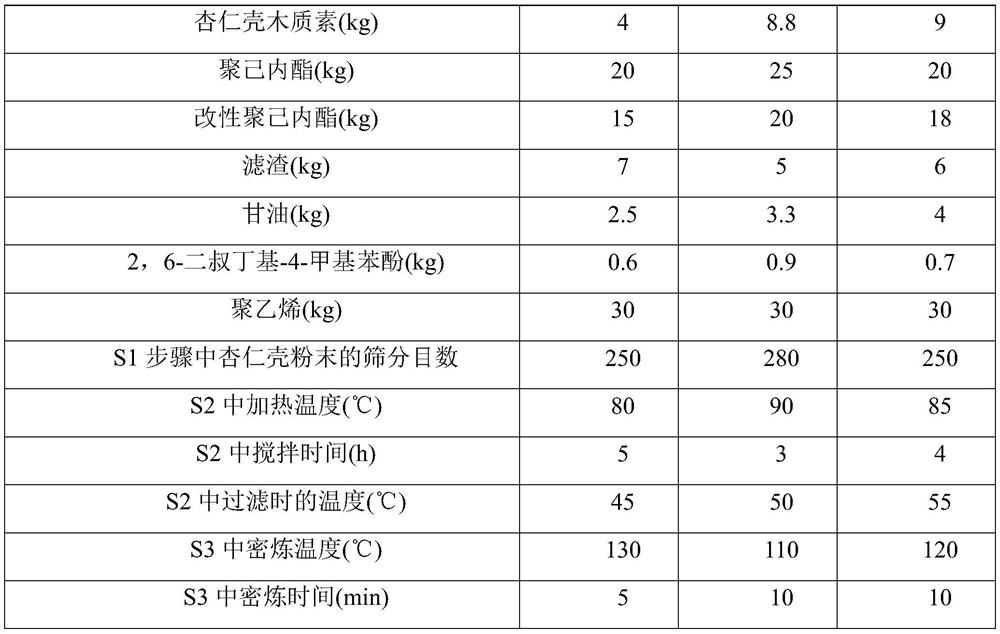

[0046] S1. crush the almond shells with a pulverizer until the almond shells can pass through a 250-mesh sieve to obtain almond shell powder;

[0047] S2. Add 30kg of almond shell powder, 60kg of ethanol and 60kg of water into the reactor, mix and stir, heat to 80°C, stir for 5h, cool to 45°C after stirring, filter, separate the filtrate and filter residue, wherein the filter residue is at 50°C drying in an oven for 1 hour, and set aside; the filtrate was evaporated to dryness, and then dried in an oven at 50°C for 1 hour to obtain almond shell lignin;

[0048] S3. Add 4kg of almond shell lignin and 20kg of polycaprolactone into the internal mixer and mix them, banbury at 130°C for 5min, extrude and granulate with an extruder to obtain modified polycaprolactone;

[0049] S4. Add 15kg modified polycaprolactone, 7kg filter residue, 2.5kg glycerin and 0.6kg 2,6-di-tert-butyl-4-methylphenol into the mixer ...

Embodiment 2

[0051] A kind of preparation method of environment-friendly plastic bag:

[0052] S1. crush the almond shells with a pulverizer until the almond shells can pass through a 280-mesh sieve to obtain almond shell powder;

[0053] S2. Add 40kg of almond shell powder, 80kg of ethanol and 40kg of water into the reactor and mix and stir, heat to 90°C, stir for 3 hours, cool to 50°C after stirring, filter, separate the filtrate and filter residue, wherein the filter residue is at 50°C drying in an oven for 1 hour, and set aside; the filtrate was evaporated to dryness, and then dried in an oven at 50°C for 1 hour to obtain almond shell lignin;

[0054]S3. Add 8.8kg of almond shell lignin and 25kg of polycaprolactone into the internal mixer to mix, banbury at 110°C for 10min, extrude and granulate with an extruder to obtain modified polycaprolactone;

[0055] S4. Add 20kg modified polycaprolactone, 5kg filter residue, 3.3kg glycerin and 0.9kg 2,6-di-tert-butyl-4-methylphenol into the mi...

Embodiment 3

[0057] A kind of preparation method of environment-friendly plastic bag:

[0058] S1. crush the almond shells with a pulverizer until the almond shells can pass through a 250-mesh sieve to obtain almond shell powder;

[0059] S2. Add 40kg of almond shell powder, 60kg of ethanol and 45kg of water into the reactor, mix and stir, heat to 85°C, stir for 4 hours, cool to 55°C after stirring, filter, and separate the filtrate and filter residue, wherein the filter residue is at 50°C drying in an oven for 1 hour, and set aside; the filtrate was evaporated to dryness, and then dried in an oven at 50°C for 1 hour to obtain almond shell lignin;

[0060] S3. Add 9kg of almond shell lignin and 20kg of polycaprolactone into the internal mixer to mix, banbury at 120°C for 10min, extrude and granulate with an extruder to obtain modified polycaprolactone;

[0061] S4. 18kg modified polycaprolactone, 6kg filter residue, 4kg glycerin and 0.7kg 2,6-di-tert-butyl-4-methylphenol are added in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com